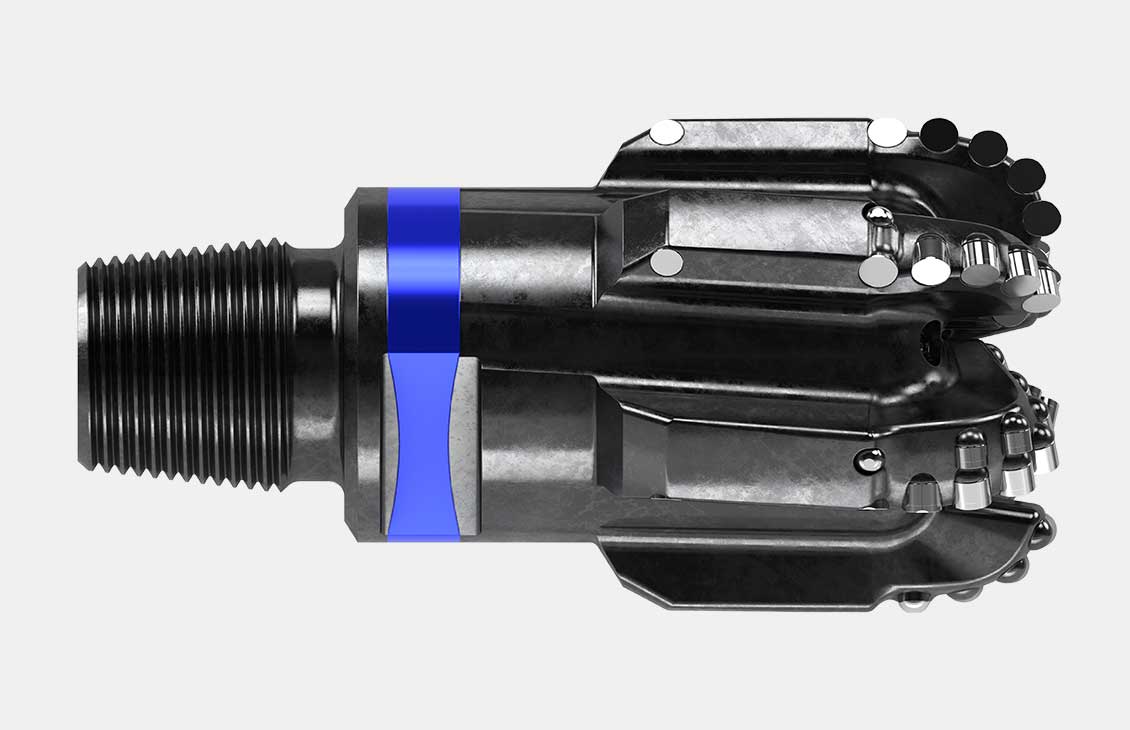

PDC Bits

Get premium performance with superior durability

Workhorse of the oil field

Polycrystalline diamond compact (PDC) bits are the workhorses of the oil field. Features such as cutter types, cutter layout, and blade geometry are continuously being evaluated and improved to deliver value and drive down drilling costs. Certification with the IDEAS integrated dynamic design and analysis platform ensures these bits offer optimal performance.

Additionally, the IDEAS platform and field experience show that a single dynamically stable bit design can provide exceptional performance with a variety of drilling systems, especially in directional drilling. The earlier perception was that each type of rotary steerable system (RSS) or steerable motor BHA required its own bit design with highly specialized directional features. Bits with IDEAS platform certification are stable and produce less torque and stick/slip in transitional drilling. The risk of time-consuming and costly trips due to shock and vibration is greatly reduced.

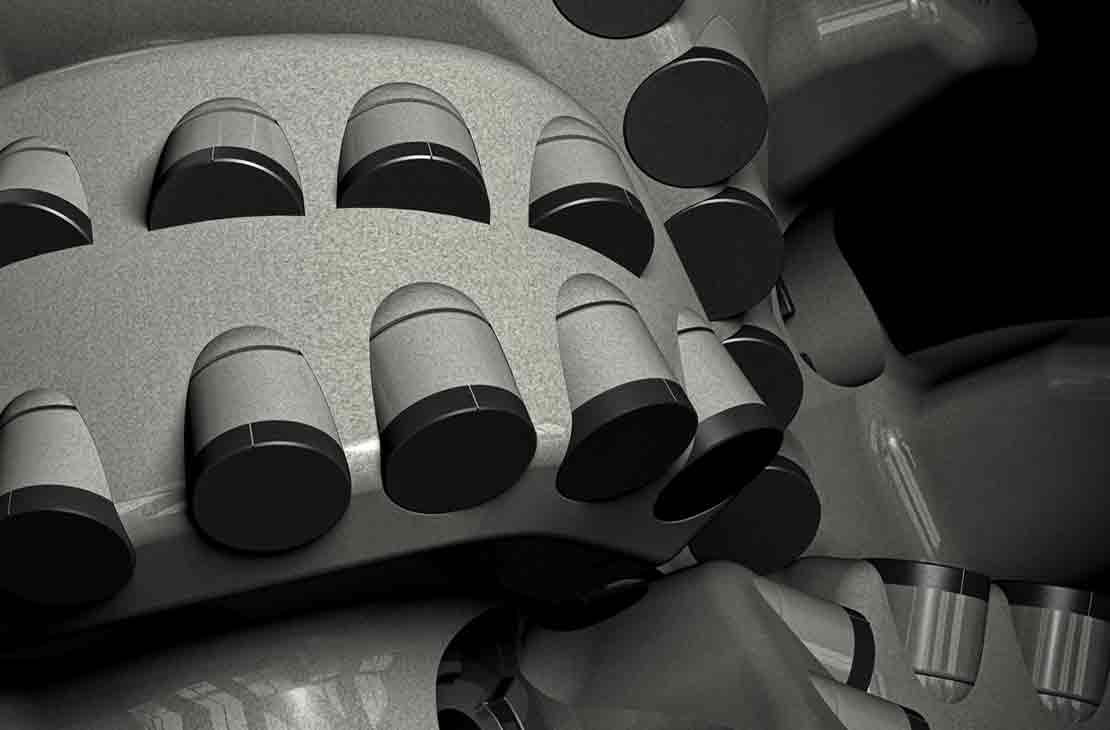

PDC Premium Features

-

CenterFlow

Hydraulically enhanced bitInnovative PDC bit combining Stinger conical diamond element and hydraulic port structure to optimize ROP

-

DualHelix

Multiformation performance bitPDC bit with helical shaped blades delivers efficient cutting performance in soft and hard formations.

-

AccuStrike

Short-makeup drill bitAccuStrike short-makeup drill bit

-

Aegis

3D-printed armorDrill with 400% more erosion resistance and 40% more blade strength than other bit materials.

-

SHARC

High-abrasion-resistance PDC drill bitExtend run life and increase ROP in hard, abrasive formations.

-

Spear

Shale-optimized steel-body PDC drill bitEfficiently drill curve and long lateral sections in shale plays with application-specific PDC bits.

PDC Blade Bits

-

HyperBlade

Hyperbolic diamond element bitIncrease ROP and maintain steerability in plastic formations with the new hyperbolic element bit.

-

AxeBlade

Ridged diamond element bitImprove penetration rates and downhole control with our ridged 3D cutting element bit.

-

StingBlade

Conical diamond element bitSignificantly improve footage and ROP in hard-to-drill formations.

-

EnduroBlade 360

Rolling diamond element bitExtend PDC bit durability with our rolling cutting element technology.

-

StrataBlade

Concave diamond element bitIncrease ROP by up to 35% in medium-strength formations as compared with flat PDC bits.

-

ThermoBlade

Thermal-resistant diamond element bitThermoBlade bit cools HT drilling with increased durability for longer bit life, and overall bit performance