Anchor–Linear Actuator Tool

ReSOLVE Family instrumented wireline intervention services

Employ controlled high-force linear actuation with high-expansion anchoring capability.

Orchestrated, tractor-powered rotary and milling tool operation

As a component of the ReSOLVE Family instrumented wireline intervention services, the ReSOLVE Family milling tool uses advanced hardware and intelligence to pulverize debris, scale, and other tubular deposits and mill tubing restrictions, plugs, and other completion accessories. No matter your well's condition, both the standard ReSOLVE™ instrumented wireline intervention service and sour-conditions-rated ReSOLVE iX™ intelligent extreme wireline intervention service employ the milling tool to regain well access without introducing potentially formation-damaging fluids. The tool uses a novel PDC bit design. Optimized for maximum rate of penetration (ROP) when milling hard scale buildup, this mill bit achieves the highest rate of scale volume milled within the power limits of electric wireline.

The TuffTRAC™ wireline tractor or TuffTRAC iX™ intelligent extreme wireline tractor is seamlessly integrated to automatically drive the milling tool forward and resist rotation while the tool’s rotating bit engages obstructions. You are fully informed of the tool’s performance status through real-time downhole measurements visualized in an intuitive dashboard.

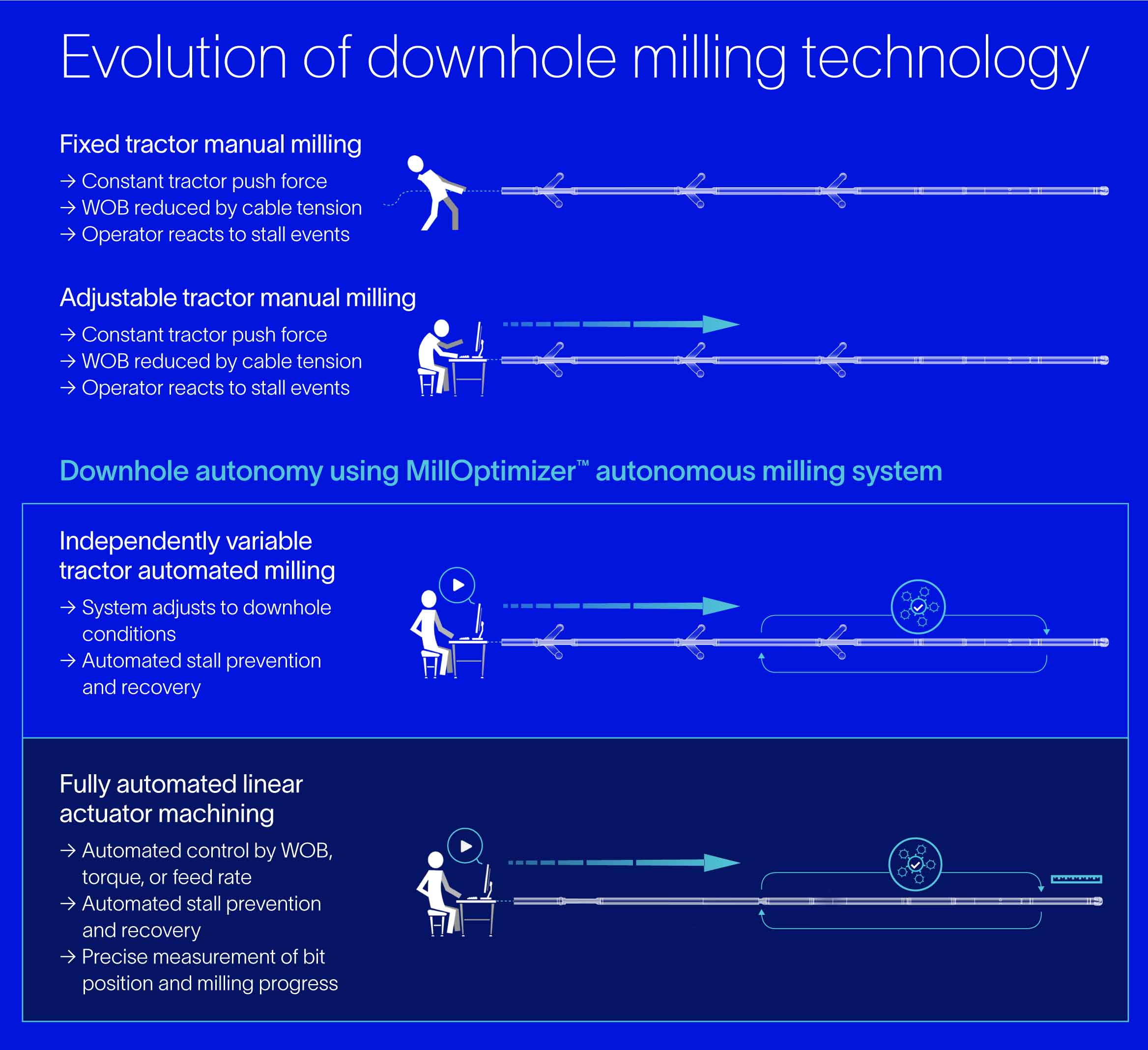

With the autonomous, coordinated control of the MillOptimizer™ autonomous milling system, the tractor and milling tool operate as a single intelligent system to maximize milling efficiency and ensure operation success: The MillOptimizer system, eases dependency on the engineer's intervention compared with existing wireline milling tools that need an experienced engineer to constantly monitor and adjust the milling parameters.

Regain well access without introducing potentially formation-damaging fluids

Access wells with hostile conditions, including sour fluids and high temperatures

Improve operational efficiency with high-speed, maneuverable, bidirectional, intelligently tractor-powered milling

Eliminate surface control latency through downhole autonomous milling operations

| ReSOLVE

Family Milling Tool Specifications |

||

| ReSOLVE iX intelligent extreme wireline intervention service | ReSOLVE instrumented wireline intervention service | |

| Output* | Milling torque,

WOB, milling bit speed (rpm), relative bearing (tool orientation), milling motor temperature, head tension, casing collar locator (CCL) and optional gamma ray, wellbore pressure, wellbore temperature. |

Milling torque, WOB, milling bit

speed (rpm), relative bearing (tool orientation), milling motor temperature, head tension, casing collar locator (CCL) and optional gamma ray, wellbore pressure, wellbore temperature. |

| Milling tool torque* | Adjusted and managed by the MillOptimizer system in real time using WOB generated by the TuffTRAC iX tractor. Max.: 200 lbf.ft [271 N.m]. | Adjusted and managed by the MillOptimizer system in real time using WOB generated by the TuffTRAC tractor. Max.:250 lbf.ft [339 N.m]. |

| Milling bit speed* | Adjusted and updatable in real time in acquisition software. Max.: 600 rpm. | Adjusted and updatable in real time in acquisition software. Max.: 450 rpm. |

| Mud type and weight | All | All |

| Pressure rating | 28,500 psi [196.5 MPa] | 20,000 psi [138 MPa] |

| Temperature range | 32 to 350 degF [0 to 177 degC] | 32 to 302 degF [0 to 150 degC] |

| Restriction, min. | 2.375 in [60.32 mm] | 3.625 in [90.07 mm] |

| Tractoring hole size, max. | 10.5 in [266.7 mm] | 15 in [381 mm] |

| Tool OD* | 2.125 in [53.97 mm] | 3.125 in [79.375 mm] |

| Length, min. | 38.6 ft [11.76 m] | 32.3 ft [9.84 m] |

| Weight* | 354 lbm [160.57 kg] | 657 lbm [298 kg] |

| Tension | 25,000 lbf [111205 N] | 60,000 lbf [266890 N] |

| Special applications | NACE MR0175

compliant for H2O and CO2 resistance. Custom bits on request. Complete range

of standard brushes, hones, and other accessories. Fishing capability: Optional 3⅛- or 2⅛-in [79.38- or 53.97-mm] WIReD™ devices above and below tractors. |

Custom bits on request. Complete

range of standard brushes, hones, and other accessories. Fishing capability: Optional 3⅛- or 2⅛-in [79.38- or 53.97-mm] WIReD™ devices above and below tractors. |

All values are for standard specifications and are subject to

change without notice. A dedicated engineering team is available for

customizing tools to address your challenges.

* Values depend on

configuration.