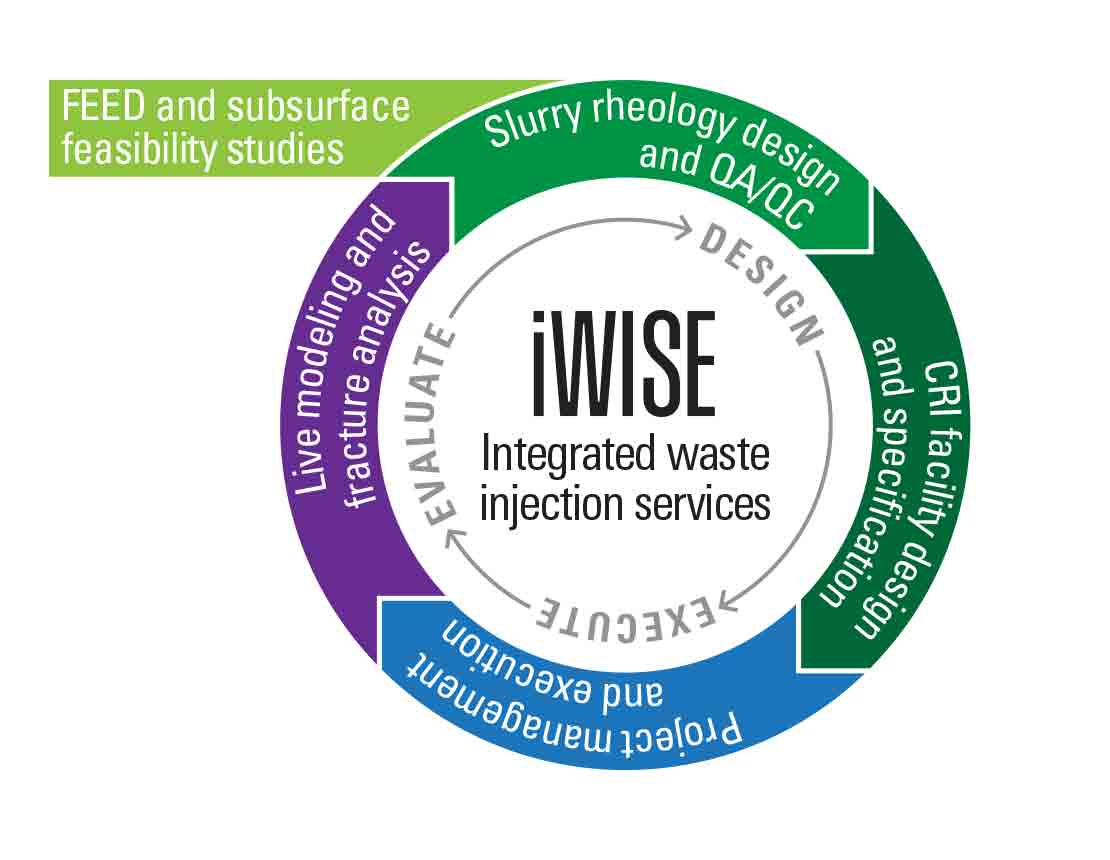

iWISE

Integrated waste injection services

Balanced

Effective

Reliable

Flexible

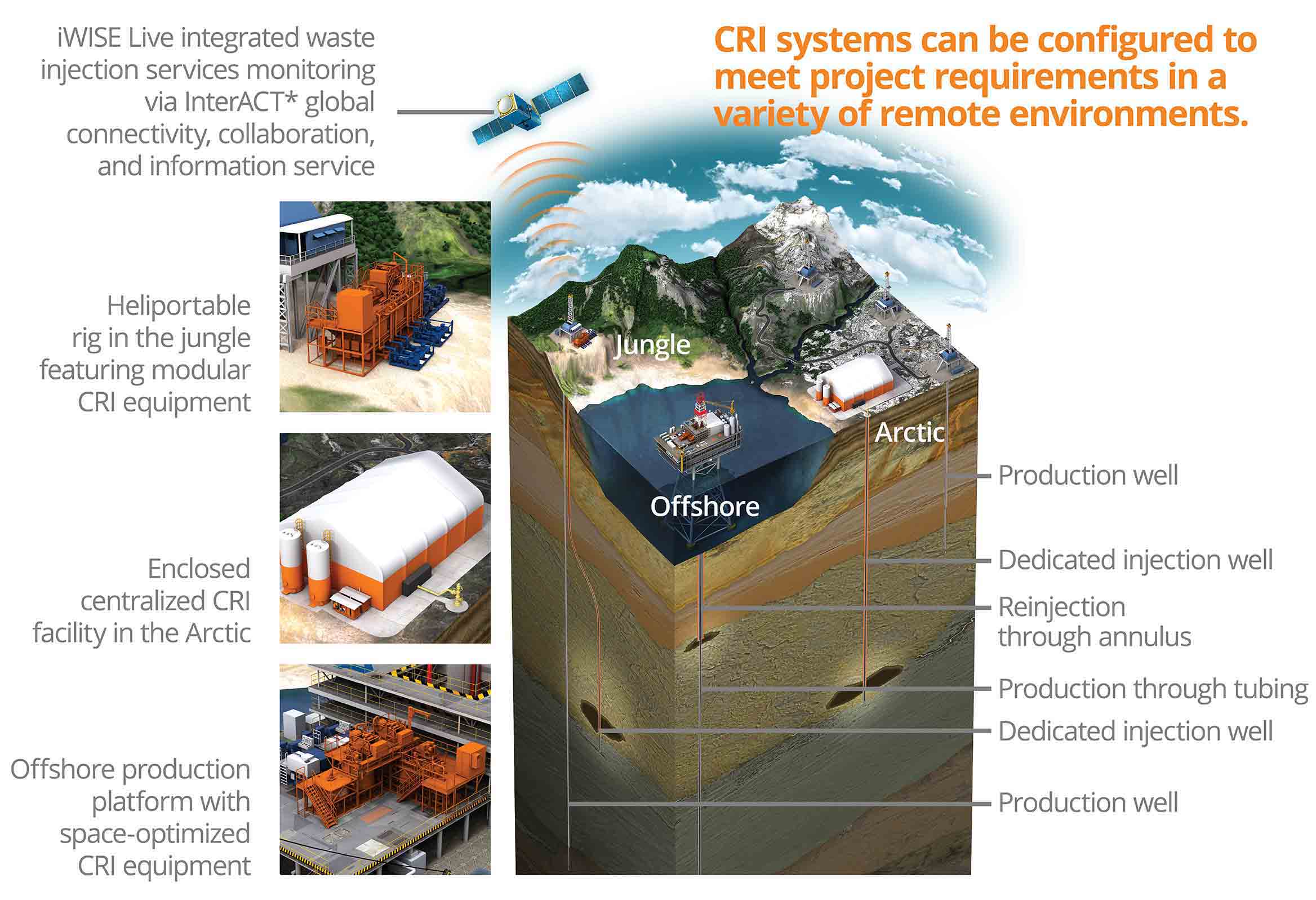

Field-proven cuttings reinjection (CRI) technologies, workflows, and services in one comprehensive solution

For large and valuable reservoirs in locations that are both remote and environmentally sensitive, cuttings reinjection (CRI) can be the cost-effective, comprehensive solution for drilling waste management that meets or exceeds the most stringent environmental standards.

Limiting the risks and achieving the unequaled benefits of CRI requires surface and subsurface engineering analysis and diagnostic expertise—before, during, and after the operation.

iWISE services comprise field-proven CRI technologies, workflows, and services in one comprehensive solution that enables us to deliver single-source, start-to-finish CRI solutions—on time, on budget, and within environmental constraints.

Design

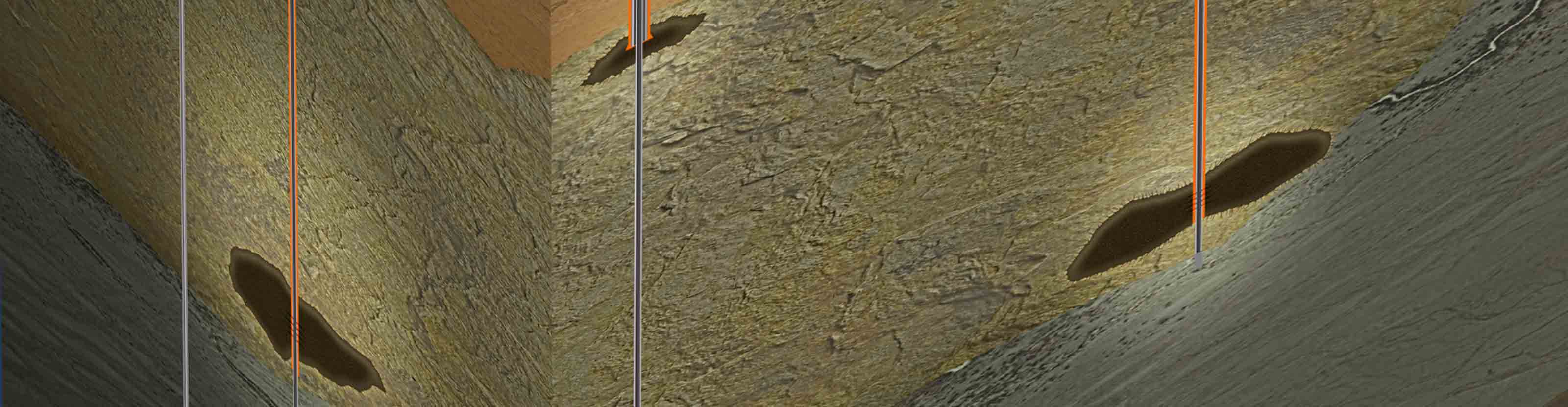

- PowerFEED front-end engineering design (FEED) and subsurface feasibility studies

These comprehensive analyses address geological uncertainty and complexity—such as intersections of the fracture and pore domain with natural faults or well trajectories—to enable defining injection parameters, establishing drilling and completion plans, and determining surface facility requirements and procedures.

- Slurry rheology design and QA/QC

Poor slurry rheology and design can result in plugged wells or unwanted erosion or corrosion. Comprehensive testing and assessment ensure a reliable fluid design that can optimize completions and production results without compromising drilling quality.

- CRI facility design and specification

With a solid understanding of subsurface requirements, iWISE services experts can specify and customize the necessary surface equipment and facilities to optimize your HSE profile and overall productivity.

Execute

- Project management and execution

We bring together the optimal plan, people, and equipment to deliver the project on time with minimal supply disruptions, safer operation, and reliable management. Our close integration with sister companies enables process and cost optimization through multiskilling and equipment synergies.

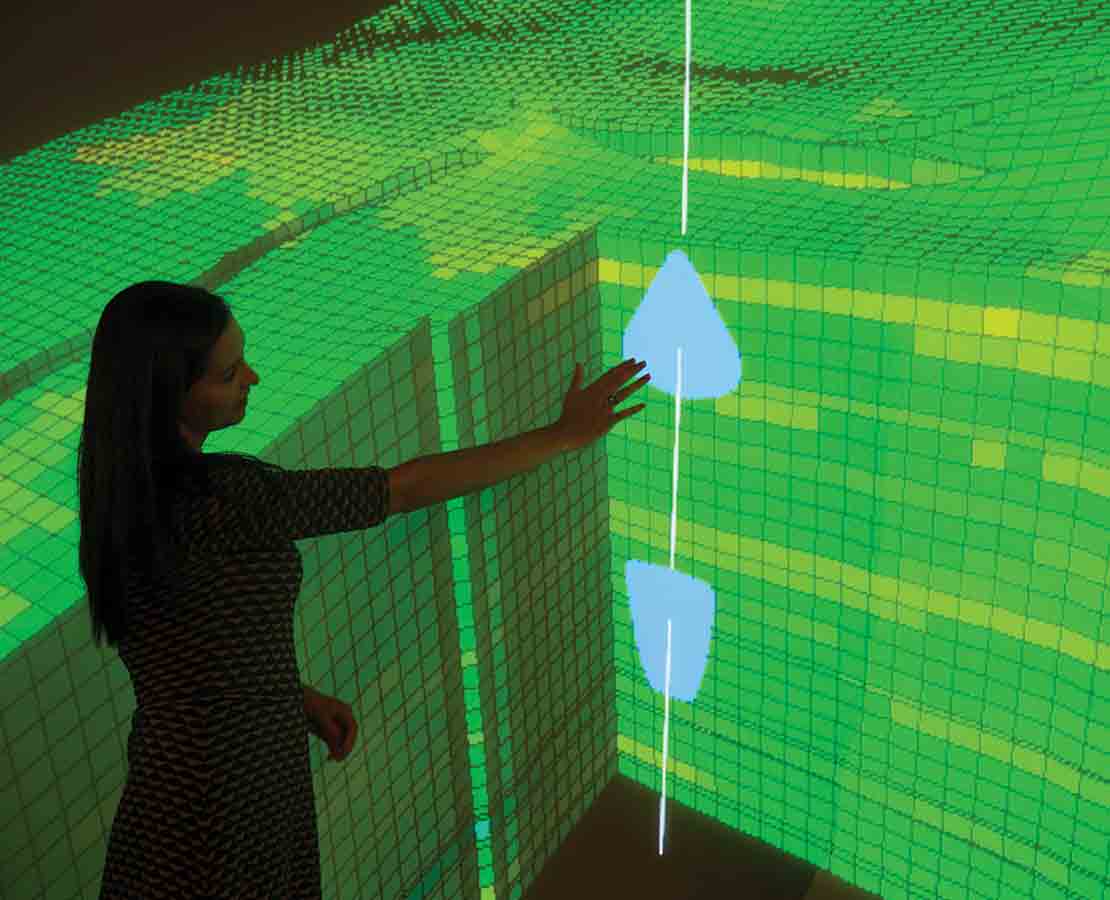

Evaluate

- iWISE Live integrated waste injection services monitoring