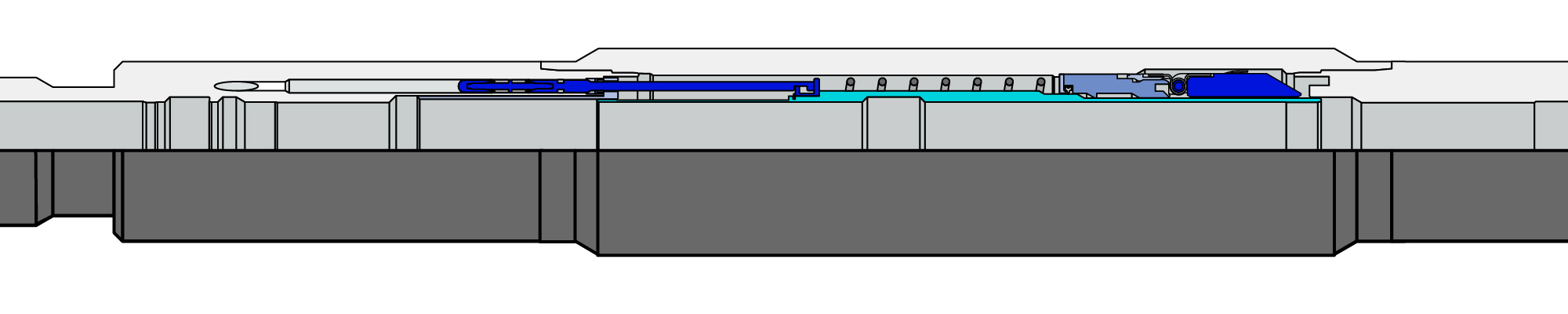

TRMAXX

Surface-controlled subsurface safety valves

- Sweet to severely corrosive environments

- Oil and gas wells, CCS wells

- Minimizes risk with fewer potential leak paths

- Increases reliability by protecting the hydraulic piston bore

- Enables flapper pressure equalization without compromising reliability

- Minimizes solids and scale deposition

- Lowers workover costs by enabling use of simple slickline interventions for lockout and hydraulic communication

- Extends service life by reducing operating friction and resisting corrosive chemicals

- Validation to API Spec 14A V1-R

- Field-proven INCONEL® 718 flapper and seat with secondary soft seat

- Flapper-mounted, dart-based equalizing system

- Static, metal-to-metal or metal-to-PEEK hydraulic end seals in open and closed positions

- Metal-to-metal premium connection body seals

- Rod-piston actuator with nonelastomeric dynamic seals

- Hydraulic system rated 15,000 psi [103 MPa]

- Sliding components with optimal geometry and

clearance

INCONEL is a registered trademark of Special Metals Corporation.

How are the valves qualified?

The valves are validated to API Spec 14A V1-R, but their performance exceeds the certification requirements.

Flapper leakage: API Spec 14A allows leakage up to 5 ft3/min. The acceptance criterion for TRMAXX safety valve flapper systems is 150 times more stringent.

Hydraulic actuator integrity: API Spec 14A allows up to 5% drop in applied hydraulic pressure; for 10,000-psi hydraulic pressure, the acceptable leakage is 500 psi. TRMAXX safety valve actuators allow <1% drop, as confirmed by rigorous tests.

Slam closure: The valve's flapper system has been successfully slam tested at high flow rates that exceed the Annex K requirements of API Spec 14A.