Cementing services

Achieve long-term zonal isolation in any environment

Cement supports and protects well casings and helps achieve zonal isolation. Critical to safer, environmentally sound, and profitable wells, zonal isolation is created and maintained in the wellbore by the cementing process. Whatever your drilling environment or however remote the location, our innovative cementing technologies offer you a range of cementing solutions to achieve zonal isolation for the life of your well.

Our technology portfolio includes cement-free systems to increase sustainability and decarbonize your operations.

Alternatives to portland cement-based systems.

Cement Solutions

Achieve zonal isolation for the life of your well.

-

CemBoost

US-land high-performance cementCemBoost cement achieves faster compressive strength, reducing WOC time so you can start drilling faster

-

Adaptive Cement Systems

Maintain zonal isolation even as conditions varyEnsure well zonal integrity from drilling through abandonment with a competent annular pressure seal that prevents hydrocarbon leaks.

-

Gas Migration Control

Risk evaluation and tailored solutionsEffectively cement gas-bearing formations and prevent annular gas flow with proper density control, mud removal, and slurry design.

-

Deepwater Cementing Technologies

Ensure zonal isolation and casing integrityUnderstand deepwater technical challenges and design cementing solutions that meet deepwater specifications.

-

CemCRETE

Concrete-based oilwell cementing technologyDevelop high-quality cementing solutions for each type of well environment.

Noninvasively confirm annular barrier and bond between the casing and cement with acoustic sonic and ultrasonic insight.

Evaluate all parameters for the zonal isolation you require in all types of wells and casing.

Bridge thief zones that can lead to lost circulation while drilling and cementing.

Remove drilling fluids prior to cementing operations and achieve long-term zonal isolation.

Cementing Equipment

Cementing technology designed for the most challenging well environments.

-

Remote and Automated Cementing

Enhancing operational efficiency with automated remote cementing solutionsOptimize remote cementing operations with minimal human intervention and real-time data access.

-

Rig-Enabled Cementing Service

Improved efficiency through rig integrationSimplify maintenance, streamline job execution, and reduce logistics involved in the well construction process.

-

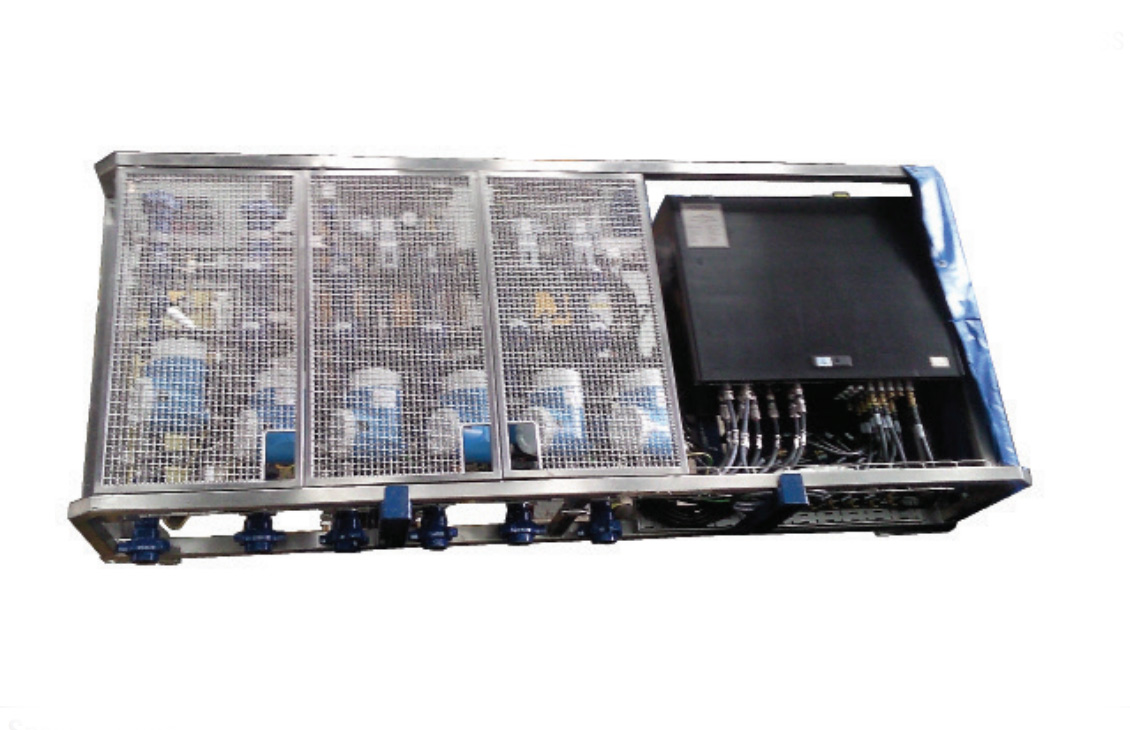

Skid-mounted cementing units

Increased mixing rate capabilitiesPerform high-pressure pumping services with increased mixing rates that minimize job time.

-

Batch mixers

Large-volume solutions for uniform cement slurryMix large volumes of uniform cement slurry and significantly reduce fluctuations in cement density.

-

Cement Trucks and Trailers

Rugged, low-maintenance cementing unitsSimplify operations year-round in harsh environments.

-

Liquid Additive Systems

Preprogrammable modular systemsPreprogram multiple additives and maintain additive concentrations with a high degree of accuracy.

-

SlurryAirSeparator

Mechanical cement slurry defoamerImprove slurry quality with environmental compliance, and eliminate foaming problems.

-

DeepSea EXPRES

Subsea cementing headImprove safety for remote operations and save time during rig-up and cementing execution.

-

SFM

Solids fraction monitorAchieve real-time slurry quality control.

-

External Casing Packer

Robust expandable stainless steel devicesDesigned to set at low pressures to achieve zonal isolation irrespective of hole shape and condition.

-

Annular Zonal Isolation Packers

Using expandable steel technologyMinimize costs and NPT with robust expandable steel annular packers for zonal isolation in open and cased holes.

Well integrity technology for plug and abandonment (P&A).