Pipesim steady-state multiphase flow simulator

Production optimization over the complete lifecycle

The new generation in multiphase flow simulation to overcome fluid flow challenges and optimize production.

In gas lift applications, the injected gas reduces the hydrostatic pressure of the fluid column and reduces the density of the hydrocarbons to enable flow to surface. If too much gas is injected, operating costs increase. When too little gas is injected, production suffers. With conventional technology, flow rate changes in one well also affect rates in other wells, making it difficult to optimize all of the wells in a system.

Modum Gas™ gas metering control system manages gas injection rates into a well, maintaining your ideal flow rate with self-regulation. This reduces gas lift costs and enables production optimization. The technology also enables you to make remote adjustments to accommodate changing well and system conditions.

0.01 to 10 MMcf/d [283 to 283,000 m3/d]

up to 10,000 psi [69 MPa]

The self-contained device requires no additional modification on the flowline, which limits installation costs and footprint. The flow controller can be connected to existing customer SCADA system or an SLB AgoraGateway™ ruggedized edge computing device to enable remote monitoring.

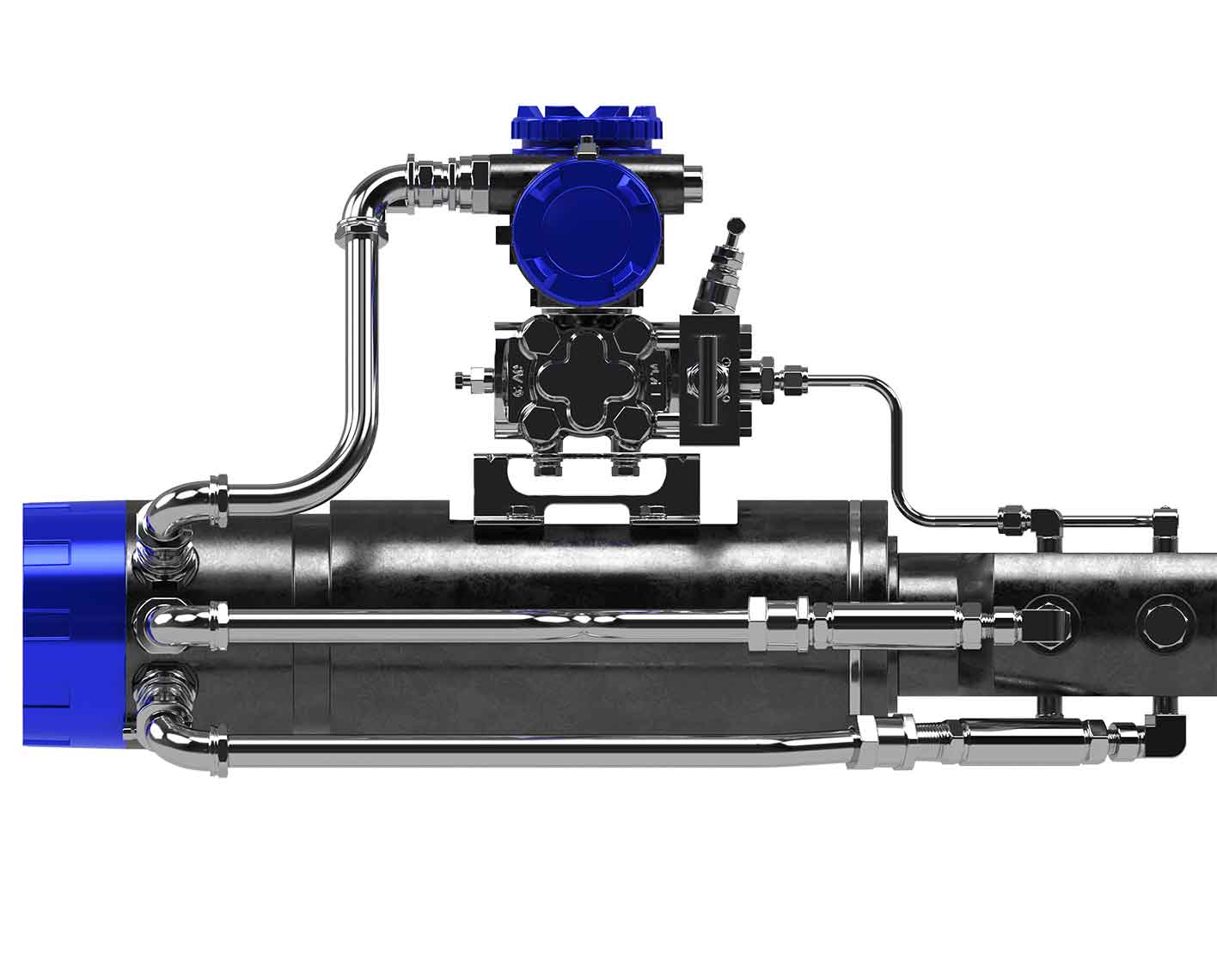

Modum Gas system is a valve integrating sensors, needle valve assembly, flow controller, stepper motor, and LCD. The sensors measure temperature, inlet and outlet pressure, and differential pressure (DP). Based on field-proven subsea chemical injection metering technology, Modum Gas system requires no modification to your flowline, which limits installation costs and footprint.

The flow controller uses the pressure and temperature data and the stepper motor position to calculate the flow rate in real time. If the rate falls outside of a drift range that you select, the integrated needle valve is modulated to maintain the programmed flow rate target. Needle sizes can be optimized to suit applications from 0.01 to 10 MMcf/d [283 to 283,000 m3/d].