Environmental impact quantification

Support United Nations Sustainable Development Goals (SDGs) with proven impact-reducing Transition Technologies

Drive high performance while showing tangible footprint reduction

Fossil fuels have been our primary energy source for the last century. But the current approach we use to produce and consume these resources is not sustainable for the planet. As energy demand grows and net-zero emissions targets become key value drivers, we need to drive the transition to lower-emitting energy systems without compromising energy supply. The oil and gas industry will have a key role in addressing this challenge. That’s why we're committed to helping our customers reduce emissions and environmental footprint and to transparently showing the impact we can make together.

We deliver technologies that are proven to quantifiably reduce impact now and drive more sustainable decisions for the future.

Our methodology

Our team of engineers have worked to quantify and prove the impact of our Transition Technologies. To do this, we developed a scientific methodology to consistently measure their sustainability impact on operations across the oil and gas value chain. The method enables us to identify and quantify the impact of current technologies and guides our development process for new ones.

Having a consistent quantification methodology is fundamental to our approach. It builds on existing industry standards, guidelines, and data (GHG Protocol, ISO 14040, and others) combined with those more uniquely suited to our operations. It's based on four fundamentals:

Credibility

We aim for transparency of scope and data utilization with external verification where possible.

Reference

We compare technologies with equivalent ones to define value-driver threshold.

Attributes

We map technology impacts to attributes, such as emissions reduction, which support the UN SDGs.

Life Cycle

We identify and quantify all impactful phases within the technology life cycle.

Supporting the energy transition and UN SDGs

Many oil and gas stakeholders communicate sustainability objectives through an SDG lens. Our methodology categorizes the environmental benefits of our technologies and links them to relevant UN SDGs.

- Reduce emissions from operations

- Promote high efficiency and reduce energy consumption

- Electrify infrastructure, minimize footprint, and enable access to renewable power

- Measure, monitor, and assess operations to minimize impact

- Incorporate cleaner chemicals and reduce use of hazardous materials

- Minimize pollution and promote good water stewardship

- Minimize waste during operations

- Reduce the physical size of projects

The eight attributes we have defined more easily enable impact quantification and facilitate embedding methodology into our R&D process.

Our commitment to lower carbon emissions

In 2021, SLB committed to net-zero emissions by 2050 across Scopes 1, 2, and 3 in line with climate science and the Greenhouse Gas Protocol. Our target supports the ambitions of the Paris Agreement, developed by the United Nations Framework Convention on Climate Change (UNFCCC), which seeks to reduce greenhouse gas (GHG) emissions by pursuing efforts to limit global warming to 1.5 degC above preindustrial levels.

How can we partner to help you reach your sustainability goals?

Our Transition Technologies address sustainability challenges and opportunities across oil and gas operations. This growing portfolio delivers solutions and quantifies impact no matter where you are in the hydrocarbon life cycle.

-

Decarbonize Drilling and Completions

Build upstream oil and gas infrastructure with a lower carbon footprintReduce the footprint of oil and gas operations.

-

Eliminate Methane and Flaring Emissions

Decarbonize operations by addressing large sources of greenhouse gasesStart with a plan, the right technologies, and a partner you can trust.

-

Decarbonize Oil and Gas Production

Leverage technologies and solutions that reduce GHG emissions per barrel producedGet closer to the action.

Case studies

-

Case Study: Improving Efficiency With Fewer Trips Lowers Rig Emissions

NeoSteer CL ABSS drills a single-run curve and lateral, reducing a customer’s rig time and carbon footprint.

-

Case Study: Fiber Optics Reduces Acquisition Time and CO2e Emissions

Optiq Seismic borehole seismic solution avoided deferred production and reduced a customer’s energy consumption.

-

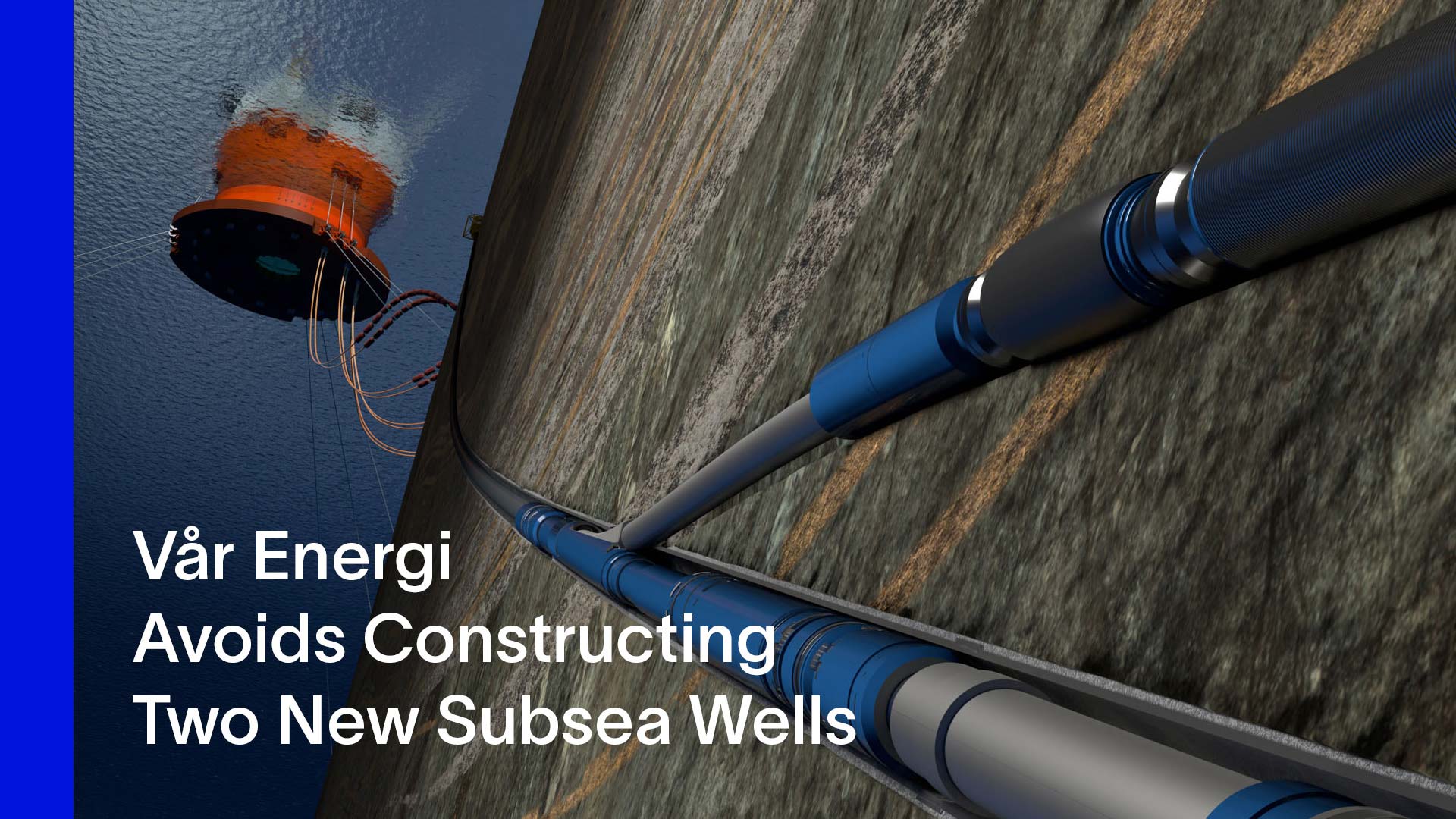

Case Study: Vår Energi Avoids Constructing Two New Subsea Wells

Retrofitting two wells as multilaterals avoided adding infrastructure, reducing our customer’s GHG emissions.