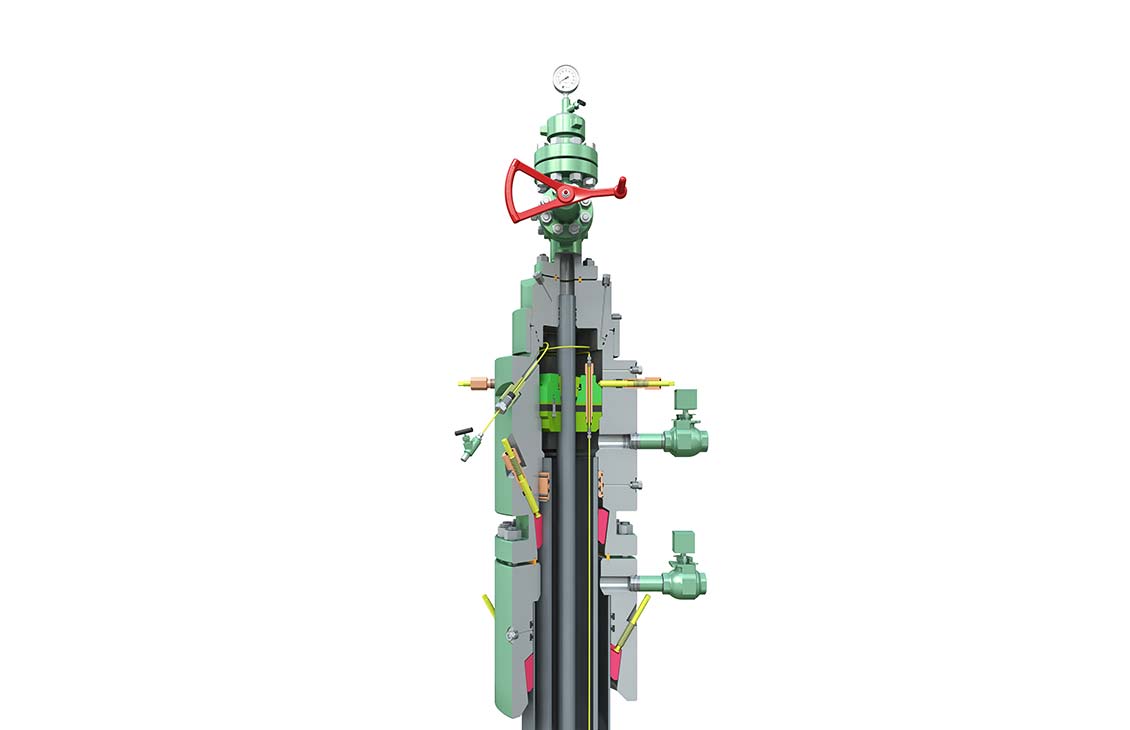

Case Study Cameron Adapt NST™ nested multistage compact wellhead system

An operator saved significant NPT and improved safety with the Cameron Adapt NST compact wellhead system.

Your well performance gateway for any application, any environment, anywhere in the world

It’s not just a wellhead and tree—that’s only the reliable foundation of our life-of-well SLB intelligent surface production system. We’ve introduced new levels of production and injection functionality by bringing together electrification, digitalization, and sensing with our wellhead systems for any application and any environment worldwide. Whether your project is a critical conventional or unconventional oil and gas application; vapor, liquid, or dry geothermal operation; or permanent carbon capture and sequestration (CCS) installation, we’ve seamlessly integrated all system components with edge computing to keep you informed, enable precise remote control, and provide data-backed insight for continuous optimization across the production lifespan of your well.

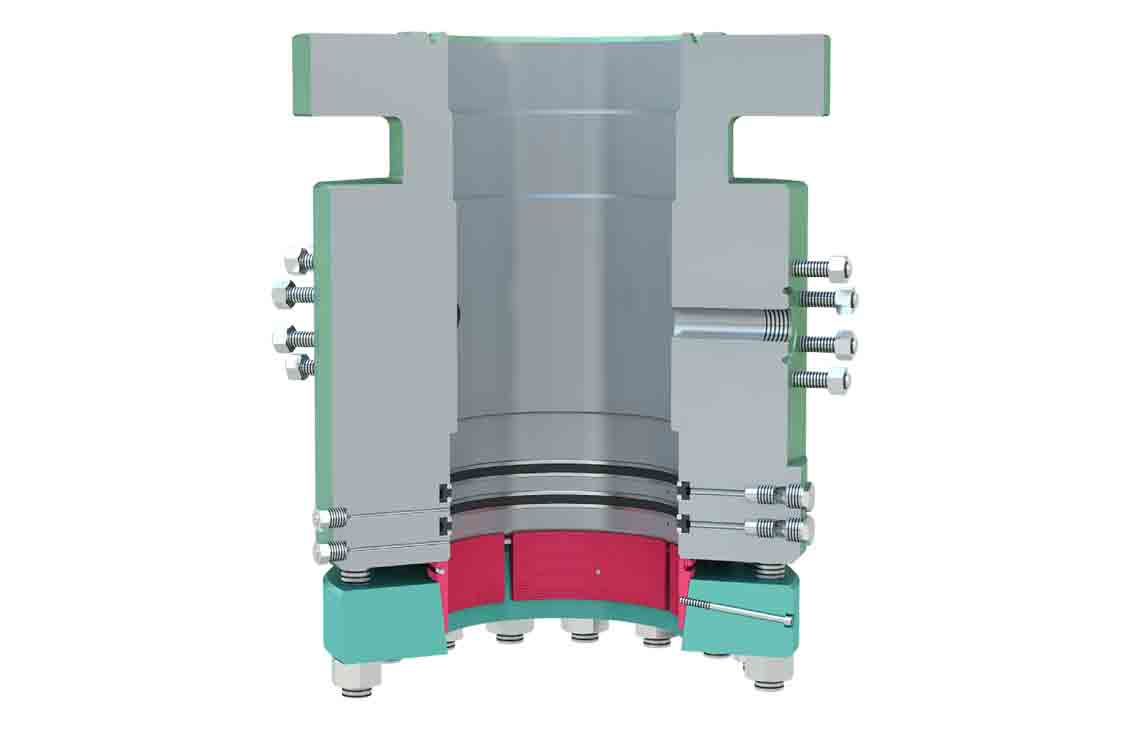

Real-time positive confirmation of properly landed hangers and packoffs on two wells avoids subjective judgments and NPT and minimizes risk.

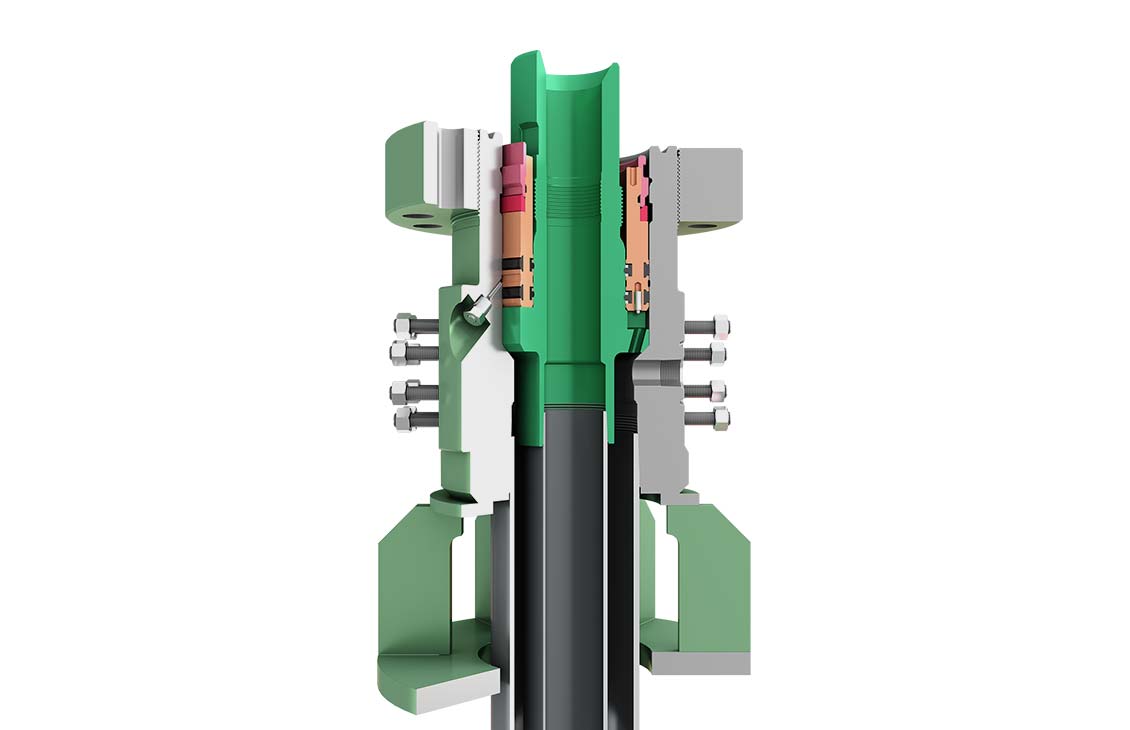

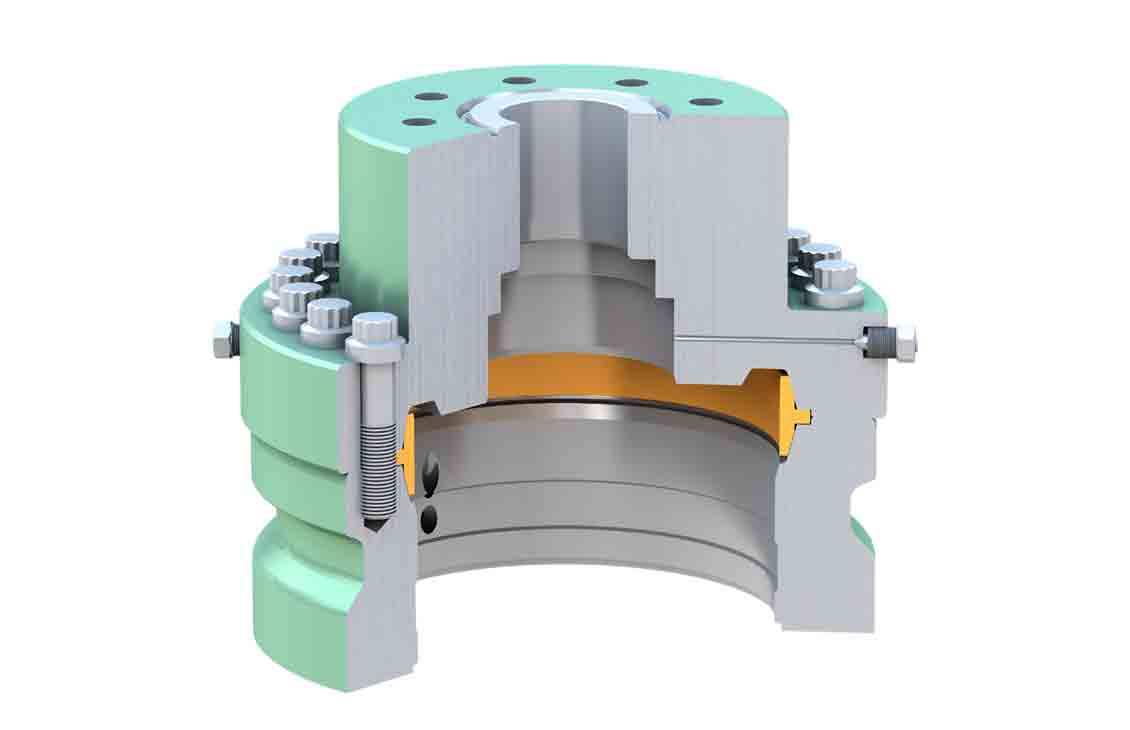

Read tech reportLeverage a wide range of slip-type and mandrel casing hangers and packoffs.

Withstand pressures up to 10,000 psi in a configurable solution. View

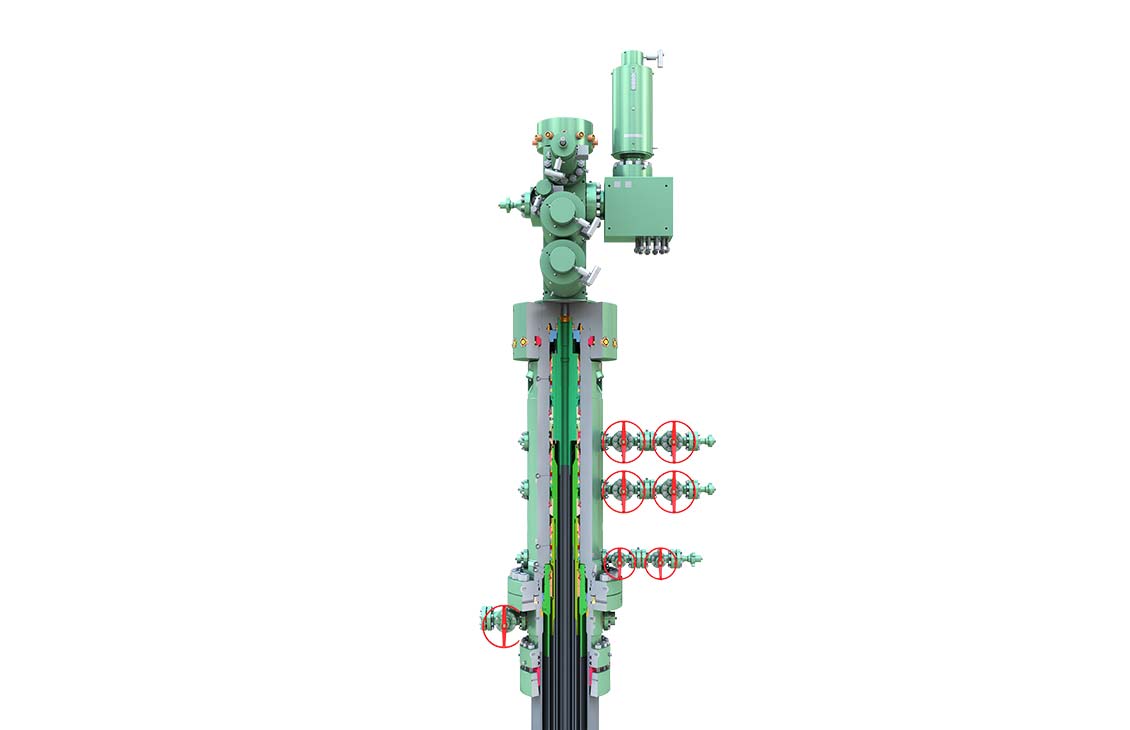

Decrease potential NPT and reduce trips with compact wellhead systems.

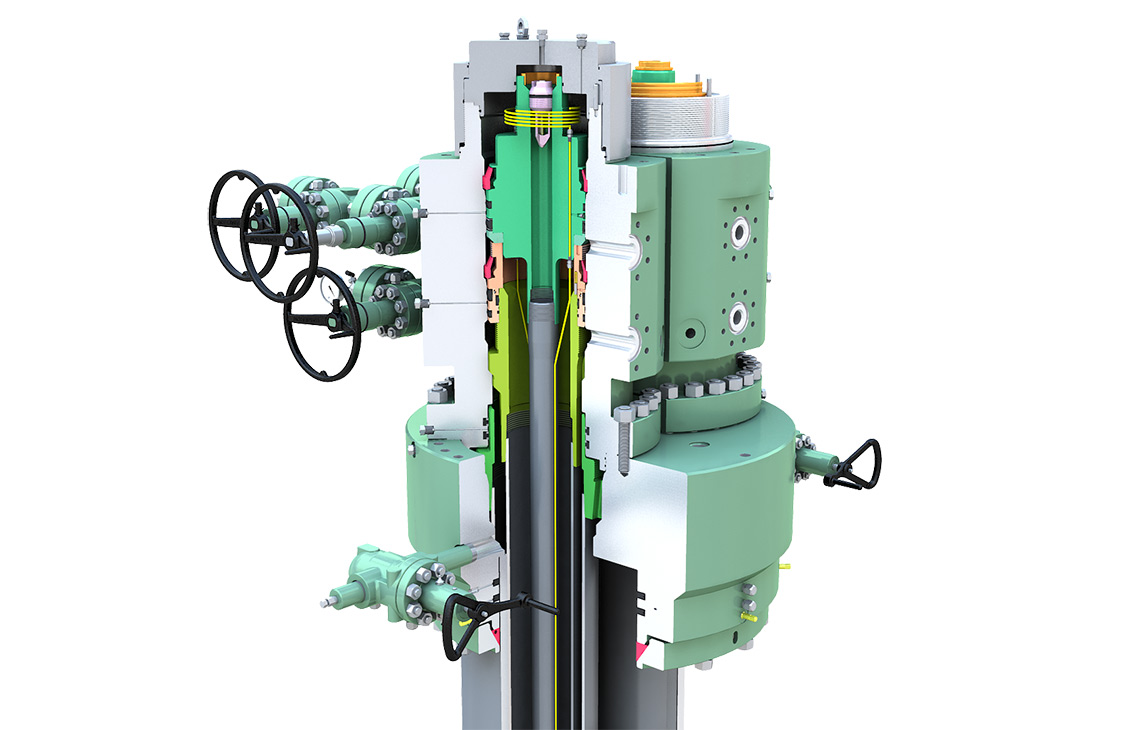

One-piece hanger with gas-tight seals machined onto its surface enables efficient single-trip installation. View

Readily configurable standardized systems for safer, higher-efficiency and -performance drilling operations. View

Achieve configurability, robustness, reliability, extensive service life, and a reduced footprint. View

Work reliably in severe service conditions up to 10,000 psi and steep kickoffs. View

Run the casing head through a diverter with a single-stage wellhead system. View

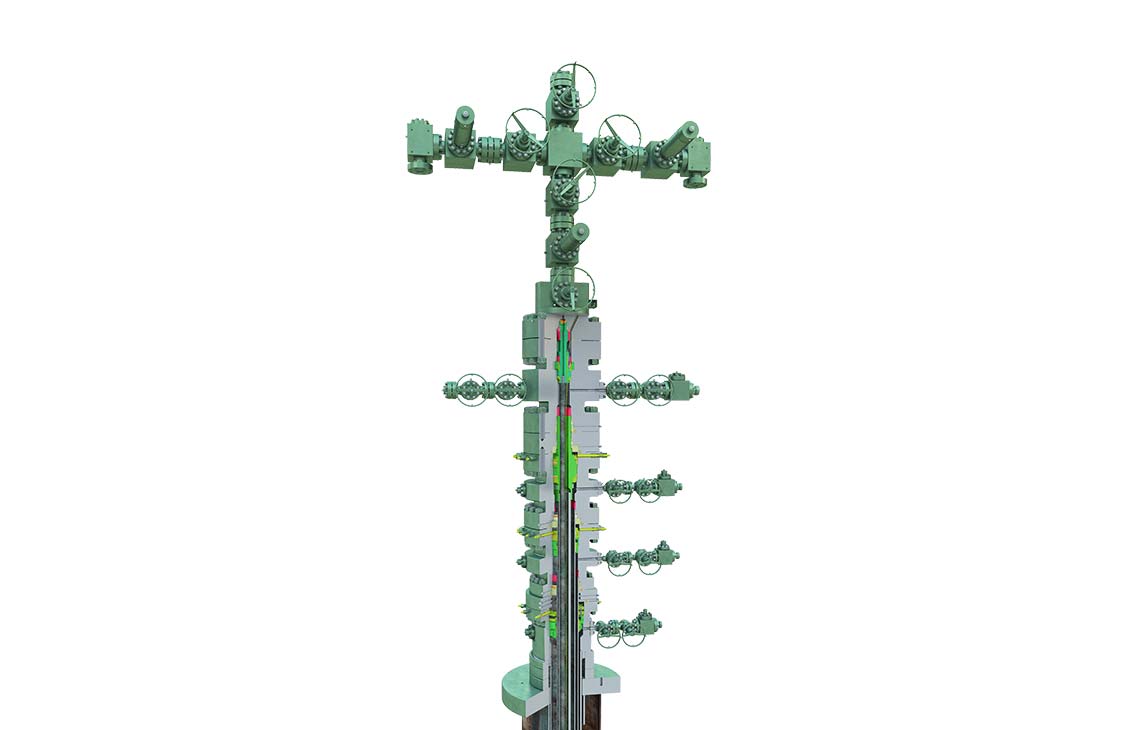

Discover one of the most efficient systems available that can be used either onshore or offshore. View

Drill up to three dual-completion wells from a single slot, and reduce individual well costs and platform size. View

Achieve better performance in HPHT, heavy oil, geothermal, and shallow water environments.

Meet the challenges of high pressure and temperature with a variety of HPHT valves, hangers, and seals. View

Optimize fluid and pressure control for effective heavy oil recovery, including thermal recovery. View

Enhance efficiency in thermally enhanced (steam injection) recovery, waste disposal, and hot-water wells. View

Minimize the amount of dive time required for installation, simplify the diver’s movements, and reduce the number of tools required for installation. View

Save time compared with conventional systems and reduce exposure to hazardous operations. View

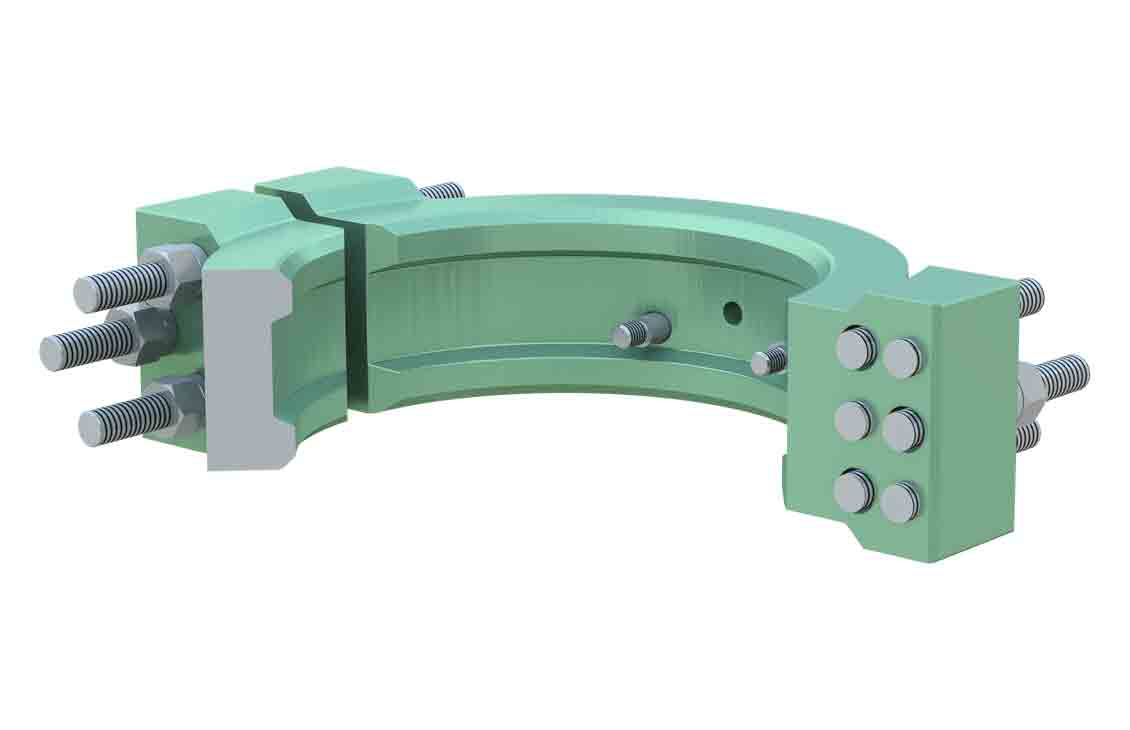

Peruse our selection of wellhead and casing connectors.

Simplify wellhead installation without welding or special tooling. View

Meet the needs of drilling and production with regard to handling safety and makeup time. View

Install safer, faster, and easier with fewer personnel and less force compared with conventional clamps. View

Combine the fast makeup and low-torque requirement of FastLock connectors with the inherent low cost of flange connections. View

Use as an alternative to conventional weld-on or threaded casing connections. View