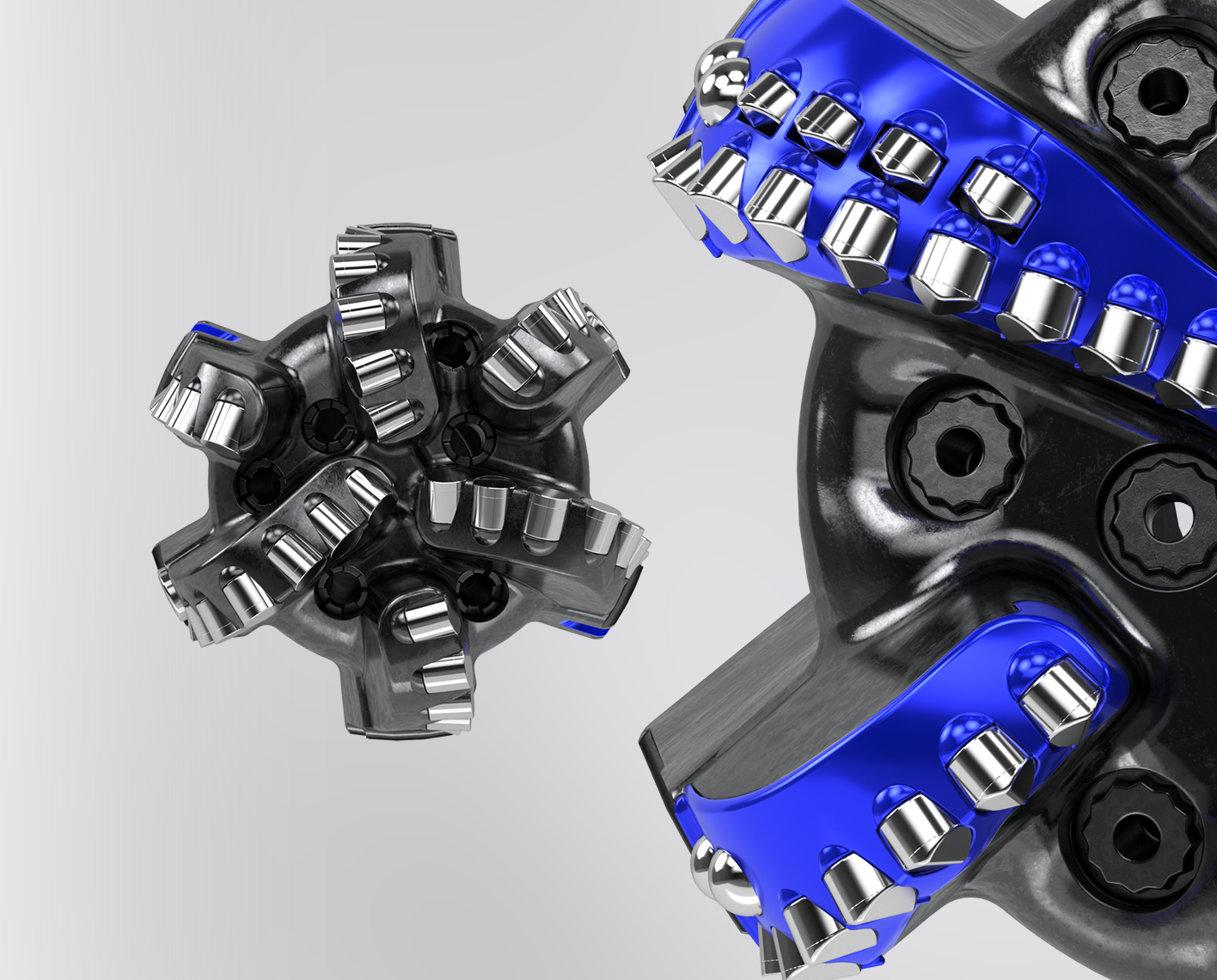

Drill bits

Rock destruction solutions for every drilling application

Better bit performance

What sets our Smith Bits family of bits apart is that we start developing a bit design where the bit meets the rock—the cutting element. It’s very small, but how it interacts with the rock type has really big impact. And this approach is how we are reshaping bit performance with huge leaps in results for oil and gas and geothermal drilling applications.

We advance better bit performance every day because of our continuing work to understand customers' drilling challenges, and answering those challenges with something not quite as small as it seems.

The Smith Bits family of bits is redefining how a bit should interact with the formation—by communicating with our customers and understanding exactly what they need. And it is this customer-centric methodology that continues fueling our record-breaking performance for nearly 20 years in a row. That's what 120 years of experience, know-how, and dedication can bring to the table.

Bit offerings

Specialty Bits

Meet your performance demand needs

PDC Cutters

The ridged cutting elements improve cutting efficiency, enabling our PDC bits to drill with higher ROP.

MegaDiamond PDC Cutters

Premium polycrystalline diamond cutters

SnapScan

Rapid dull grading and drilling record system

Drilling optimization services

OptiWell

Well construction performance service

OptiDrill

Real-time drilling intelligence service

Suppressor dampening tool

Absorb and reduce torsional vibration

Shock Sub

Impact and vibration reduction tool

Drill Bit Design

Optimize your BHA for any application