CCS well design

Injectivity assurance and long-term integrity

Maximize project success with wells engineered for CCS performance.

The EverCRETE™ CO2-resistant cement system serves as barrier for CO2 storage wells or high-CO2-producing formations. In addition, the system can be used to cement new CO2 injection wells or to plug and abandon injection or production wells at the end of the field life. EverCRETE system lowers the CO2 footprint during well construction due to significantly reduced usage of portland cement. In addition to being used as a cement across potential CO2-producing formations, it can act as the primary barrier in the wellbore for in situ fluids after abandonment and permanent decommissioning. For wells in fields that use CO2 injection for enhanced oil recovery (EOR) or may use it in the future, EverCRETE system reduces the risk of cement sheath degradation and leakage.

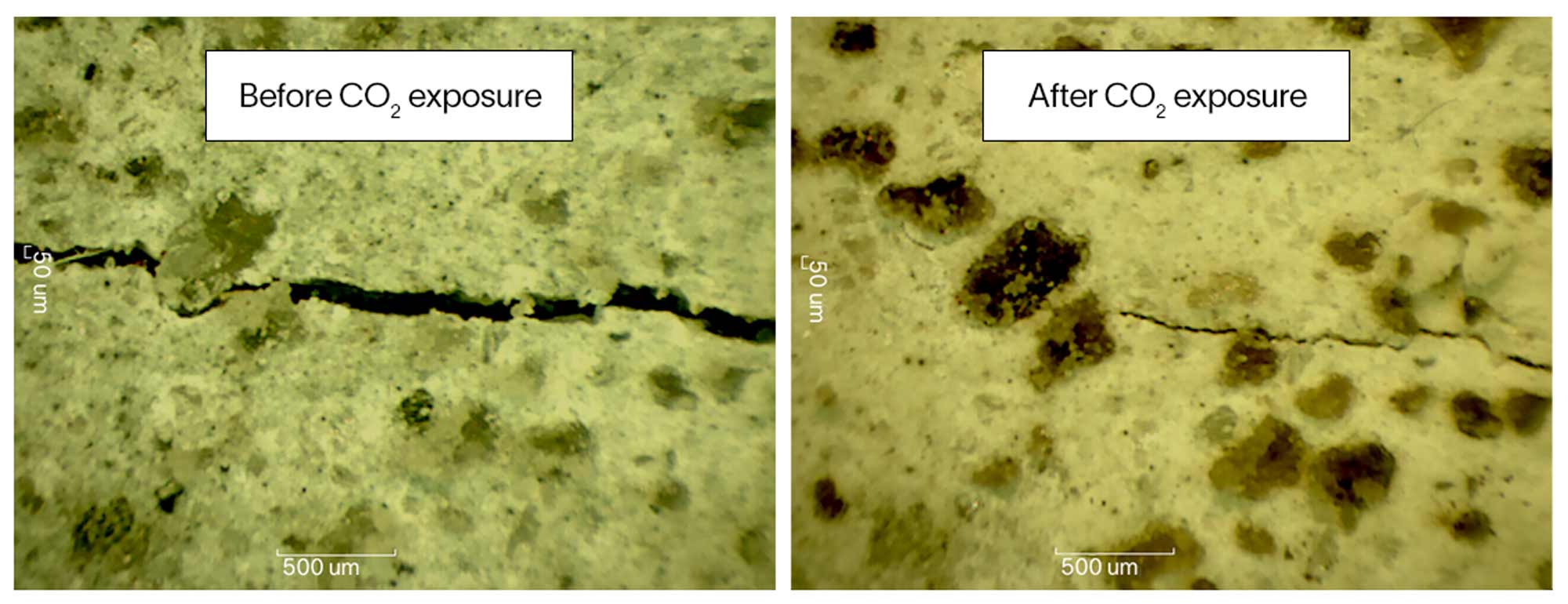

In case there is damage to the cement matrix and CO2 starts to migrate, the self-healing capabilities that can be incorporated in EverCRETE system will repair the crack, reestablishing the integrity of the well and recovering zonal isolation.