The methane lidar camera is approved by the EPA as an alternative test method and achieved top performance at METEC

In the US, the OOOO family of regulations from the Environmental Protection Agency (EPA) describe what steps oil and gas companies must take to reduce emissions of methane and other pollutants. Those regulations have many requirements—and those requirements have changed many times over the years—but one part that has persisted is the requirement to inspect for leaks. Today, the leak-monitoring requirement applies to fugitive emissions components, covers, and closed vent systems on facilities like well sites, compressor stations, and centralized production facilities that have been constructed, refracked, or otherwise modified in the past 10 years (after September 18, 2015). Similar requirements for all facilities regardless of age are planned to take effect in coming years. The inspections must be performed using one of a limited set of detection technologies that have been approved by the EPA.

Traditionally, those inspections have used manually operated technologies. Although these boots-on-the-ground methods are effective for finding leaks, they have three drawbacks that lead many operators to search for alternatives:

- First, they require extensive manual operation, which increases costs and exposes field crews to windshield time.

- Second, while they can detect fugitive emissions, they often cannot be used for other sources of methane emissions like vents or combustion slip.

- Third, they typically spend only a few seconds inspecting a particular source, leading to inaccurate measurement of emissions that change over time.

Because of those limitations, many operators have begun to use alternative technologies to detect leaks. Until recently, those technologies have been used in addition to manual inspections: while operators deployed new technologies on a voluntary basis, those new technologies were not approved by the EPA, so in order to stay in compliance, those operators had to perform traditional manual inspections even on sites that were monitored using advanced technologies.

Now, EPA has created an alternative test method program whereby advanced methane technologies, if approved by the EPA, can be used instead of—not in addition to—traditional manual inspection. Technologies win approval if they pass a rigorous evaluation process where EPA examines everything from the fundamental physics of the measurement to the results in realistic field tests. In some cases, the technologies that operators had been using on a voluntary basis can now be used for compliance.

In this process, EPA has developed multiple categories of approval. Alternative technologies are approved along three dimensions:

- Geography. Some technologies are approved across all basins in the country, while others are approved only for specific basins.

- Sensitivity. Technologies are approved according to the smallest leak they can reliably detect, ranging from < 1 kg/h to 15 kg/h. Technologies that cannot detect small leaks must compensate by performing inspections more frequently or by supplementing with traditional OGI surveys (although not as frequent OGI surveys as would be required if the alternative technology were not used).

- Resolution. Technologies are approved according to whether they can measure where a leak is coming from exactly or only approximately. Technologies that cannot accurately locate the leak source must be supplemented by an extensive OGI survey—potentially covering the entire facility—after leak detection to identify precisely where the leak is coming from.

The methane lidar camera has now been approved by the EPA as an alternative test method. Importantly, the camera earned the highest level of approval in each category. Regarding geographies, it was approved “broadly across the sector,” meaning it can be used in every basin in the US. Regarding sensitivity, it was approved at all leak resolution thresholds, giving operators flexibility in deployment options. Operators of sites with very low emissions can choose to use a low reporting threshold (down to 1 kg/h), in which case nearly all emissions must be repaired and reported, but inspections do not need to be performed frequently, and routine OGI surveys can be eliminated altogether. Operators of sites with modest emissions can choose to use a high reporting threshold (up to 15 kg/h), in which case small emissions do not need to be repaired and reported, but inspections must occur more frequently and routine OGI surveys may be required. Regarding resolution, it was approved with “component-level resolution,” meaning that when a leak occurs, repair crews can go directly to the leaking component identified by the camera without the need to scan other parts of the facility to determine the source of the leak.

Like all approved technologies, the approval covers not only the hardware but also a workflow describing how the hardware should be deployed. The workflow for using the lidar camera involves the following steps:

- Map the facility and determine where to position the camera using an algorithm written by SLB. For large facilities where one camera cannot cover all regulated components, additional camera(s) are added.

- Install the camera and ensure it passes all the installation QC checks. This step is normally performed by the SLB field crew.

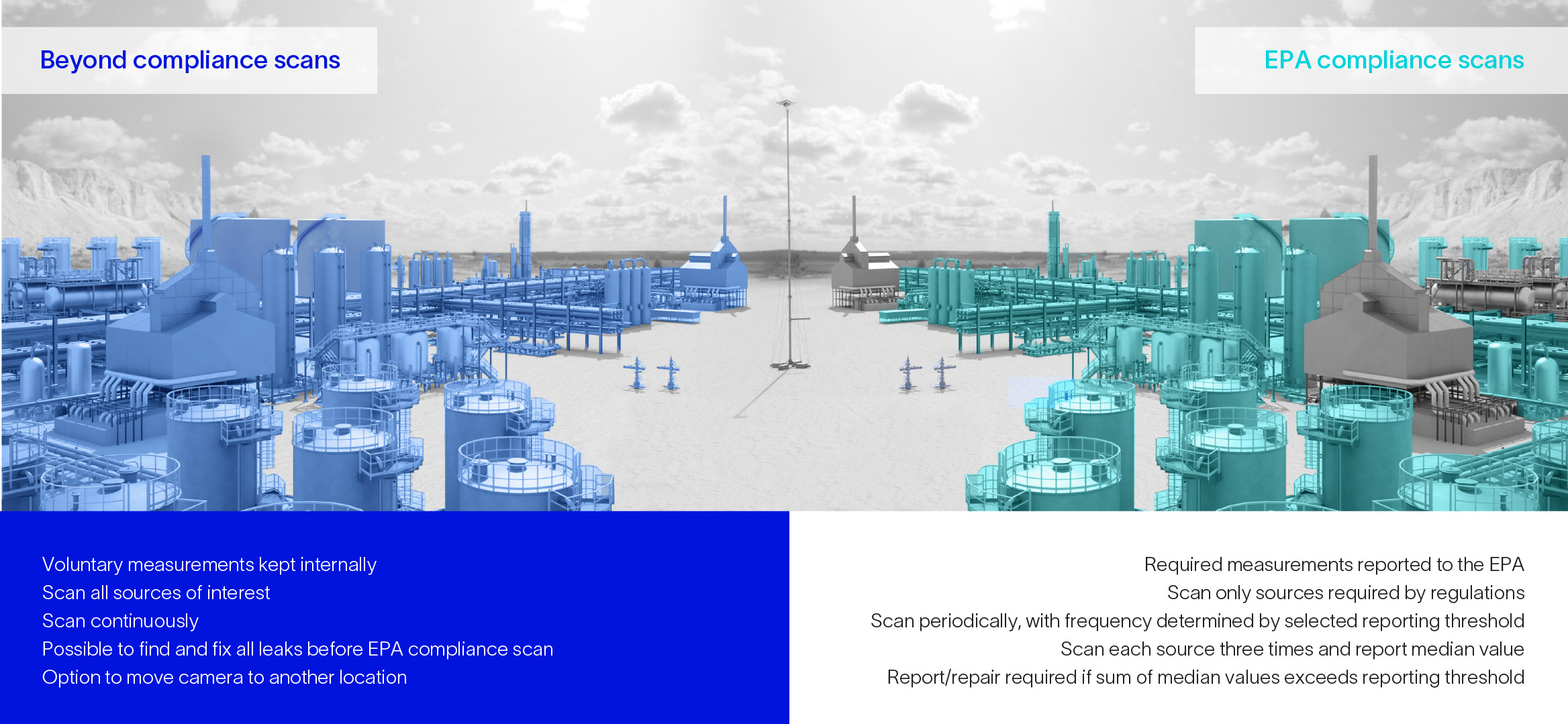

- When EPA inspections are being performed (at a frequency determined by the operator’s selected reporting threshold), the camera measures every regulated component three times and calculates the median value. If the sum of the median values is above the threshold, the leak(s) must be reported and repaired. If there is a highly intermittent leak that is detected in only one of the three scans, no report or repair is required. Nonregulated sources such as permitted vents are not included in the scan plan, so they do not create false alarms reported to the EPA.

- Outside EPA inspections, operators can use the camera as they see fit. Typically, operators will use it for voluntary continuous monitoring, potentially including scans of unregulated sources like permitted vents. EPA encourages operators to run voluntary scans and fix any detected leaks before the EPA scan, in which case operators would not report any leaks to the EPA. Alternatively, operators can move the camera to a different site using a mobile installation.

- All ongoing QC checks are internal to the camera and performed automatically, so there is no need to send personnel to location until the end of the camera’s useful life (10 years), unless one of the QC checks fails or a leak is detected.

As a result of this level of EPA approval, the methane lidar camera provides operators with a single technology that can detect and quantify emissions continuously and nearly 24/7, identify not only fugitives but also nearly all sources of methane emissions, and comply with EPA requirements. The camera replaces all routine manual inspection and obviates the need to send personnel to location unless a problem is confirmed. Unlike other technologies that have been approved by the EPA, the methane lidar camera does not issue false alarms for sites with permitted vents and does not require operators to perform an OGI survey of the entire facility every time a leak occurs.

Complying with the EPA regulations is complicated and becoming more so as more facilities fall under the regulation. Having been approved by the EPA, the methane lidar camera can automate the process, eliminating routine manual inspections and even reducing the number of leaks that must be reported. For operators, EPA compliance just got a little bit simpler.