Separate acid gases from produced natural gas without chemicals.

Higher production and hydrocarbon recovery with retrofitted CO2 separation membranes

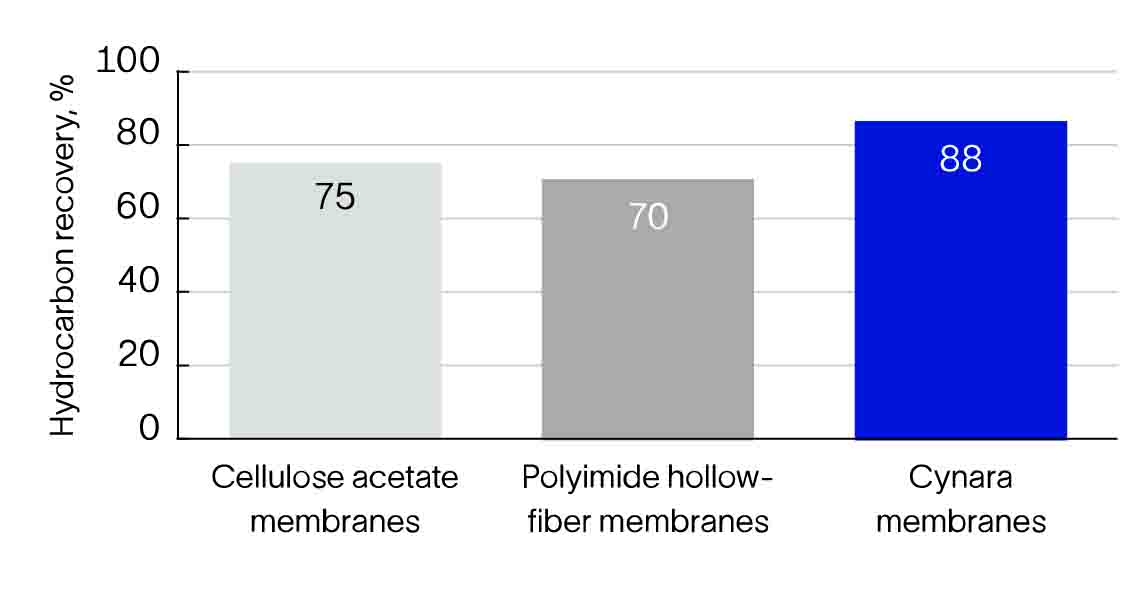

Following the introduction of gas from a new well, CO2 separation membrane performance at a natural gas processing facility declined, resulting in 35% decrease in production. Cynara™ H2S and CO2 separation membranes provided a plug-in solution that restored production capacity and improved hydrocarbon recovery by 13 percentage points, reducing CO2e emissions.

Emissions reduction

Reduced hydrocarbons lost with the permeate CO2 by >50%

A natural gas processing facility in Western Australia was using cellulose acetate spiral-wound membranes to sweeten the incoming gas from nearby wells. When a new well was brought online, the altered hydrocarbon composition caused membrane performance to decline, and gas production fell to 65% of design capacity.

Seeking an alternative solution that did not require infrastructure adjustments, the operator selected polyimide hollow-fiber membranes from a third party who offered an accelerated delivery timeline. However, when the plant was brought back online, production was even lower—just 40% of the design basis.

The operator reached out to SLB, which recommended its proven cellulose triacetate hollow-fiber Cynara membrane for acid gas removal. Horizontally oriented Cynara membrane elements are designed for retrofitting existing membrane installations to improve separation performance. Their packaging enables simple plug-and-play replacement without infrastructure modifications. The membranes were introduced using a phased strategy, and delivery, installation, and commissioning were completed without incident.

Performance improvement was almost immediate, and the plant was soon producing at 100% capacity. The amount of hydrocarbons lost with the CO2 permeate has also reduced; hydrocarbon recovery is 13 percentage points higher compared with the original cellulose acetate membranes and 18 percentage points higher versus the polyimide hollow-fiber membranes (with performance variable on the basis of process conditions). Both factors have increased energy delivery to the Western Australian market. The greater hydrocarbon retention in the product gas stream has reduced CO2e emissions. At the same time, the resulting higher-purity CO2 outlet stream has enabled the operator to actively pursue carbon capture and sequestration (CCS) and further reduce the plant’s carbon footprint.

"The Cynara membrane elements were expected to be far less susceptible to the hydrocarbon composition issues that impacted the polyimide elements—with process issues resulting in increased C6+ components. The prompt supply of an initial batch of elements allowed for prompt performance testing and confirmation that the Cynara membrane elements were able to achieve the desired rates prior to full replacement of the polyimide elements. Ongoing support from the SLB technical team was also able to provide meaningful input to the upstream performance issues with the facility, helping to ensure optimal membrane performance, allowing facility production to be optimized."

—Gas Plant Senior Process Engineer