Physics-Informed AI

Simulation-quality insight with the speed and flexibility of AI

Physics-informed AI is a breakthrough hybrid model building technique, that fuses physics-based simulation and process data.

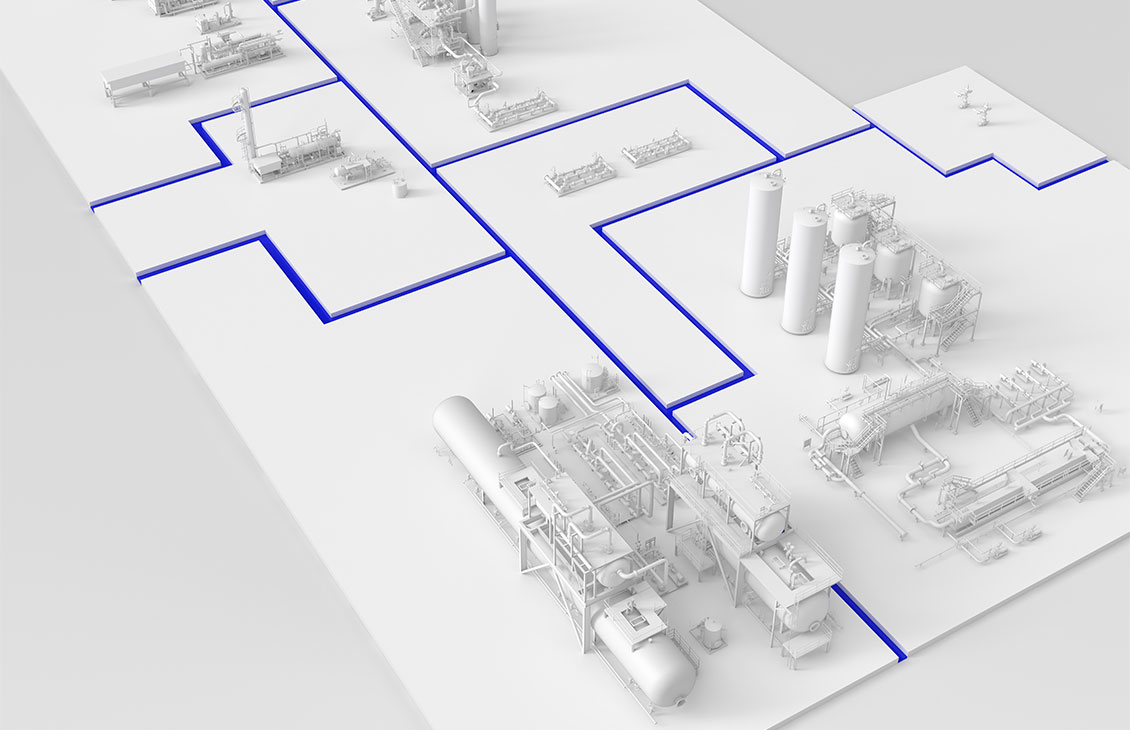

OptiSite™ facility, equipment, and pipeline solutions use advanced AI-driven digital tools to break down operational silos and increase proactivity. By providing real-time insights and automation, OptiSite solutions helps teams anticipate and address issues before they escalate, which leads to improved efficiency, increased throughput, and reduced downtime. These configurable solutions can be applied to individual assets or entire facilities, supporting sustainable operations by cutting unnecessary maintenance, lowering energy consumption, and enhancing safety from reduced personnel time on site.

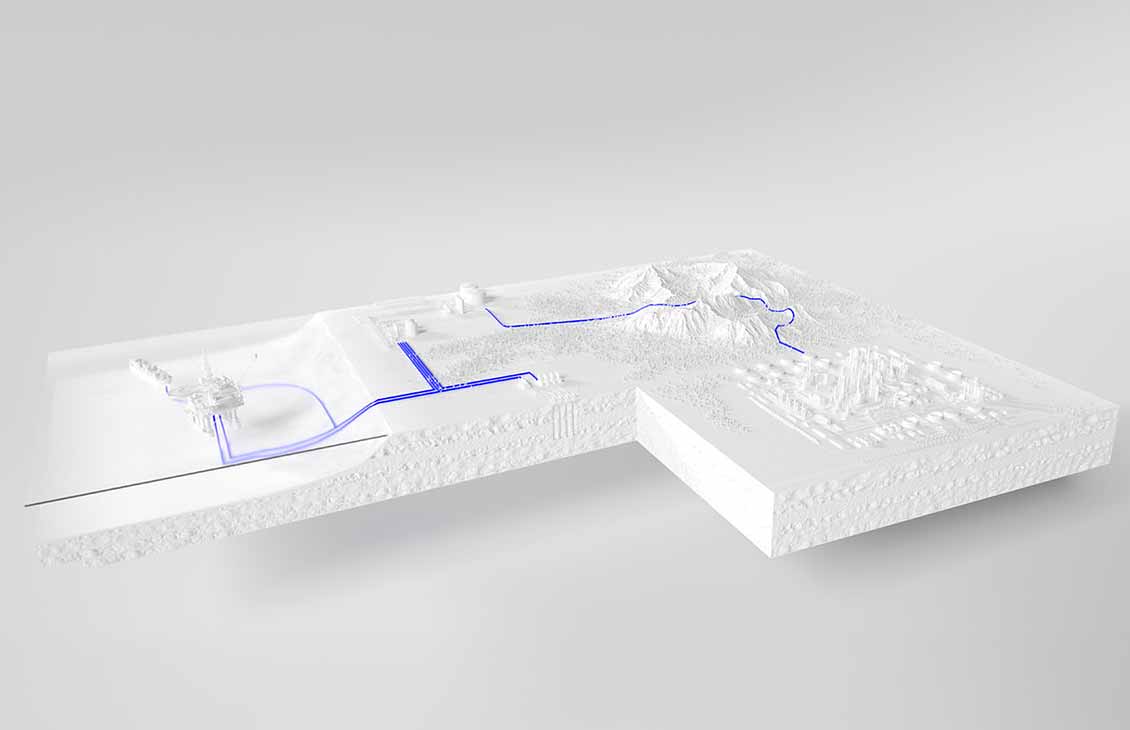

To enable optimization and predictive intelligence across production systems, OptiSite works seamlessly with OptiFlow™ production assurance solutions, as an integrated offering. By connecting facility, equipment and pipeline data with production assurance insights, teams can break down operational silos and gain a unified, real-time view of their operations. This integrated approach is underpinned by the Lumi™ operations data foundation—a platform that leverages advanced industrial data operations capabilities from Cognite Data Fusion®. Through this foundation, OptiSite and OptiFlow solutions can unite fluid flow and physical production system data and workflows, unlocking new opportunities for proactive, data-driven decision-making.

Tela™ agentic-AI assistant is designed to enhance the capabilities of OptiSite and OptiFlow solutions. Tela operates in a continuous loop of observing, planning, generating, acting, and learning—helping to streamline operations and drive smarter outcomes.

Digital twins of your processing equipment and facilities

Facility uptime management and equipment twin analysis models

Predictive monitoring, inspection and modeling solutions

Breaking down traditional data and organizational barriers

Field worker digitalization and autonomous robotic operations

Drive performance, retain talent, align DPIs, and transparent communication.

Actionable insights, model scenarios, and optimize production.

Find improvements, reduce OPEX, and predict equipment reliability.

Run complex models, test scenarios, and optimize in real time with AI.

Make better decisions through better collaboration and AI-driven insights.

Streamline maintenance with actionable guidance.

Maximize ROI from your existing investments in data infrastructure and systems.

Enhance efficiency, streamline workflows, and provide effective support for your personnel.

Enhance production throughput, reduce costs, and maximize revenue.

Enhance safety, reduce energy consumption and emissions.

Discover the latest developments.

Further recent enhancements in deployment flexibility and scalability ensure rapid deployment, delivering actionable insights securely within just weeks.

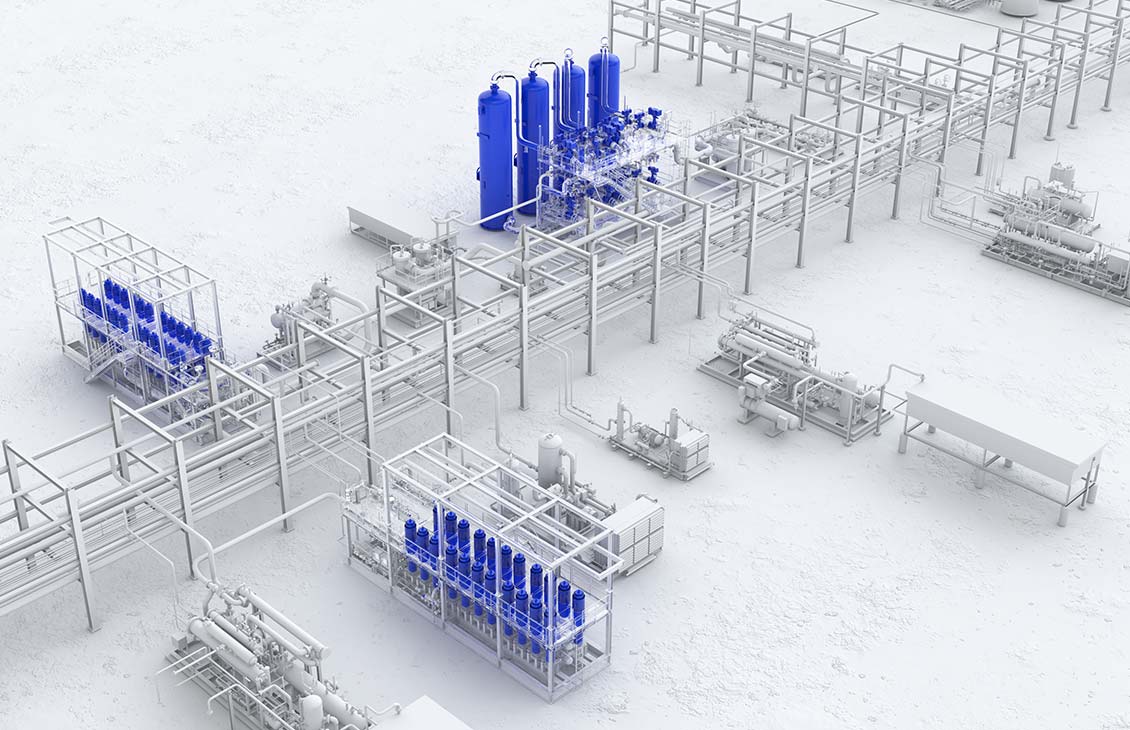

Native support of physics-informed AI models enables fast and robust process optimization workflows. Additional robustness around risk, integrated corrosion, and enhanced pattern recognition have been added to solutions for pipeline integrity and autonomous robotic operations.

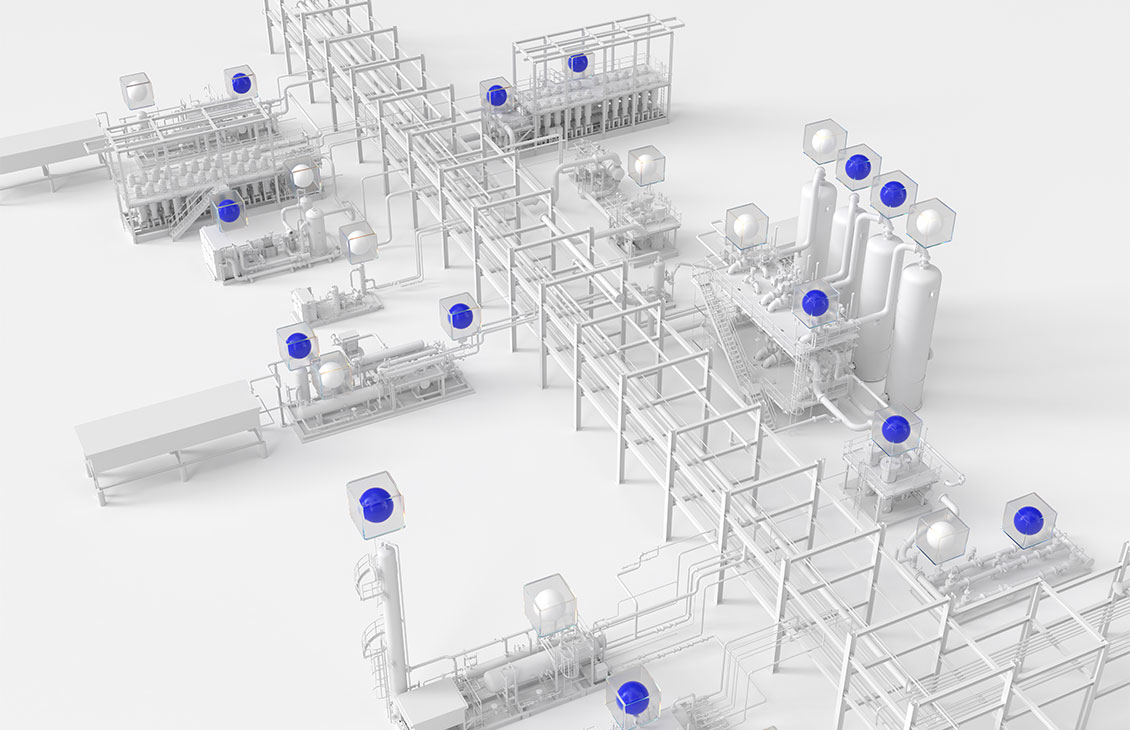

OptiSite solutions insights and actions combine equipment digital twins with data in context regardless of source. The library of equipment twins from SLB and third party equipment providers has been expanded in 2025.

With the combination of data, domain knowledge, and generative AI, natural language questions can be used to optimize asset performance. These AI assistants analyze the asset's behavior, before suggesting targeted actions.

Yes. However, the OptiSite™ facility, equipment, and pipeline solutions are not traditional solutions, they are different in several ways:

OptiSite solutions are powered by the Lumi Operations Data Foundation, which transforms siloed data into accessible, contextual information from across IT, operations technology, and engineering technology data sources. OptiSite solutions provides continuous access to operational data, including from legacy systems to ensure that data integration is seamless and comprehensive. The solutions’ digital twins pair with AI to rapidly transform comprehensive data streams into actionable insights, allowing for real-time optimization and predictive maintenance. They employ AI and machine learning to analyze data from multiple sources, providing predictive failure models, anomaly detection, and condition monitoring. This helps in proactively preventing downtime and swiftly resolving issues.:

OptiSite solutions leverage AI and machine learning to significantly enhance predictive maintenance through several key mechanisms:

Learn from our experts in this on-demand SPE Tech Talk about new configurable, scalable digital solutions in a collaborative environment for optimizing your production and pipeline performance.

Watch now

Transform equipment and facility operations with new generation digital solutions.

Revolutionize equipment and facility management with new generation solutions.

Integrated AI drives predictive data-driven solutions for pipeline monitoring.

An out-of-the-box solution that breaks down silos.

Field worker digitalization and autonomous robotic operations.

From design through operations.