For oil and gas well casing leak repair, perforation shutoff, tubing repair, and other remedial operations.

Expandable steel patches selectively shut off unwanted CO2 production in four wells

Despite wells with weakened casings and irregular IDs, 12 steel patches were successfully set and expanded across selected perforations, reducing CO2 output from the wells while significantly improving natural gas production rates.

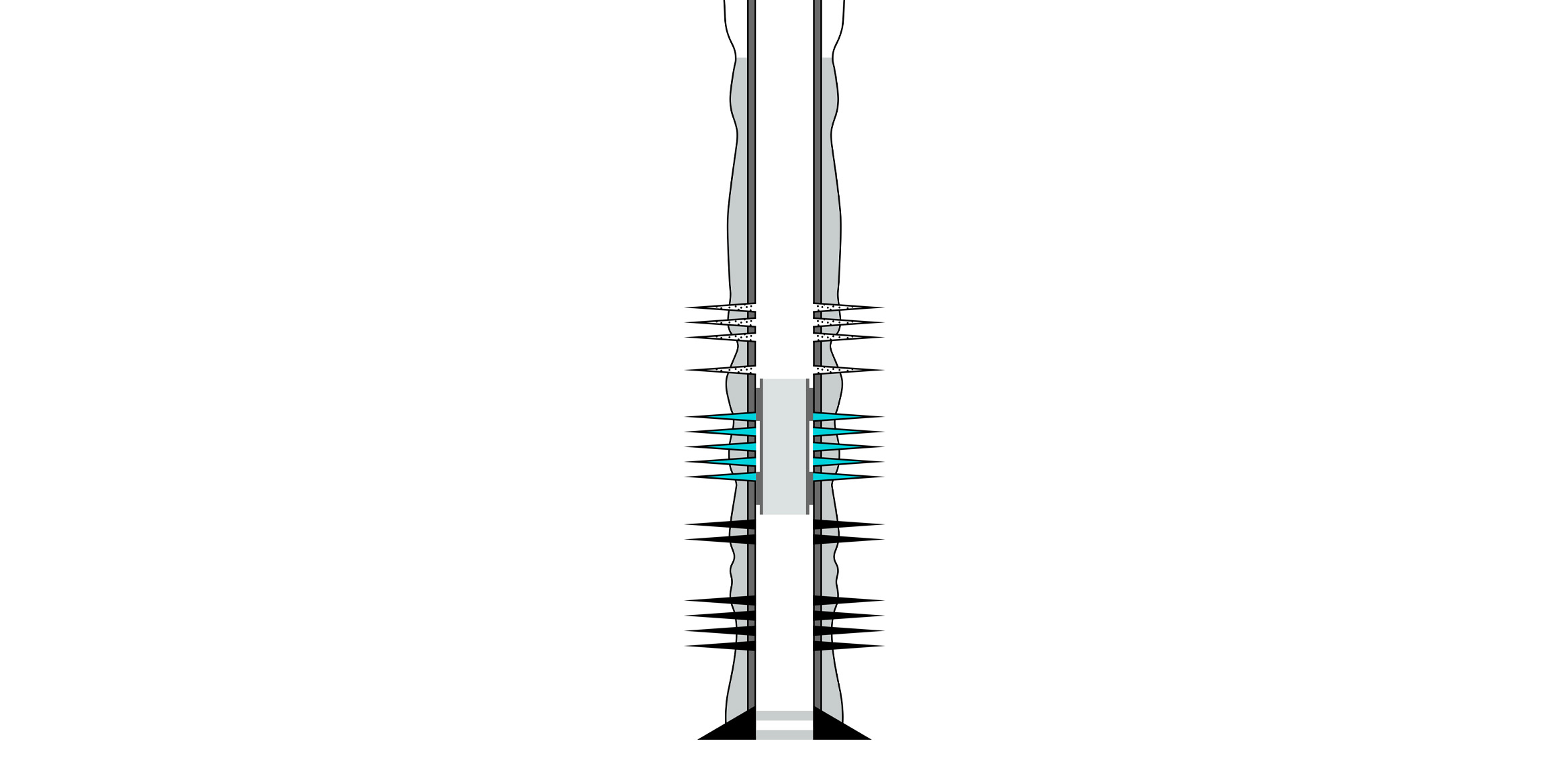

One of the largest operators in Argentina was encountering excessive CO2 production in some of its gas wells. Stainless steel can provide an effective barrier to CO2 migration and has strong resistance to the corrosive impact of this acid gas. Consequently, sealing off the troublesome perforations with expandable steel patches seemed the perfect solution; patch IDs had to be sufficient to allow passage of intervention assemblies in the future. Weakened casings with irregular IDs resulting from the passage of drilling tools ruled out cone-expanded patches offered by some providers.

After an advanced feasibility study, the operator chose SLB patches for gas perforation shutoff in four wells. Using field-proven Saltel Xpandable™ expandable steel technology, these patches are the only solution capable of creating an inner lining that molds to irregular geometries. A total of 12 patches were to be installed, with lengths ranging from 32 to 82 ft [10 to 25 m].

Despite the remoteness of the wells, the operation was completed efficiently, and the patches were installed with 100% success at an average rate of 15 hours per patch. Unwanted CO2 declined noticeably while natural gas production from the four wells improved significantly.