Carbon Storage MMV Planning

Develop compliant, cost-effective carbon storage MMV plans with SLB's industry-leading technology

Develop compliant, cost-effective carbon storage MMV plans with SLB's industry-leading technology.

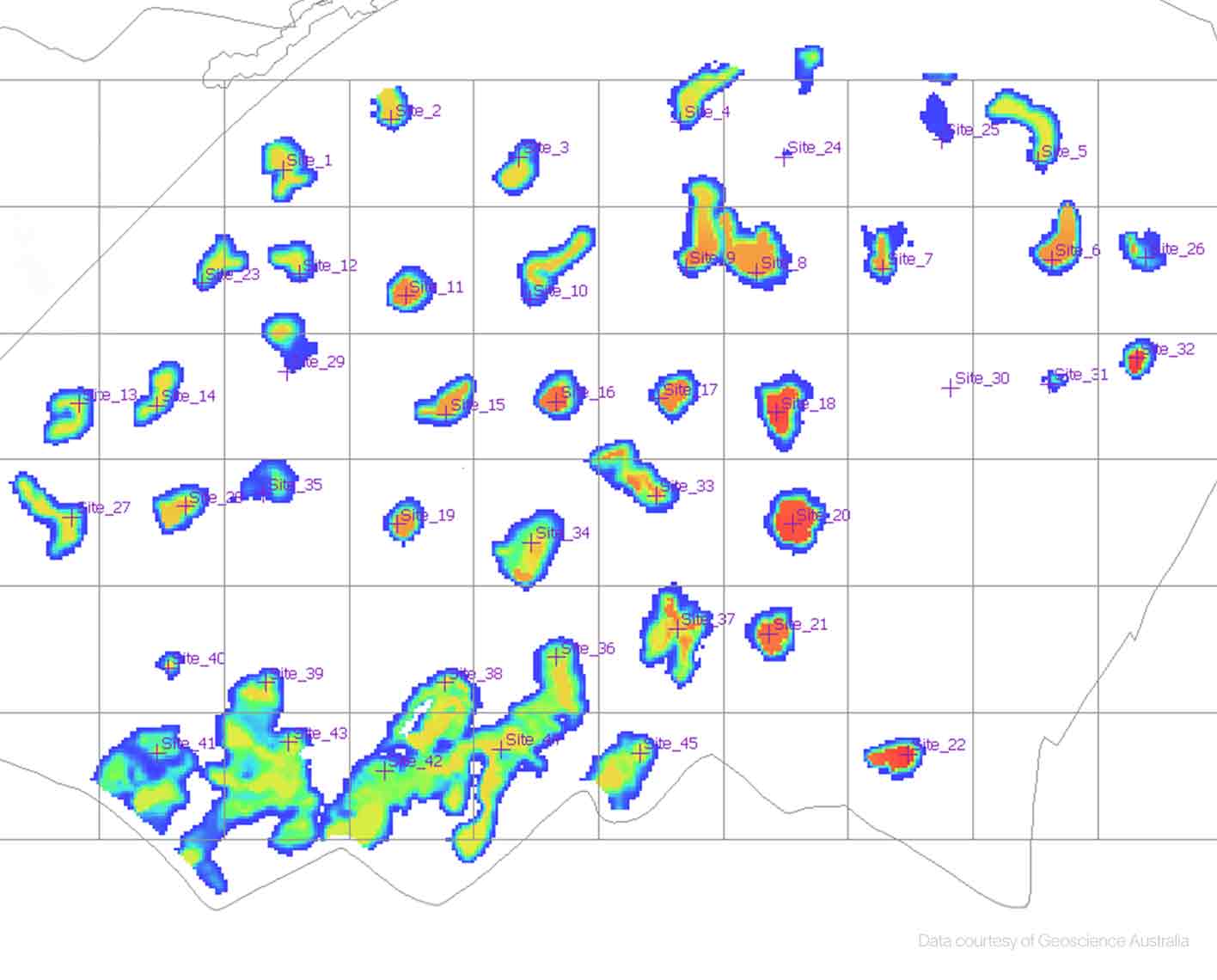

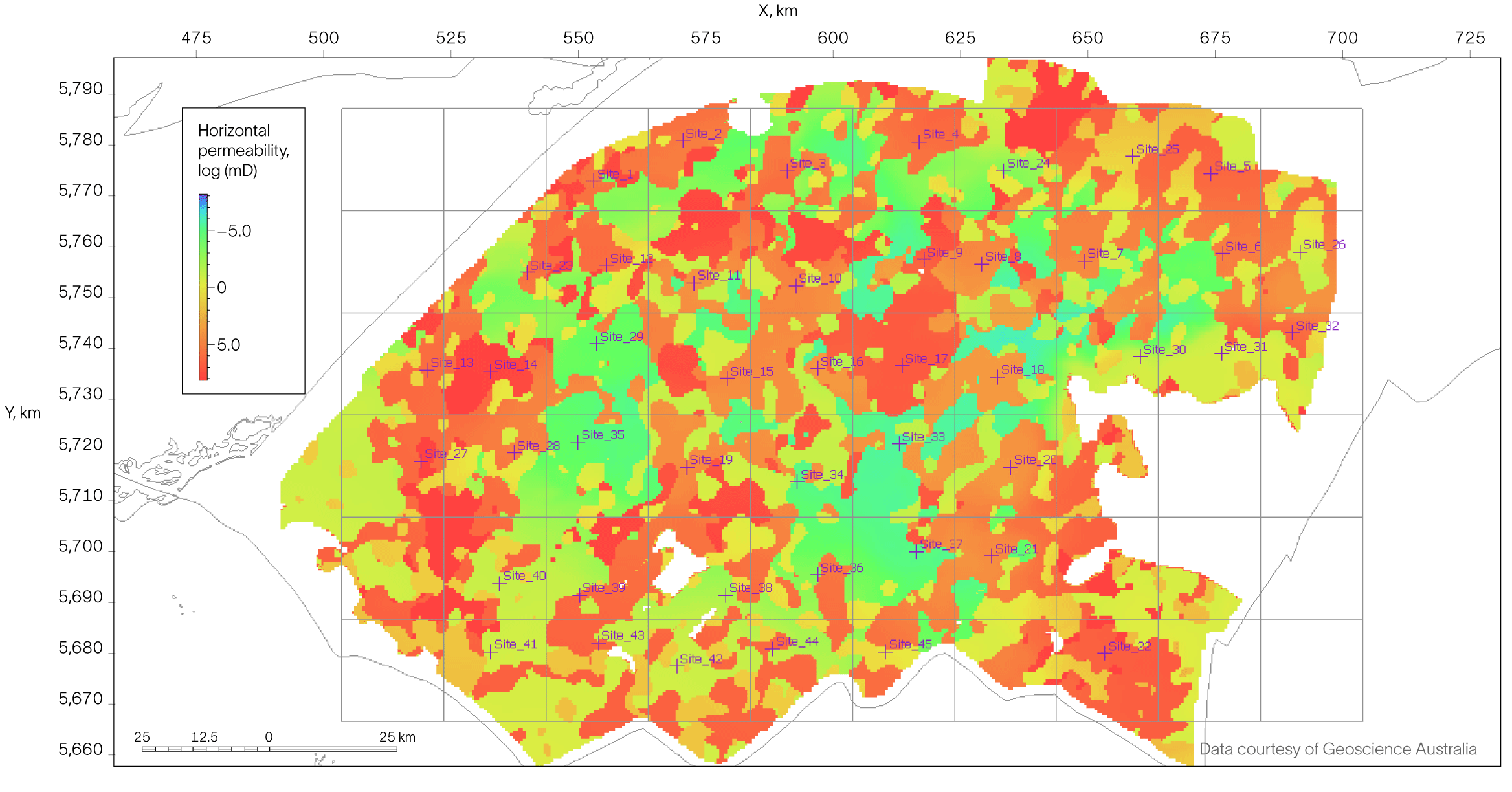

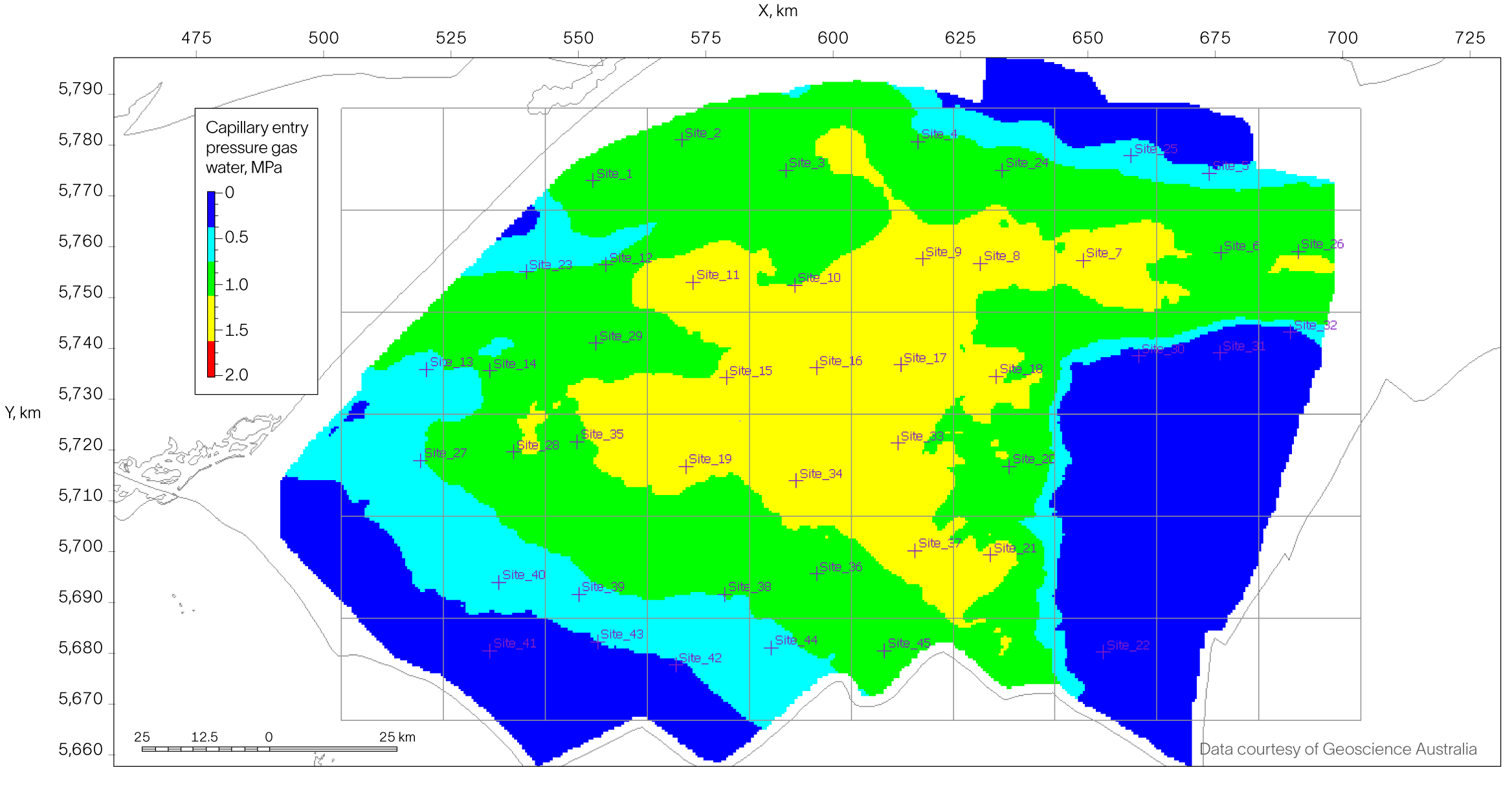

Detailed evaluation of your potential carbon storage site is crucial to assessing its long-term performance and project viability. SLB understands the complexities of identifying, evaluating, and considering the long-term requirements of carbon storage sites. These requirements include final monitoring, measurement, and verification (MMV) planning. The MMV plan must address direct and indirect measurements to demonstrate integrity of the storage site and conformance with the predicted CO2 migration models. The plan defines the technology selection that is best suited for the specific site and injection conditions and is based on evaluation of the associated risks. This is integral to the evaluation phase as risk mitigation and operating expenditure are key components in the project feasibility assessment.

Our Sequestri™ evaluation carbon storage solution is equipped to handle the uncertainties, sensitivities, and nuances of CO2 storage analysis. And our experts possess the knowledge and experience necessary to perform detailed assessments of storage performance, evaluate the most cost-effective models for site injection, and design MMV plans that will comply with regulations or other legal requirements. Additionally, we help streamline and optimize engineering iterations to final investment decision (FID), saving time and money and without increasing risk or compromising safety.

With experience in more than 120 CCUS projects, SLB has a proven track record of success in project management. We have supported projects through all life-cycle phases, from site screening and evaluation to design and operation of carbon storage sites. Our experience spans a diverse range of geologies across the globe—and we’ll apply our learnings from all of it to your CO2 storage project.