Video Join SLB at the 2024 SPE/ICoTA Conference & Exhibition | Video

Hear from Matthew Billingham, Technical Director, RP Intervention, to find out what’s in store at ICoTA 2024

Real-time, intelligent control using ReSOLVE Family instrumented wireline intervention services

ReSOLVE Family™ instrumented wireline intervention services expand the operating envelope and ensure more successful well intervention results. ReSOLVE Family services consist of a modular portfolio of intervention tools that deliver real-time monitoring, dynamic tool control, and verified downhole actuation to set new standards for success in well intervention operations.

ReSOLVE Family services are available in two sizes: the 3 1/8-in ReSOLVE™ instrumented wireline intervention service for standard applications and the 2 1/8-in ReSOLVE iX™ intelligent extreme wireline intervention service for extreme conditions of sour, HPHT, and complex completions. Both services can be adapted to meet your objectives and maximize intervention impact.

ReSOLVE Family services include an extensive portfolio of adaptive tools that provide you with more than 200 real-time downhole measurements and diagnostics that can be visualized through a convenient online dashboard. You can now confirm operations as they happen and quickly adjust your actions to address downhole uncertainties without pulling out of hole.

Furthermore, ReSOLVE Family services are engineered with downhole automation to react faster and deliver the best results. There are more than 40 downhole automation sequences, from stroking and opening anchors to milling, managing motor and voltage, and many more.

Reliable, verified shifting in any direction to single or multiple components. View

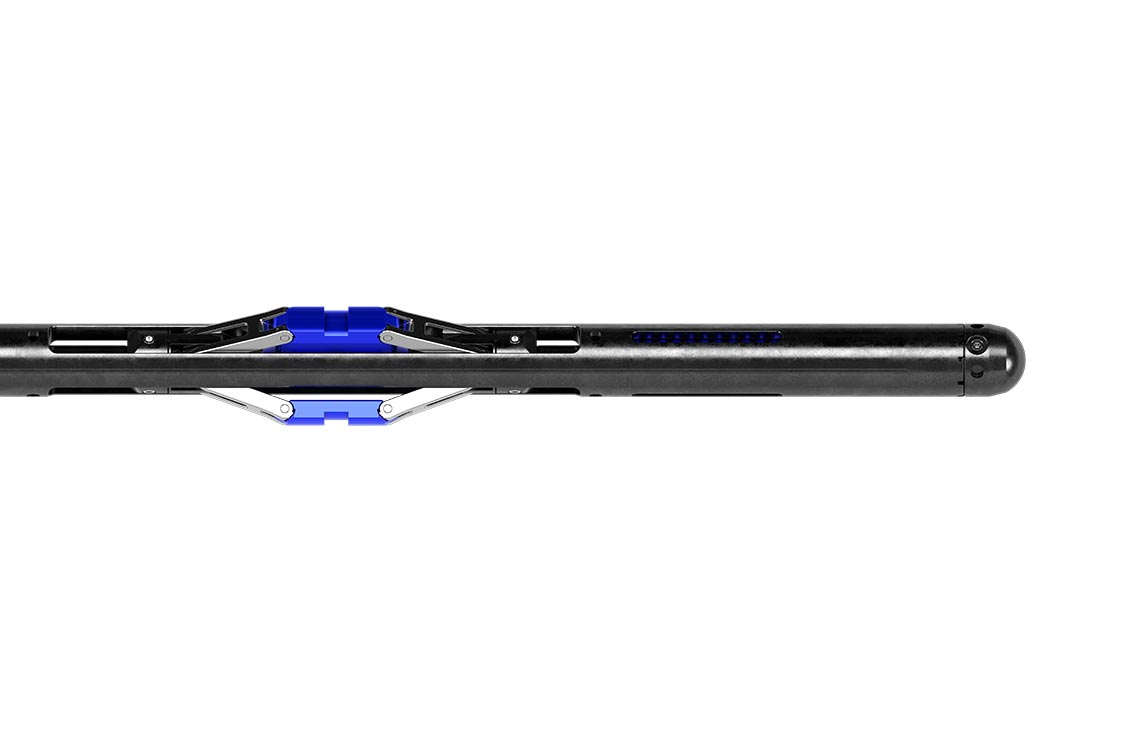

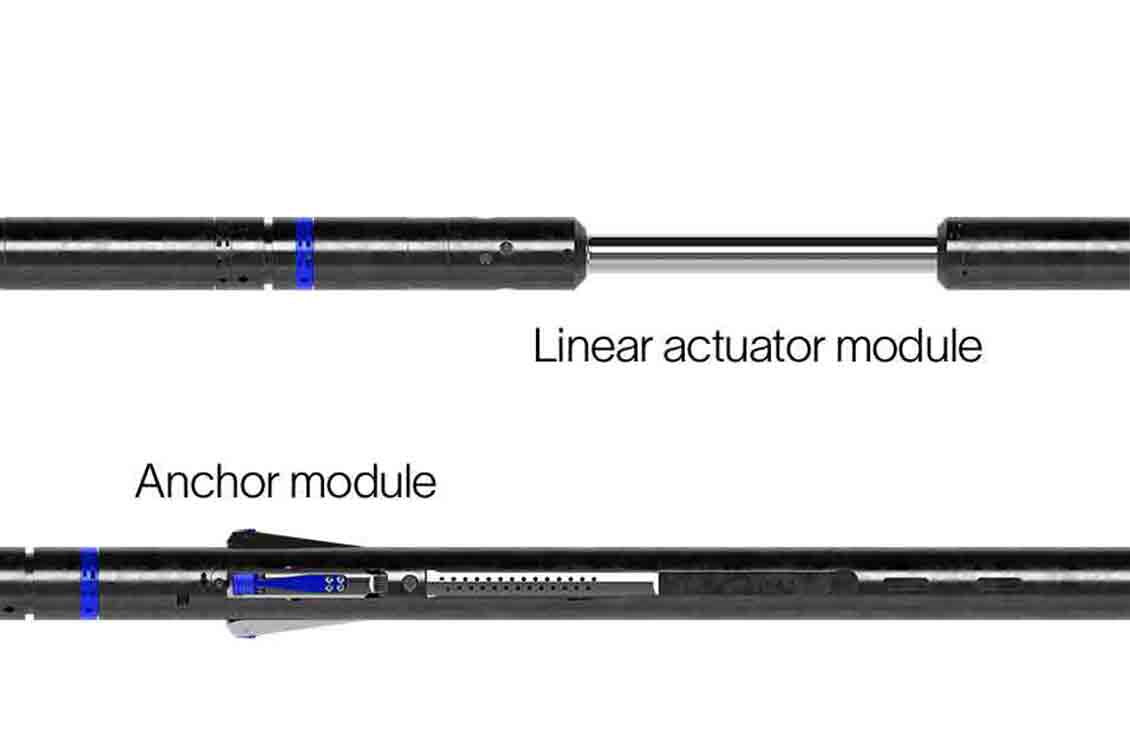

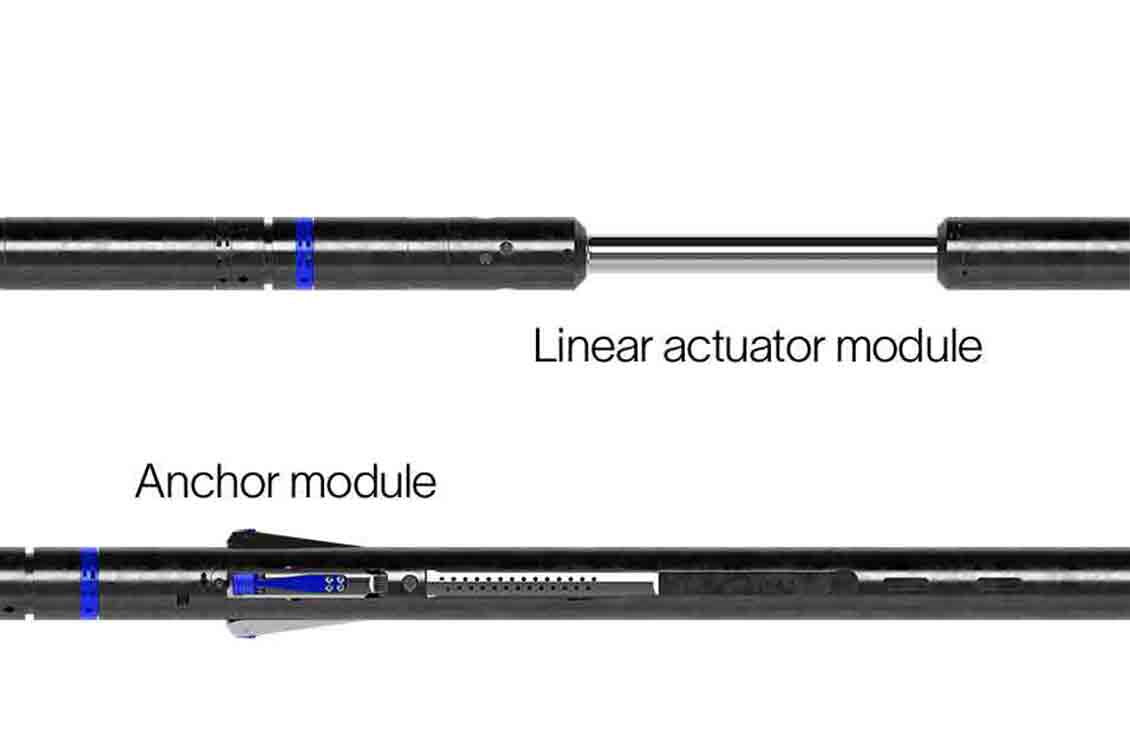

Employ controlled high-force linear actuation with high-expansion anchoring capability. View

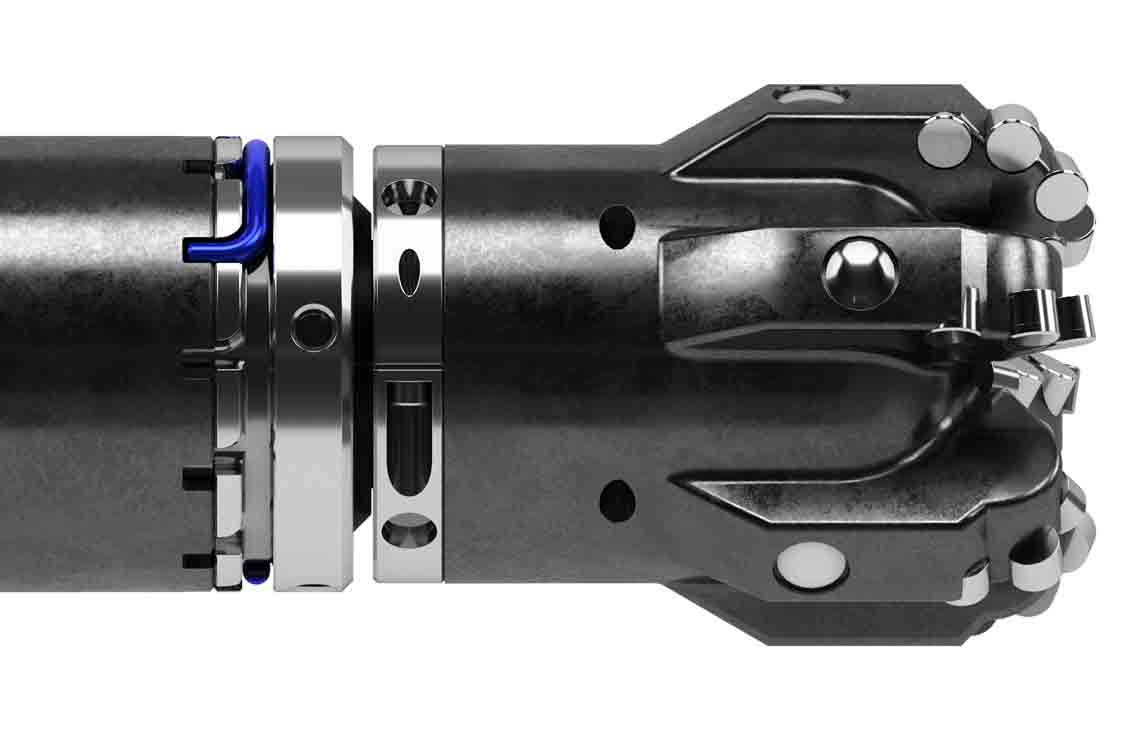

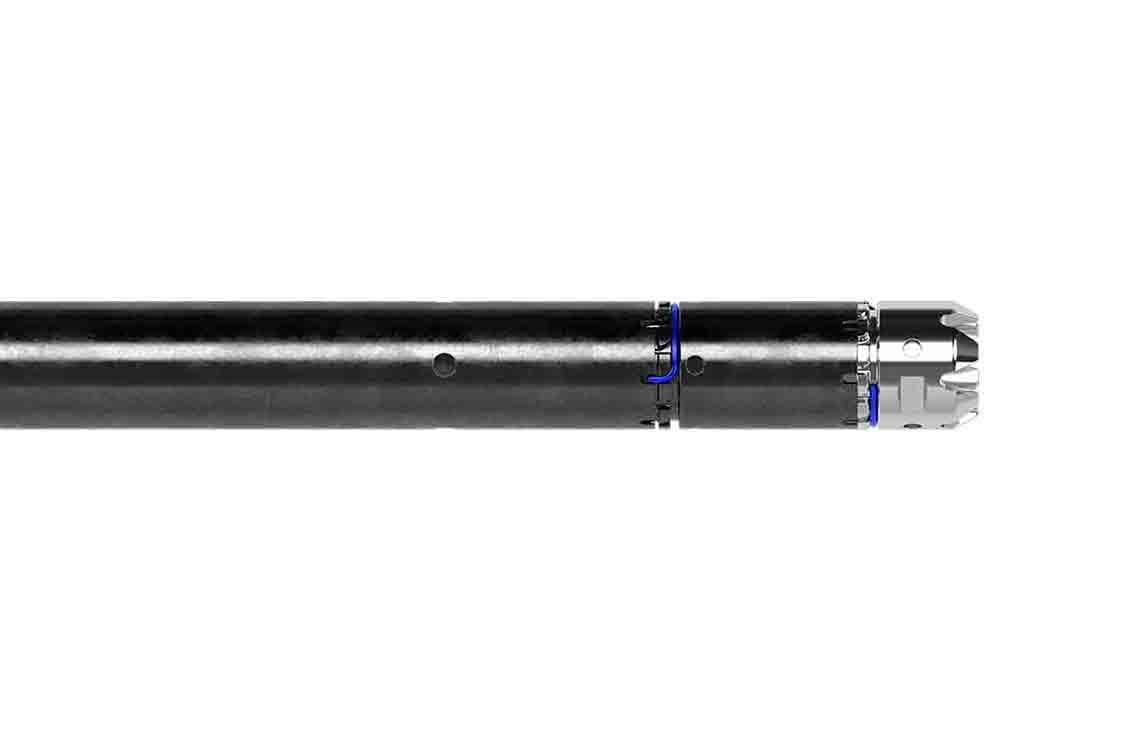

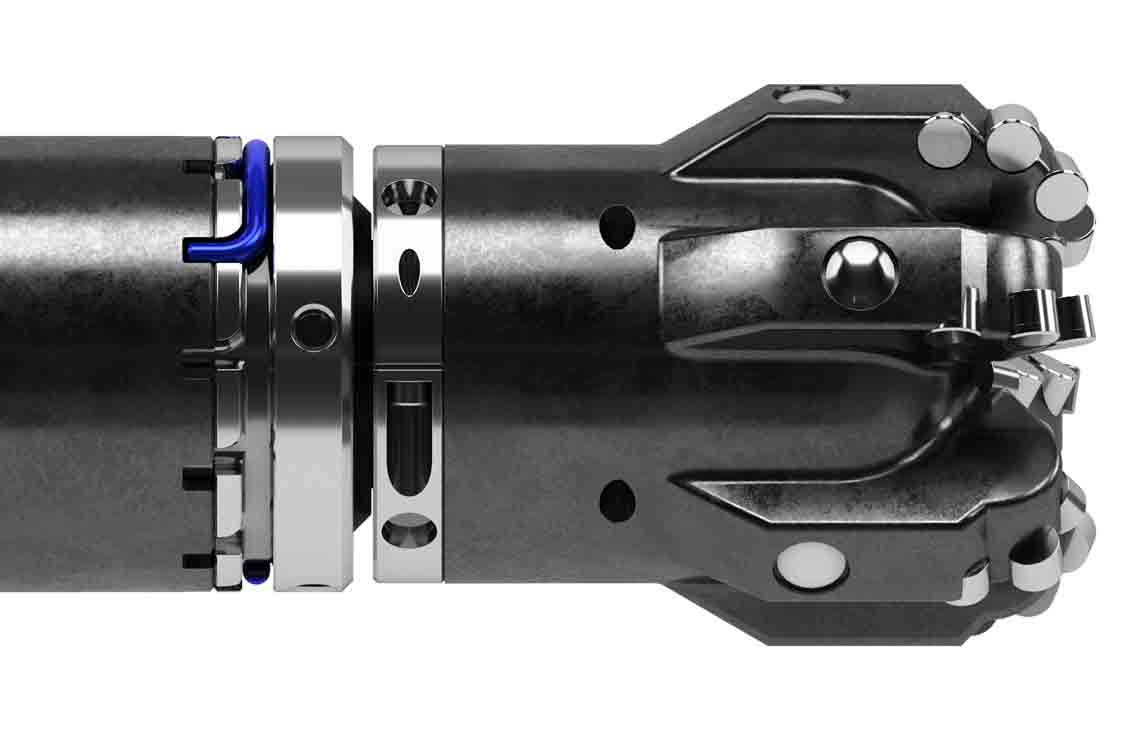

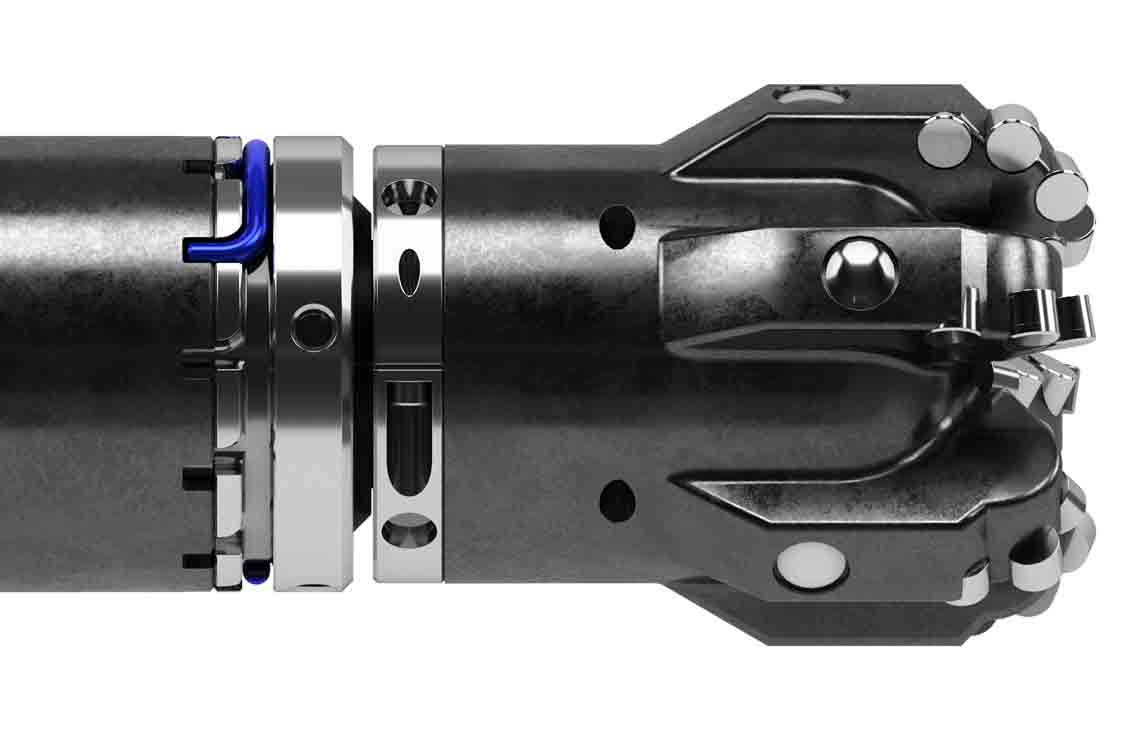

Orchestrated, tractor-powered rotary and milling tool operation. View

Optimize debris collection using wireline deployment, advanced design, and real-time measurements. View

Reliably and securely set plugs and packers without explosives View

Precise machining of completion elements with real-time measurement of milling progress. View

Orchestrated, tractor-powered rotary and milling tool operation. View

Employ controlled high-force linear actuation with high-expansion anchoring capability. View

Orchestrated, tractor-powered rotary and milling tool operation. View

Let us help you customize the best intervention design to meet your challenges.