OptiFlow

Production assurance solutions

Amplify operational efficiency through continuous surveillance, streamlined well-network flow, and optimized resources.

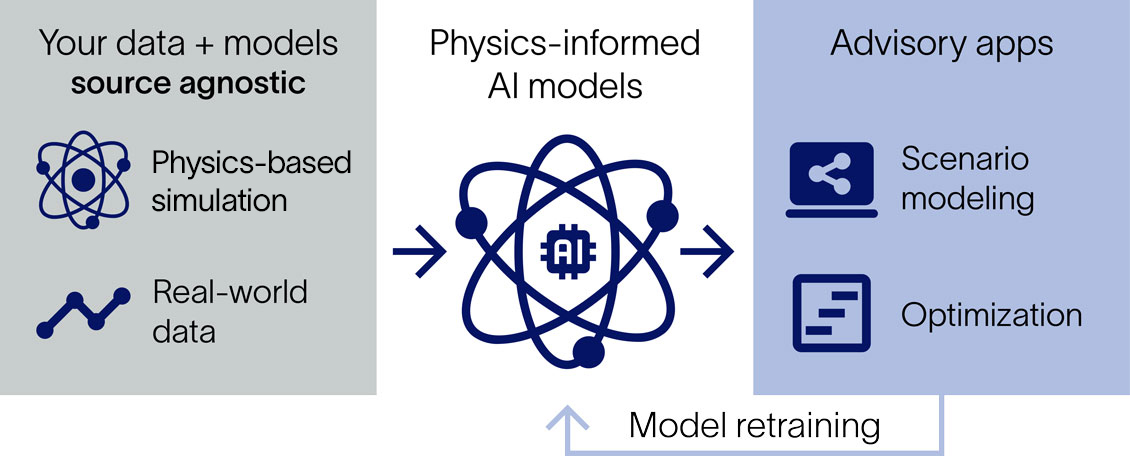

Optimizing complex production and process systems requires accuracy in real-time. Traditional oil and gas operations rely on expertise limitations, siloed working, and slow, non-continuous optimization to operate assets. This leads to excess carbon emissions, process inefficiency, and new net zero technologies that are economically unfeasible. AI offers promise however, training data availability is typically very limited. The non-linear behavior of systems is difficult to capture, and contextual understanding is required to address previously unseen conditions.

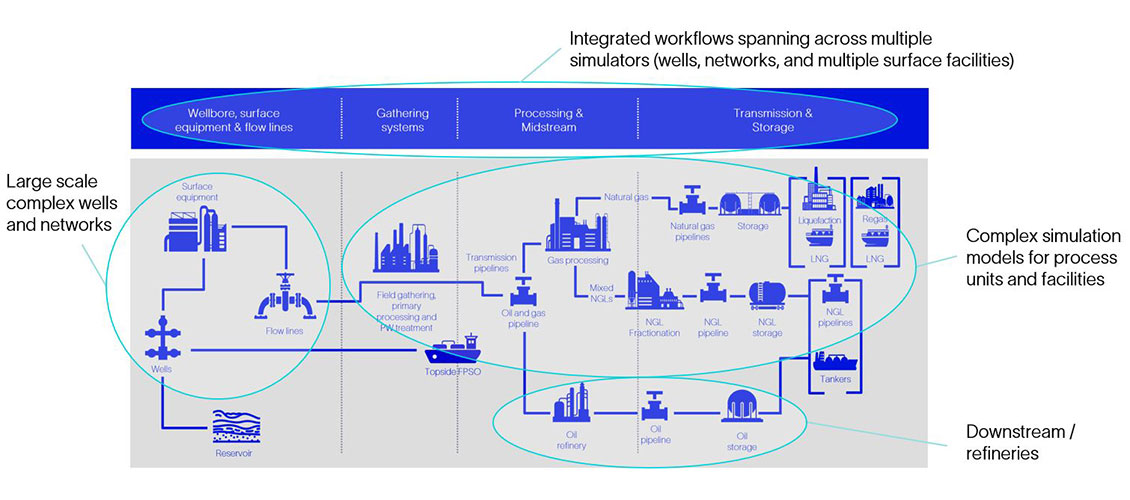

Physics-informed AI addresses these challenges, by performing predictive, real-time optimization for a wide spectrum of complex systems across upstream, midstream, and downstream operations.

The solution delivers scientifically consistent results, captures system dynamics, delivers interpretable results, and typically solves orders of magnitude faster than physics-only simulators.

Physics-informed AI optimizes complex oil and gas production and process systems in real time across a wide range of scenarios.

Proof of value has been clearly established in a wide range of case references, including methanol injection optimization, liquid slug mitigation, electric submersible pump (ESP) power optimization, natural gas liquids (NGL) processing, and gas-oil separation plant (GOSP) optimization. Results include:

Think of physics-informed AI (PI-AI) as AI for engineering workflows, helping engineers make better decisions faster, reduce risks, and improve efficiency. PI-AI is a type of hybrid AI that blends data and physics. Instead of relying only on data, it also uses scientific ‘first principles.’ A neural network is constructed using physics equations or models to learn solutions to problems, like temperature over time or fluid velocity. Instead of just minimizing the error between predictions and data, the PI-AI model minimizes how much it violates the laws of physics. It learns to fit the data and obey physics at the same time.

Traditional AI needs a lot of data to learn, and it can make mistakes if the data is noisy or incomplete. By adding physics into the mix, the AI is "guided" by known scientific rules, which helps it make more accurate and trustworthy predictions—even when data is limited.

The results are better informed, and enable more reliable predictions that can be executed in a fraction of the time compared to the update and execution of a traditional physics-based simulation model. PI-AI is particularly effective when applied in operational environments, where it:

PI-AI solutions are sometimes known as physics-informed machine learning (PI-ML) or physics-informed neural networks (PI-NN), and they have some key differences in approach versus black box AI models that do not give explainable results.

| Black-Box ML | Physics-Informed AI (PI-AI) |

|

|

There are multiple applications for PI-AI, it can be used anywhere that physics plays a key role. For complex oil and gas optimization scenarios, PI-AI can unlock value across the full E&P life cycle, and it can be applied in areas like carbon capture, geothermal energy, and manufacturing.

No. SLB, working with our partner, Geminus AI, designs its software interfaces so that engineers and domain experts can use PI-AI-powered tools without needing deep AI knowledge. The goal is to make advanced technology accessible and useful for everyday decision-making.

PI-AI solutions can be run standalone or accessed through SLB software platforms and solutions, on-premises or on the cloud. PI-AI solutions are delivered as a packaged offering, providing the domain support, implementation expertise and training you need to realize value quickly. Deployments are designed to deliver value to you within days or weeks.

Traditional physics-based simulation models can take hours or even days to run, especially in complex industrial systems. PI-AI allows engineers and operators to instantly evaluate what-if scenarios, respond to changing conditions, and continuously optimize operations—without relying on slow simulation cycles. The result: faster, smarter decision-making powered by hybrid AI that blends data and physics.

SLB and Geminus offer a unique PI-AI solution that combines deep domain expertise with scalable, hybrid AI models. Unlike traditional black box AI, our approach blends real-world industrial data with first-principles physics to create highly accurate, explainable models. This lets engineers—not just data scientists—build and deploy AI for engineering workflows faster, with less data. Our solution is built for real-time performance, enabling smarter decisions and measurable impact across industrial operations. Learn more about the science behind the approach in this in-depth article from SLB and Geminus.

PI-AI supports sustainability goals by improving operational efficiency, reducing energy use, and minimizing emissions. As a hybrid AI approach that blends physics and data, PI-AI enables accurate, real-time forecasting and optimization, making it ideal for industrial sectors like oil and gas, power, and manufacturing.

Highly flexible and portable— applicable to a myriad of use cases.

Agnostic to source and suitable even when data sets are sparse.

Multi-fidelity hybrid models that maximize the accuracy of model estimates.

Models adapt as systems and operating conditions change.

Explainable AI, with uncertainty quantified.

Models in hours, not months.

From concept to delivery in weeks, with easy deployment.

Repeatable techniques, speed model creation, and re-training.