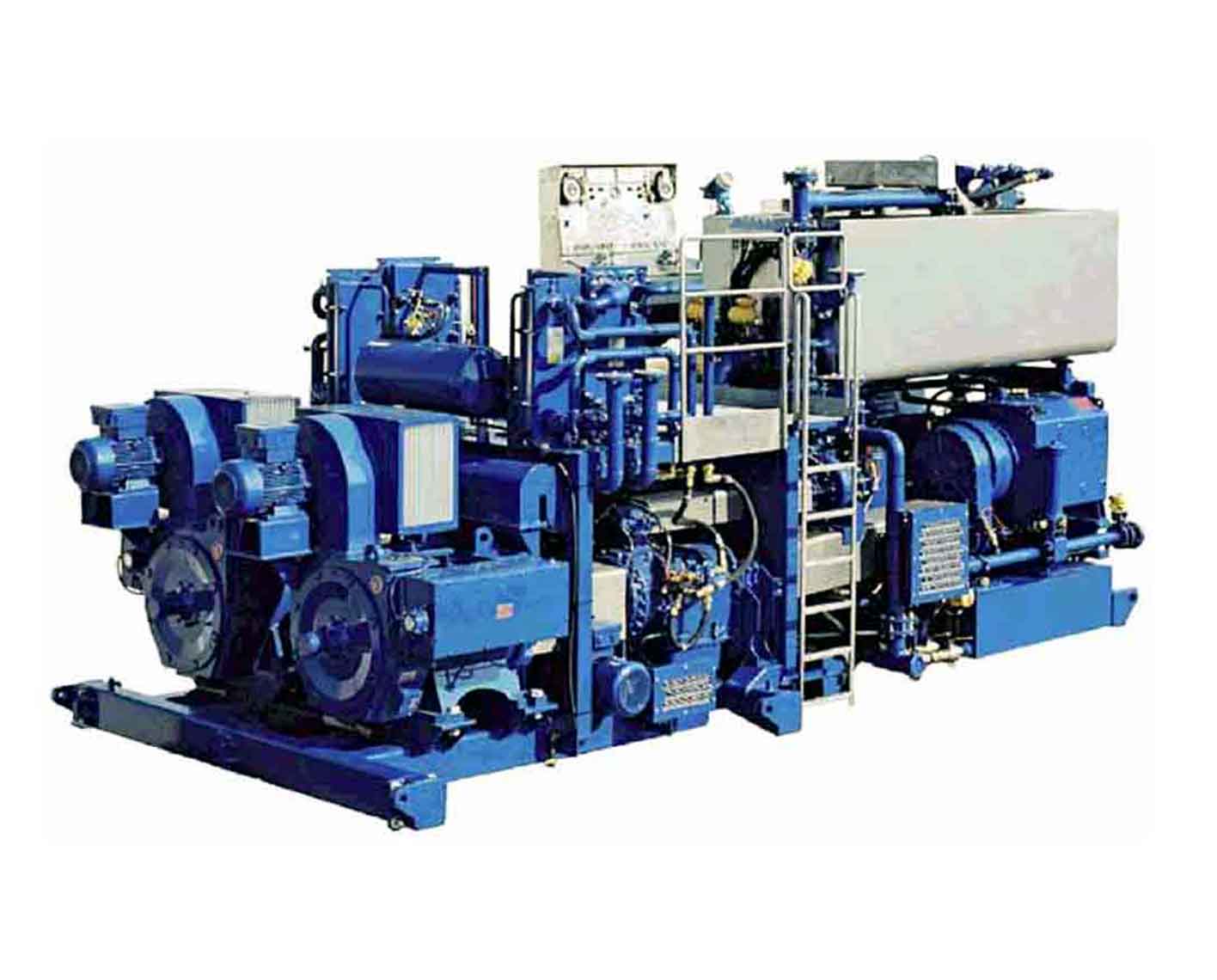

CPS-763

Cement pumping skid

Conventional requirements

Performance expectations are extreme for cementing units onboard ultradeepwater drillships and semisubmersibles. Maximum cement mixing rates and downhole pump rates are critical to improve overall rig efficiency and save valuable time.

CPS-763 skid requirements

The CPS-763 cement pumping skid was designed and built to exceed these extreme requirements. The 1,193-kW [1,600-hhp] unit has the capability to pump 3.8 m3/min [24.4 bbl/min] and can be used at working pressures up to 103 MPa [15,000 psi]. It is optionally equipped with a high-efficiency mixing package of dual Mark III SLURRY CHIEF cement mixers with averaging tanks capable of 3.5-m3/min [22-bbl/min] rates for lead slurries and 2-m3/min [15-bbl/min] rates for standard tail systems.

Two electrically driven 16-m3 [100-bbl] batch mixers can be integrated for spacer or pill mixing isolated from contamination points. A high-rate, process-controlled, direct-injection liquid additive system provides the ability to meter up to six chemicals into the mix-water stream.

Data acquisition and control is handled by two complete systems for redundancy and reliability of automated mixing, solids fraction monitoring, foam process control, and liquid additive system.

Applications

- Deepwater cement slurry mixing and pumping applications

- High-pressure pumping and testing operations

- Precision pumping for integrity tests

Benefits

- Increased mixing rate capability to minimize job time

- Power-take-off- (PTO-) driven cementing pumps for improved reliability and smaller footprint

- Minimal environmental impact because of elimination of need for diesel tank, radiators, and exhaust piping

Features

- Electrically driven 1,193 kW [1,600 hhp]

- 3-in high-pressure lines for accurate high-rate displacement

- Solid fraction monitor to enhance density monitoring