Digital production

Tailored digital solutions from the edge to enterprise, addressing current operational demands and paving the way for a more resilient future

Move confidently, ahead of time

Addressing your production challenges becomes much easier, when you have a clear view of the entire value chain. By integrating your data and workflows with advanced AI, you build a unified perspective, helping you move from reactive operations to having real control. You gain the power to enhance production and throughput by solving issues ahead of time—before they become problems.

Solve the production balancing act

When it comes to balancing the need to optimize production, processing and transportation, control costs, and reduce emissions, we work closely with you to deliver solutions. We can help you reduce equipment downtime, improve decision making and tackle the hidden inefficiencies ingrained in outdated work processes. Our modular solutions mold to your operations, scaling effortlessly from a single well or piece of equipment to an entire facility or production enterprise.

Unlock the promise of digital

We have fused evergreen data and models with advanced AI to deliver unparalleled foresight you can trust:- Focus on right-time decisions and actions to enhance production.

- Cut travel to remote sites.

- Provide a shared view of today’s reality for better outcomes.

- Break data silos.

- Scale digital deployments.

Production operations

Fueled by IoT and edge computing, significantly reduce the time from event to resolution, and progress toward closed-loop autonomy. Anticipate and execute the tasks that matter most—in real time, in time, all the time.

Production assurance

A combination of deep science and AI that goes beyond analytics, providing insights, and advisory systems. You can ensure a continuous flow of molecules from the wellbore, through the entire production system, to enhance production efficiency and reliability.

Asset performance

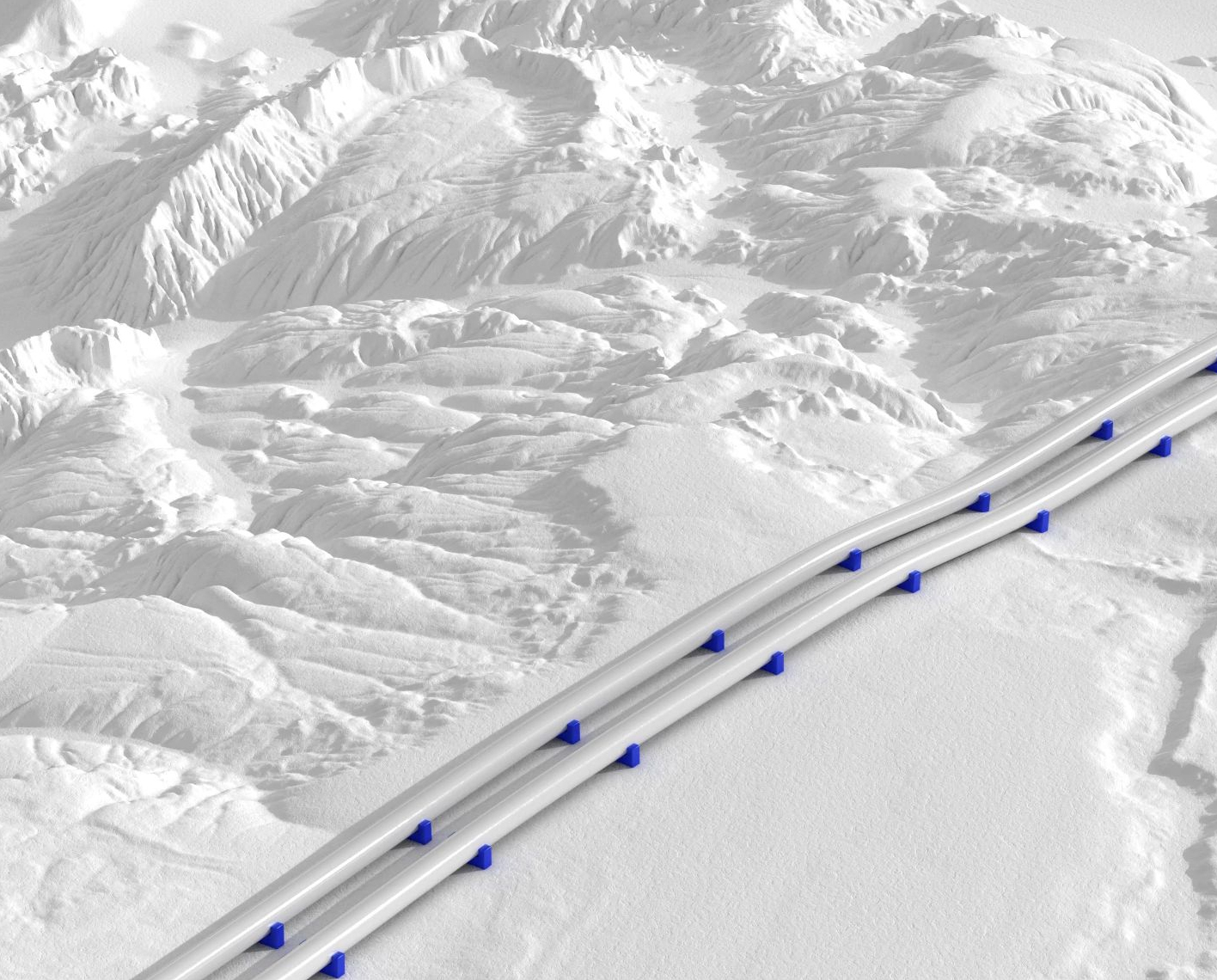

A step-change in facility and pipeline operations for enhanced speed and accuracy through an innovative new ecosystem of solutions.

Operations data

Industry-leading data and AI solutions and services enable the integration of digital capabilities with your existing infrastructure to drive superior production, facility performance, and operational efficiency.

Explore our solutions

Production operations

Anticipate and execute the tasks that matters the most with edge computing—in real time, in time, all the time

Production assurance

Ensure uninterrupted production operations, mitigate risks, and optimize efficiency for optimal productivity

Facilities, Equipment, and Pipelines

Groundbreaking digital solutions to streamline facility and pipeline operations and deliver a step-change in performance to enhance efficiency, reduce footprint, increase throughput, and avoid unexpected events

Operations data

Industry-leading data and AI enablers and digital production solutions to drive superior performance

Flow Assurance and Production Webinar Series

Related Products

-

OptiSite

Facility, equipment and pipeline solutionsEmbrace a new level of integration and insight for proactive, ‘big picture’ asset performance improvements.

-

OptiFlow

Production assurance solutionsAmplify operational efficiency through continuous surveillance, streamlined well-network flow, and optimized resources.

-

Symmetry process simulation software

Improve safety, profits, and performance by optimizing process workflows in one platform.Improve safety, profits, and performance by optimizing process workflows in one platform.

-

Lumi operations data foundation

Groundbreaking data operations solution that powers domain and AI-driven workflows across production operations at scaleGroundbreaking data operations solution that powers domain and AI-driven workflows across production operations at scale.

-

Physics-Informed AI

Simulation-quality insight with the speed and flexibility of AIPhysics-informed AI is a breakthrough hybrid model building technique, that fuses physics-based simulation and process data.

-

Facilities, Equipment, and Pipelines

Groundbreaking digital solutions to streamline facility and pipeline operations and deliver a step-change in performance to enhance efficiency, reduce footprint, increase throughput, and avoid unexpected eventsGroundbreaking digital solutions.

-

Production Engineer on Delfi

Steady-state and transient simulations of well and surface facilitiesTools for steady-state and transient simulations of well and surface facilities to identify and mitigate flow assurance challenges.