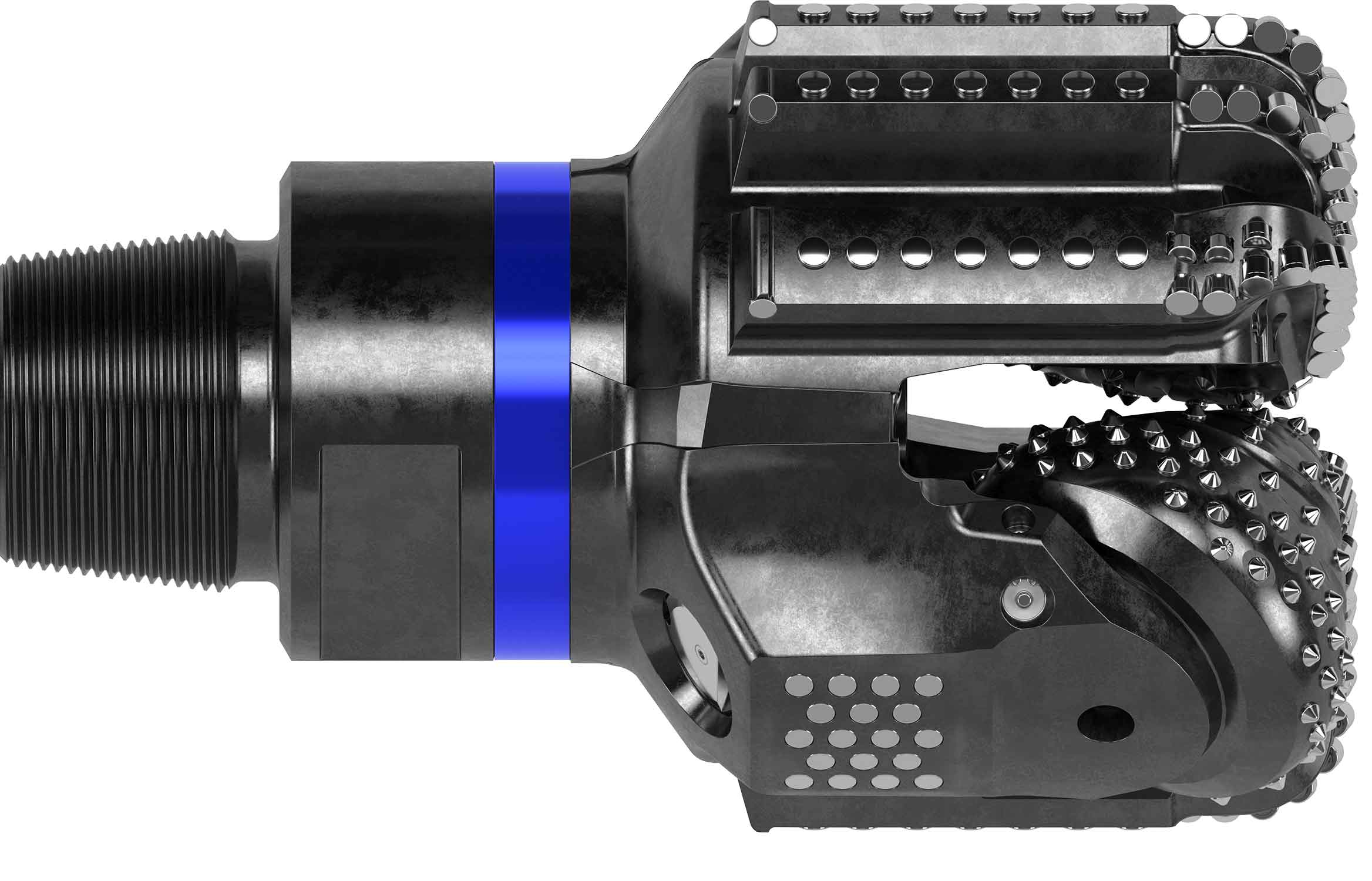

Spyder

Hybrid drill bit

Redefining drilling performance

Spyder™ hybrid drill bit combines the advantages of fixed cutter and roller cone bit designs, improving drilling performance, lowering torque, and expanding its versatility for a wide range of applications. The roller cone cutting action prefractures formations, enabling the fixed cutter structure to shear and remove rock more efficiently. Additionally, the strategic placement of cutting elements on the roller cones reduces torque and enhances bit dynamics. With a fixed cutting structure made from a blend of SLB proprietary premium cutters, the Spyder bit is available in standard sizes ranging from 8½ to 22 in [215.9 to 558.8 mm], making it ideal for oil, gas, and geothermal projects.

- Directional drilling with steerable motor or RSS

- Drilling through lithologies ranging from very soft to hard

- Wells requiring torque management and low levels of stick-slip

- Oil and gas wells

- Geothermal wells

- Better torque management

- Smoother drillbit dynamics

- Improved steerability

- Extended reliability

- Enhanced hydraulics

- Prolonged PDC durability

Bit architecture is built on SLB proven two-cone technology structure

Cones use proprietary conical and Axe™ ridged diamond element shapes developed specifically for hybrid cutting structures

Roller cone and fixed cutter structure work with a synergistic cutting action

Blades use SLB premium cylindrical cutters and 3D shaped cutters