Wireline Powered Intervention

Reinvent your interventions

Set new standards for success in well intervention operations with real-time monitoring, dynamic tool control, and verified downhole actuation.

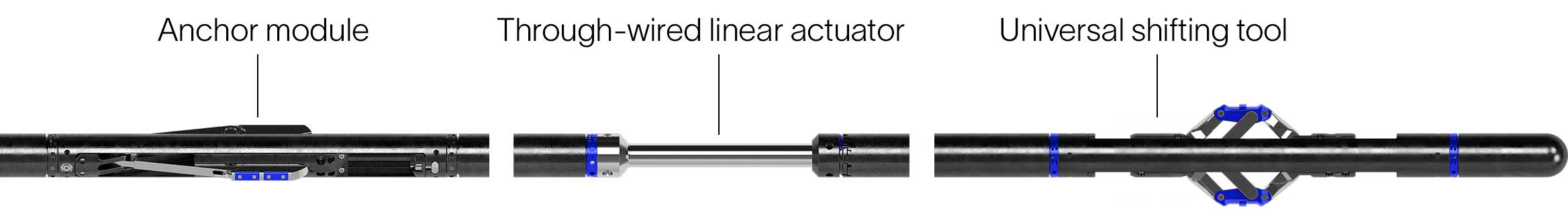

The ReSOLVE Family™ instrumented wireline intervention services provide reliable shifting of toolstrings and components using an anchor, linear actuator, and universal shifting tool (UST). The UST works with both the 3 1/8-in ReSOLVE™ instrumented wireline intervention service for normal well conditions and the 2 1/2-in ReSOLVE iX™ intelligent extreme wireline intervention service for complex completions with small restrictions in sour and HPHT environments.

By combining through-wired instrumentation, high-resolution sensors, and precise mechanical actuation, ReSOLVE Family services eliminate the uncertainty of conventional wireline shifting methods. Engineers can monitor tool activity in real time, verify actual downhole movement, and adjust operations dynamically, which reduces intervention time and increases operational certainty. This integration of sensing, control, and actuation enables multiple objectives—such as logging, diagnosing, and shifting—to be achieved in a single descent, improving efficiency and reliability.

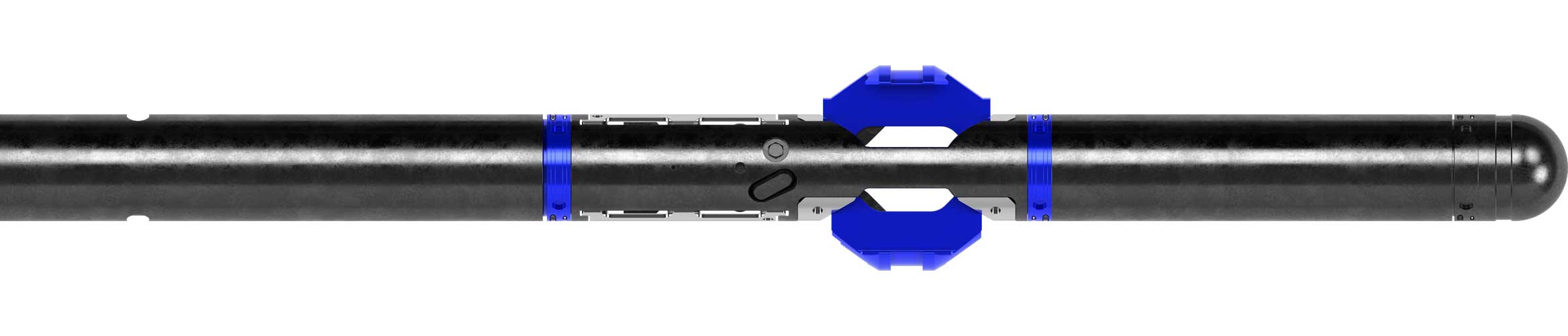

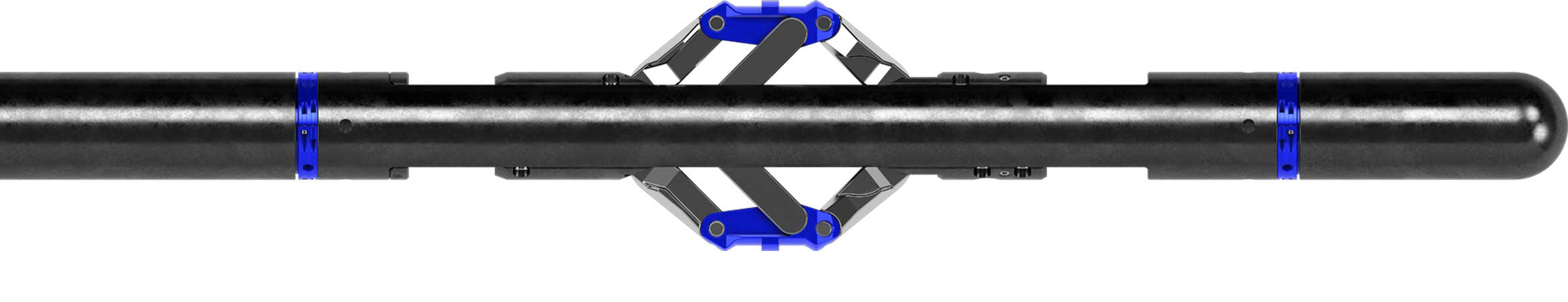

The ReSOLVE Family UST delivers reliable shifting by combining secure anchoring, controlled actuation, and real-time verification. Diameter changes are detected to ensure accurate latching, and each shift is confirmed by measuring force against displacement for a unique valve fingerprint. These measurements provide positive confirmation of completion and reveal unexpected downhole conditions for faster remediation.

The tool can be conveyed by gravity on wireline or by tractor in highly deviated and horizontal wells. Its keys open or close on command, and the bidirectional linear actuator enables multiple shifts in either direction during a single run. Continuous monitoring of displacement, applied force, and adjustable radial key force ensures precise tool control at all times.

Fully through-wired, the UST combines seamlessly with production logging, well integrity, and other intervention services. Standard and custom key options allow configuration for any shifting pro le, providing a universal solution that adapts to all downhole conditions.

This integration of anchoring, actuation, and verification delivers faster, more certain interventions while achieving multiple objectives in a single descent.