A technique known as “secondary recovery” is commonly used in the oil industry to maintain reservoir pressure and increase hydrocarbon recovery. Nowhere is this more necessary than in mature fields whose “first” recovery methods have begun to dwindle in their returns. One secondary oil recovery method is water injection (i.e., waterflooding), an approach that has become increasingly imperative as the world looks for less drilling and more renewables. Indeed, many countries now have environmental regulations that impose stricter limitations on oilfield development projects than our industry ever saw before.

That said, while waterflooding is increasing in relevance, its traditional manual approach to monitoring is decreasing in sufficiency. These outdated processes are quickly becoming inefficient (they can thank the current pace of digital transformation for that) and fail to provide a value that aligns with more modern, more integrated digital solutions. In other words, it’s high time our industry’s extensive knowledge, expertise, and experience in water injection management is complemented with the innovative digital processes they need to service the future.

What is water injection (or waterflooding) in oil fields?

Waterflooding maintains reservoir pressure and displaces oil toward production wells by injecting water into the reservoir through something called injector wells. This process is critical to ensuring continuous and profitable production from most mature fields, where natural reservoir pressure has declined over time.

The injected water can come from various sources—including produced water from the reservoir, aquifers, surface water sources, or even seawater—but its quality is critical. Impurities (e.g., suspended solids, bacteria, and dissolved particles) can cause scaling and formation damage in the reservoir. And that’s not the only inefficiency caused by a lack of control of the injection process. There’s also the risk of excess or insufficient reservoir pressure, or even water loss due to leaks or injection into nonproductive zones.

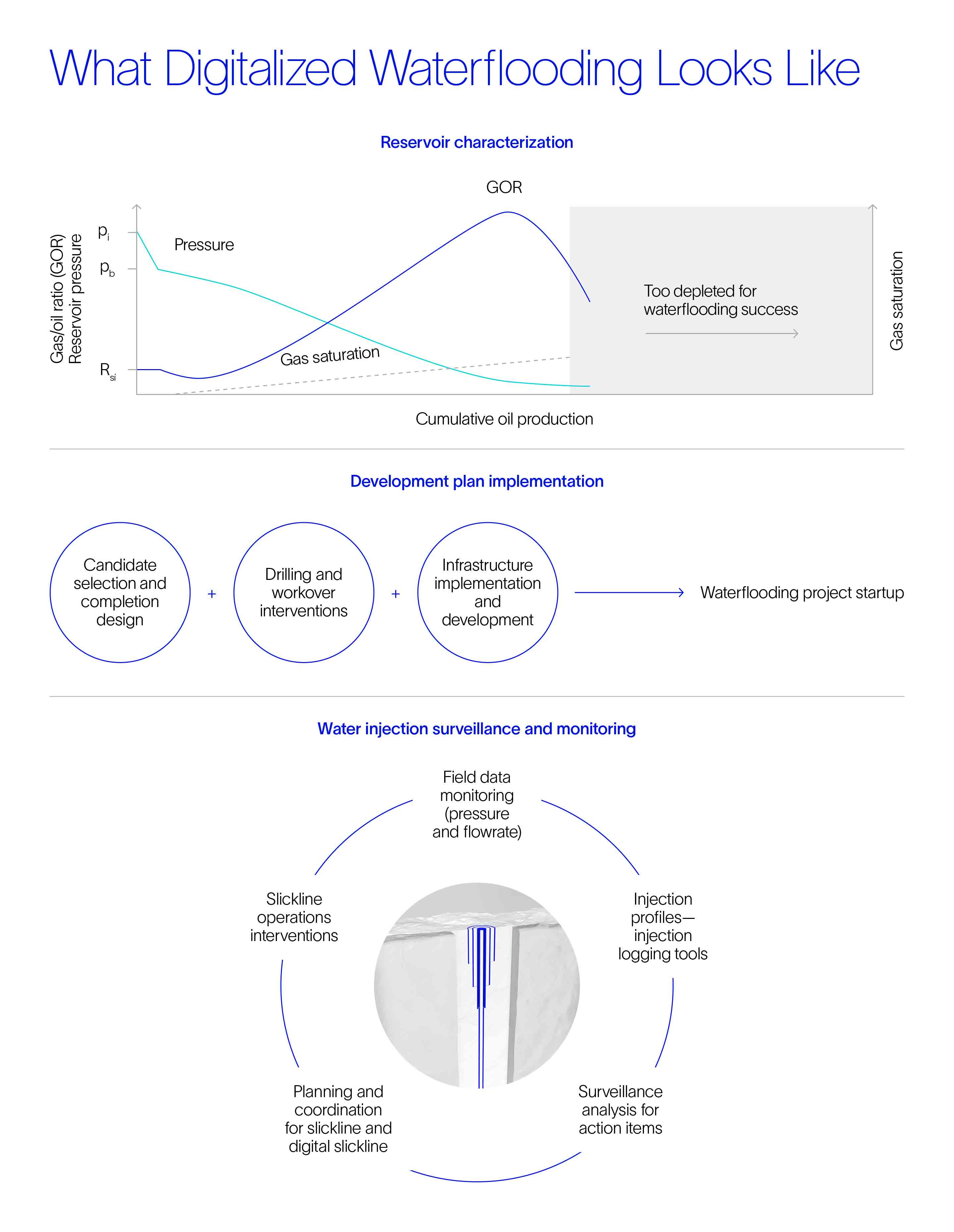

This is where digitalization comes in. It can overcome these challenges and, in many cases, avoid them all together by leveraging sensors, artificial intelligence (AI), and automation, thereby optimizing the water injection process and reducing operational costs. How? By touching three important areas in the recovery process:

- Reservoir characterization

- Development plan implementation

- Water injection surveillance and monitoring.

Digitalizing the water injection process

Conventional operations manage water injection with manually collected data or basic monitoring systems. This leads to delays in problem detection, water disposal, and low production efficiency. The most common hurdles include

- Lack of real-time monitoring, making early failure detection difficult.

- Loss of injection efficiency, due to the absence of predictive models that automatically adjust water volumes to changing reservoir needs.

- High operational and maintenance costs, resulting from an overreliance on manual interventions and the lack of automation.

- Undesirable environmental impact, linked to excessive water use and waste generation.

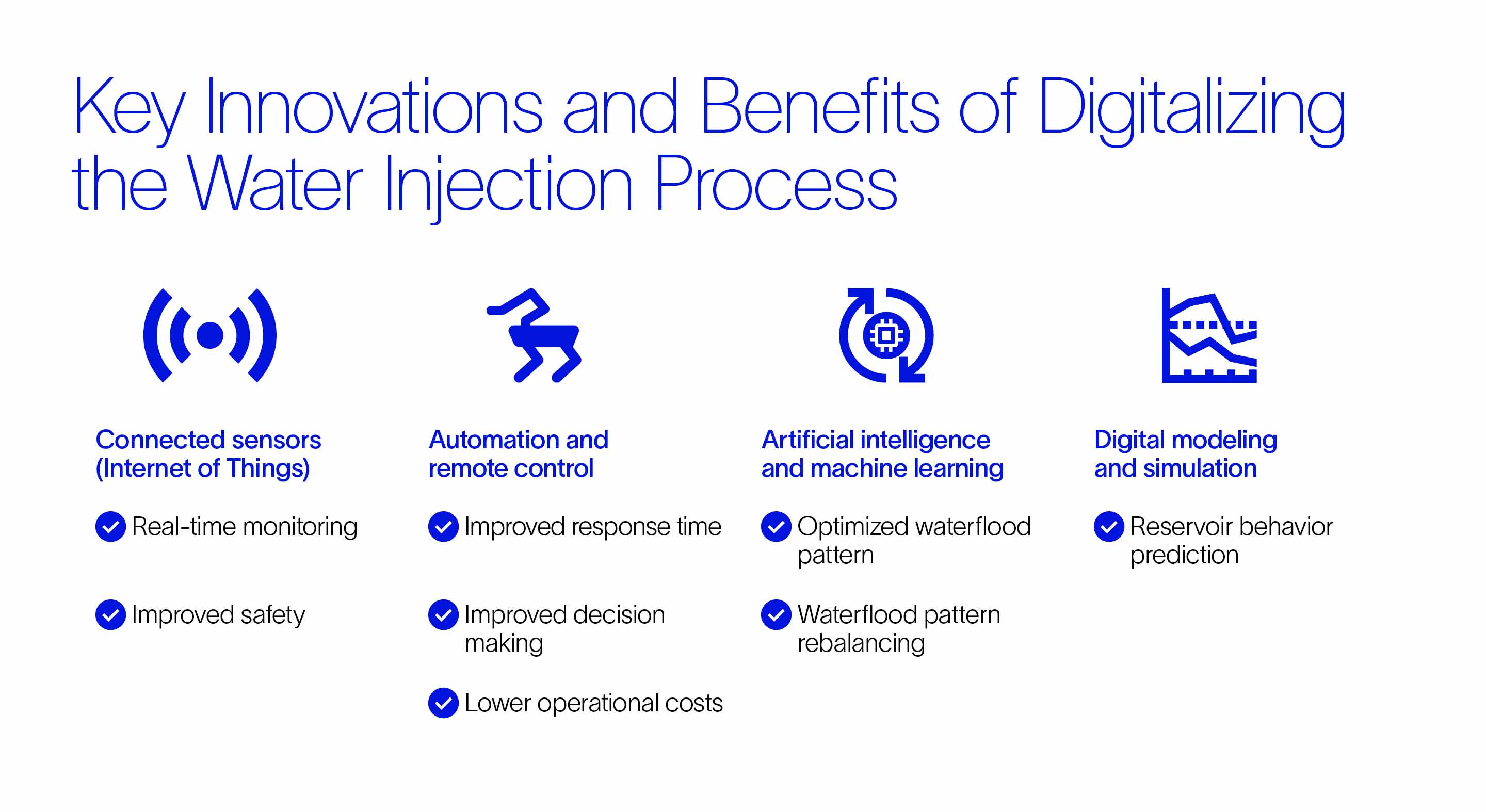

So, what are some of the innovations, some of the advanced technologies, that can digitalize water injection to enhance efficiency, safety, and environmental sustainability all at once? Here are the ones that immediately come to mind—the ones that should be considered requirements at this point.

IoT sensors and real-time monitoring

Internet of Things (IoT) sensors continuously collect data on key variables, such as reservoir pressure, injection rates, temperature, and water salinity. These devices, connected to cloud-based platforms, reduce operational failure risks by enabling real-time monitoring and rapid anomaly detection.

How it might be applied: If a sensor detects a drop in injection pressure, the system can automatically adjust the pump rate or generate an alert for inspection.

Automation and remote control

Automated control systems dynamically adjust injection rates according to reservoir conditions. With remote operation capabilities, operators can manage multiple wells from a central location, which reduces the need for workers on site and enhances their safety.

How it might be applied: If a well experiences a pressure drop, the system can automatically increase injection in a nearby well to balance the injection pattern.

Artificial intelligence and machine learning

AI algorithms analyze large volumes of operational data to improve the volumetric balance of water injection patterns. This facilitates the kind of rapid, data-driven decision making that improves efficiency and reduces resource waste.

How it might be applied: An AI-powered system can analyze reservoir behavior and suggest injection adjustments to optimize oil recovery, all without constant human intervention.

Digital modeling and simulation

Digital twins can simulate reservoir behavior and predict its response to different injection strategies. These simulations help optimize water distribution within the reservoir, thereby maximizing oil recovery while minimizing costly interventions.

How it might be applied: Before increasing injection rates in a specific zone, a digital twin can simulate the impact on reservoir pressure and production for better, data-backed decision making.

Reaping the benefits of digitalized water injection

Implementing digital tech throughout the water injection process provides operators with numerous advantages:

- Optimized water usage—Enhanced process efficiency reduces water waste.

- Lower operational costs—Early fault detection and optimized injection reduce maintenance and production costs.

- Improved safety—Remote monitoring and automation minimize workers’ exposure to hazardous environments.

- Reduced environmental impact—Efficient water use and lower waste generation contribute to sustainability.

That said, considerations must be taken. These include the availability of a water source, characteristics of the reservoir, mechanical integrity of both production and injection wells, surface facilities, and fluid disposition. The good news is that there’s generally easy access to a water source, it’s cheaper to handle water (as opposed to other types of fluids), the injection process is relatively simple from an operational point of view, and the water has a high displacement efficiency.

The digitalization of water injection in oil fields represents a major advancement for the industry, enabling safer, more efficient, and more sustainable process management. By integrating IoT sensors, AI, digital twins, and automation, operators can optimize their oil recovery, cut their costs, and minimize their unwanted environmental impact. Implementing these technologies may require an initial investment and workforce training, but my experience tells me that the long-term benefits in operational efficiency and profitability make it all worth it. After all, digital transformation remains a priority for the future of the hydrocarbon industry.