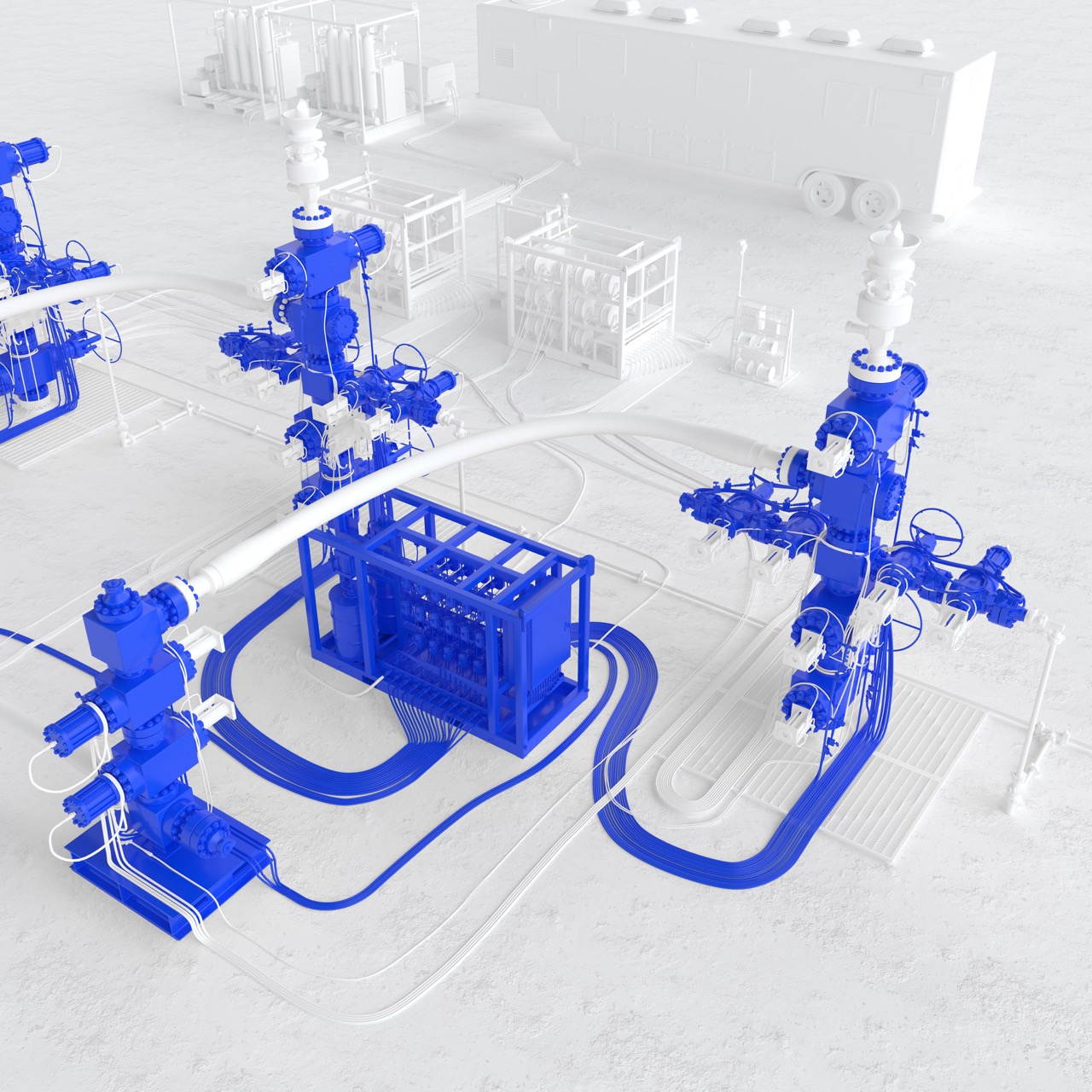

Cameron Frac Valves

Maximize fracturing efficiency with reliable high-pressure valves that eliminate wellsite greasing

Advanced sealing mechanism of frac valves improves job efficiency and safety, reduces footprint and costs.

Valves on the frac tree and manifold need regular maintenance (grease injection) during hydraulic fracturing operations. The automated valve greasing system’s remote operating capability eliminates the need for personnel to enter the red zone for valve greasing and reduces maintenance time by up to 25%. A fully automated option completely eliminates greasing from the critical path, saving you money and achieving first production sooner, with fewer people on location.

The system comprises a remote-control skid that houses a human-machine interface (HMI) outside the red zone and a grease-injection unit (GIU) that is placed in the red zone.

25%

Reduction in maintenance time20%

Less grease consumption100%

Fewer personnel in red zone0

Valve greasing on critical pathValve maintenance during hydraulic fracturing operations

The software initiates condition-based maintenance using intuitive detection and operational awareness. When valve maintenance conditions are met, a high-pressure pump on the grease injection unit automatically pumps grease to the valve. This minimizes risk of human error, as well as HSE exposure. Dual grease pumps on each skid improve performance and reliability.

The optimal volume of grease is determined at the user interface via feedback from instrumentation. Grease consumption decreases by as much as 20%. Because no personnel enter the red zone, normal fracturing operations can continue on other wells, further improving wellsite efficiency.

Class I Div. 1 hazardous-area-rated grease injection unit

Pressure sensors on all valve cavities

Remote or fully automated mode

Full traceability on all greasing operations