Zero-Flaring Well Test and Cleanup

Lower emissions. Greater returns.

Achieve flare-free operations using fit-for-purpose technologies and techniques

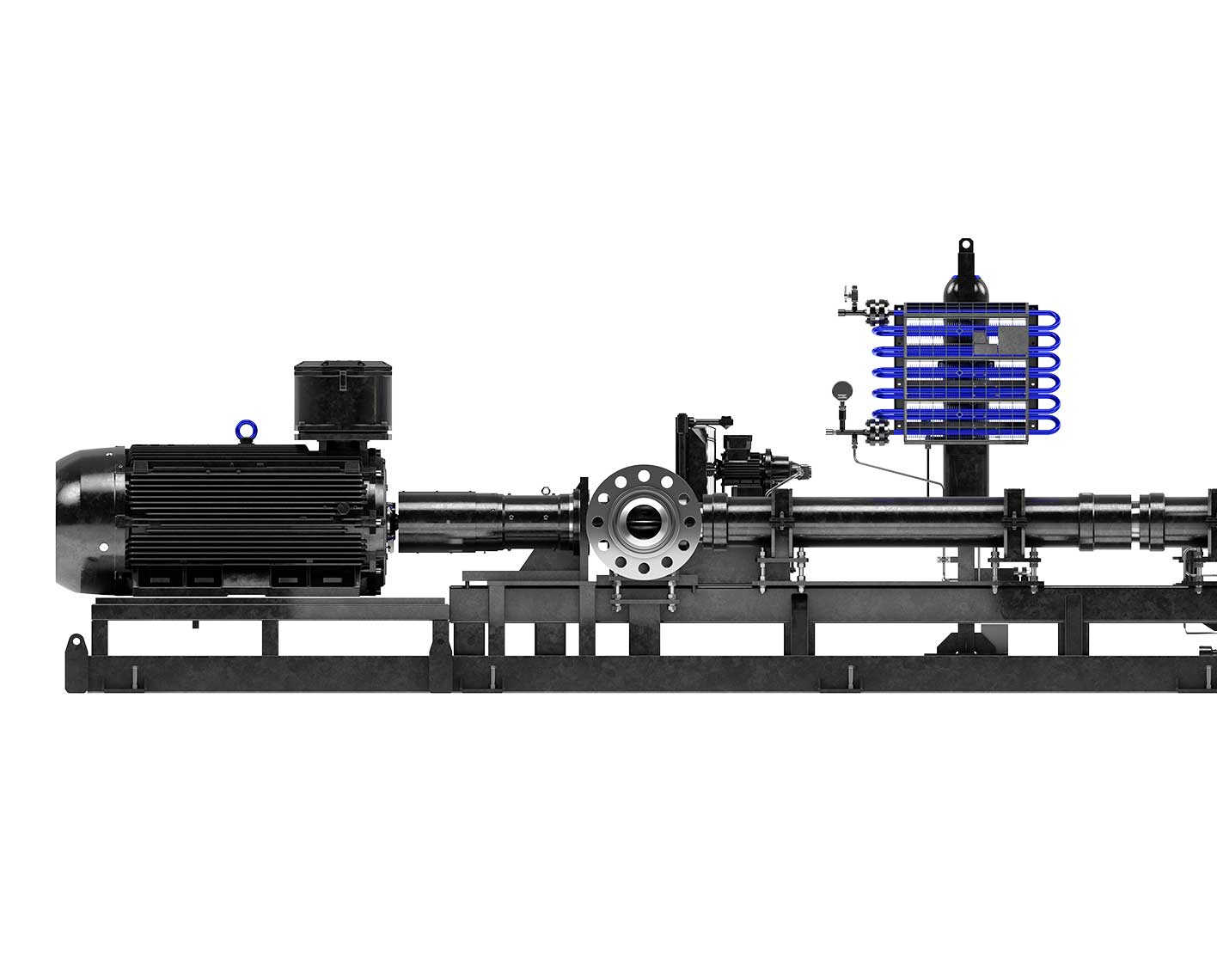

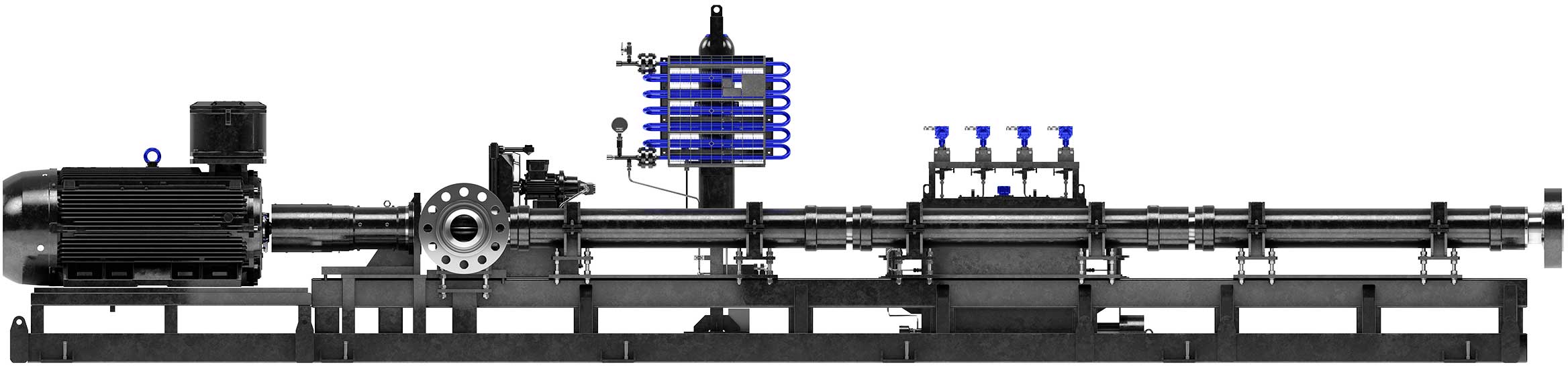

Reda Multiphase HPS™ horizontal multistage surface pump improves the efficiency of boosting and transporting unprocessed crude oil and gas, eliminating the need for phase separation. Because it addresses the limitations of conventional surface centrifugal pumps, the Reda Multiphase HPS pump is ideal for zero-flaring operations to enhance production from wells and transfer raw gas and commingled oil fluids to a central processing facility.

In addition to eliminating costs of wellhead equipment and separators, the technology enables wells to produce at a lower wellhead flowing pressure, facilitating more aggressive reservoir drawdown that increases oil recovery.

Monetizes gas instead of flaring it by pumping multiphase fluids to a central processing facility and reduce greenhouse gas emissions by up to 99%*.

Produces at lower wellhead flowing pressure for more aggressive reservoir drawdown.

Eliminates storage tanks and trucking by using pipelines with multiphase boosting to a central processing facility.

Efficient boosting of multiphase fluids to central processing facilities, without the need for conventional gas separation equipment, can eliminate routine gas flaring. Eliminating gas flaring contributes to a substantial reduction in CO2 and CH4 greenhouse gas emissions and enables monetization of the gas.

The Reda Multiphase HPS pump design is an enhancement of the reliable Reda HPS horizontal multistage surface pumping system, using axial stages based on the field-proven MGH multiphase gas-handling system. The pump efficiently boosts crude oil with gas content up to 90% in continuous operations.

Assembled pumps are delivered to your site, ready for operations. Each pump is instrumented for remote monitoring of crucial operating parameters to protect equipment and analyze performance.

The design facilitates rapid maintenance for reduced downtime via improved configuration of pumps, thrust chamber, seal, and motor.

Flow rates from 3,150 to 50,000 bbl/d [500 to 8,000 m3/d]

Gas volume fraction up to 90%

Max. boost pressure 900 psi [6,200 kPa]

*The qualification is based on well test and well unloading operations in 19 wells with CO2e emissions reductions up to 99.6% comparing conventional service set up with separator and gas flaring versus Reda Multiphase HPS pump power consumption to boost all liquid and gas to the production line without gas flaring.

The Reda Multiphase HPS horizontal multistage surface pump is part of Transition Technologies portfolio and minimizes carbon footprint by reducing or eliminating flaring. This portfolio of technologies provides alternative solutions that avoid flaring while driving high performance, reliability, and efficiency.

Learn moreThe content of this publication has not been approved by the United Nations and does not reflect the views of the United Nations or its officials or Member States.