SlurryAirSeparator

Mechanical cement slurry defoamer

Improve slurry quality with environmental compliance, and eliminate foaming problems.

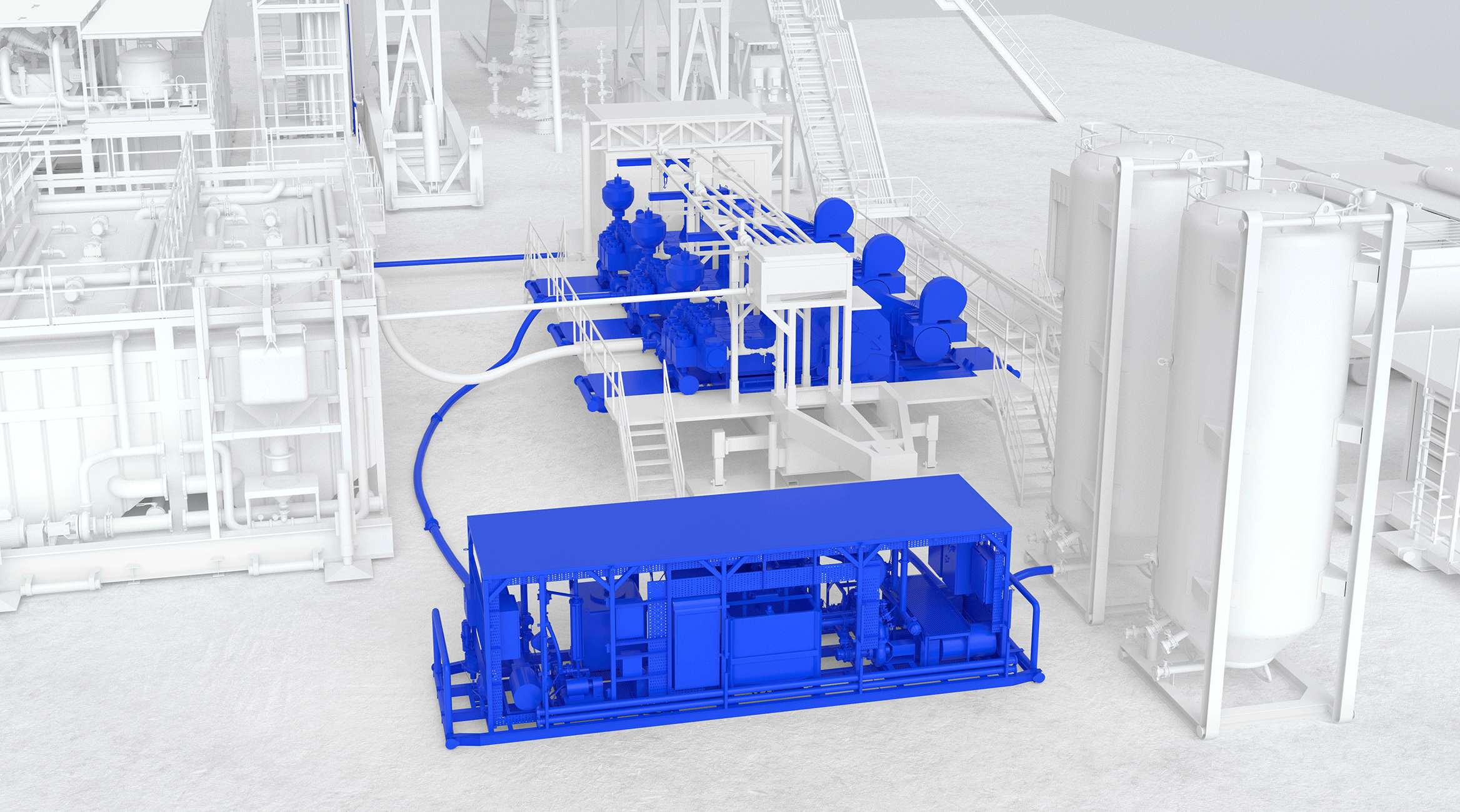

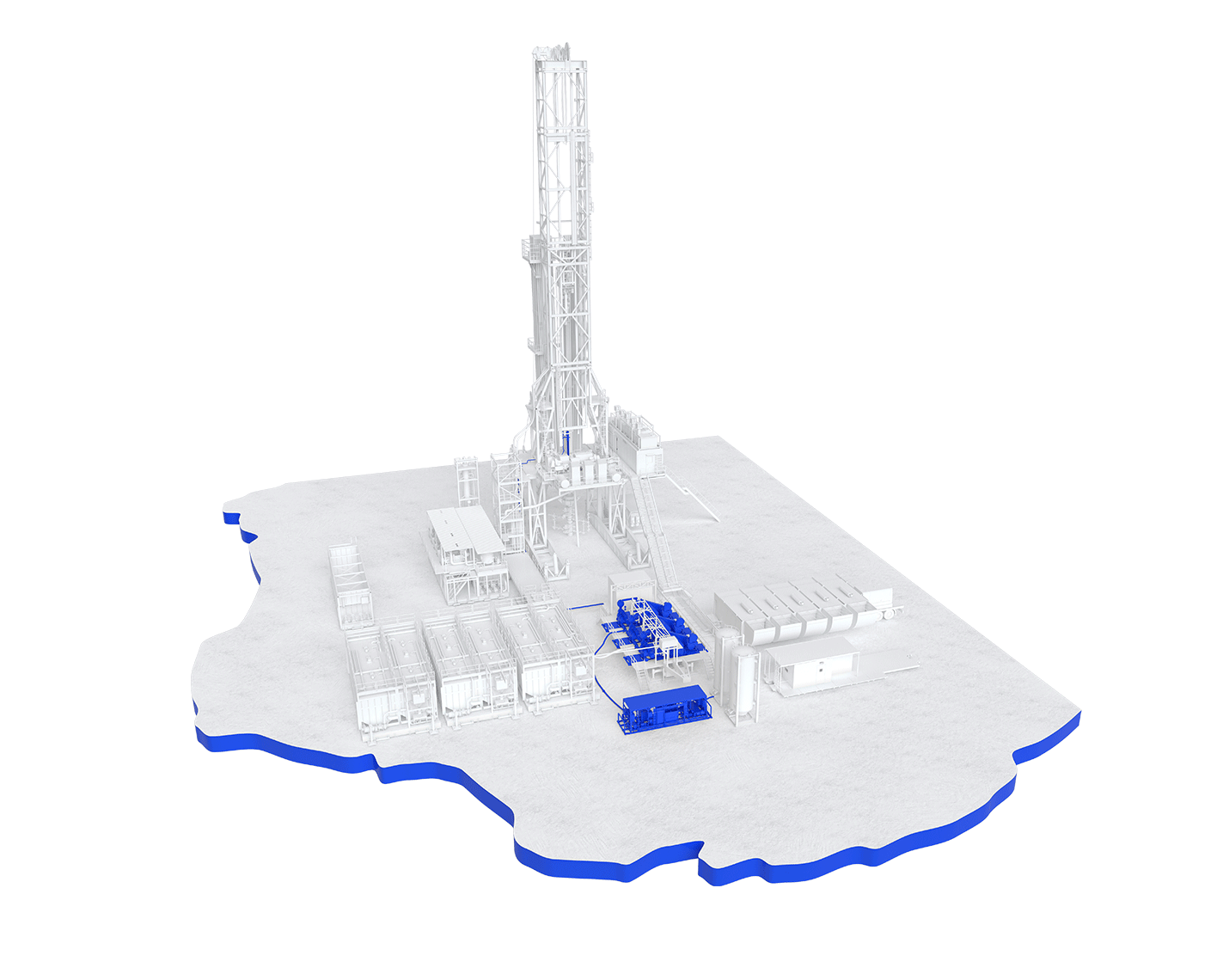

The rig-enabled cementing service mixes and transfers cementing slurry to the rig pumps using a powerful electric cementing mixing skid. This unit is installed at the rig site, which moves with the rig as needed. The cementing slurry is mixed onsite, along with chemical additives, and is delivered to the rig pumps for pumping downhole. Integrating the cementing delivery equipment and rig system simplifies maintenance, streamlines job execution, and reduces the logistics involved in the well construction process.

Land drilling operations

Primary and remedial cementing jobs