Modular operational flexibility

Despite its compact length, the TuffTRAC tractor has multiple built-in systems for electrical release, head tension, shock absorption, casing collar log, and addressable tractor perforating safety switch. The result is increased operational safety, reliability, and versatility. TuffTRAC configurations typically employ two to four drive sections. Adding a tandem sub enables independent surface control of the drives above the sub from those below. Up to eight drive sections can be run to push heavy loads in difficult completions. The TuffTRAC Mono tractor can accommodate up to six drive sections.

Powered for maneuverability

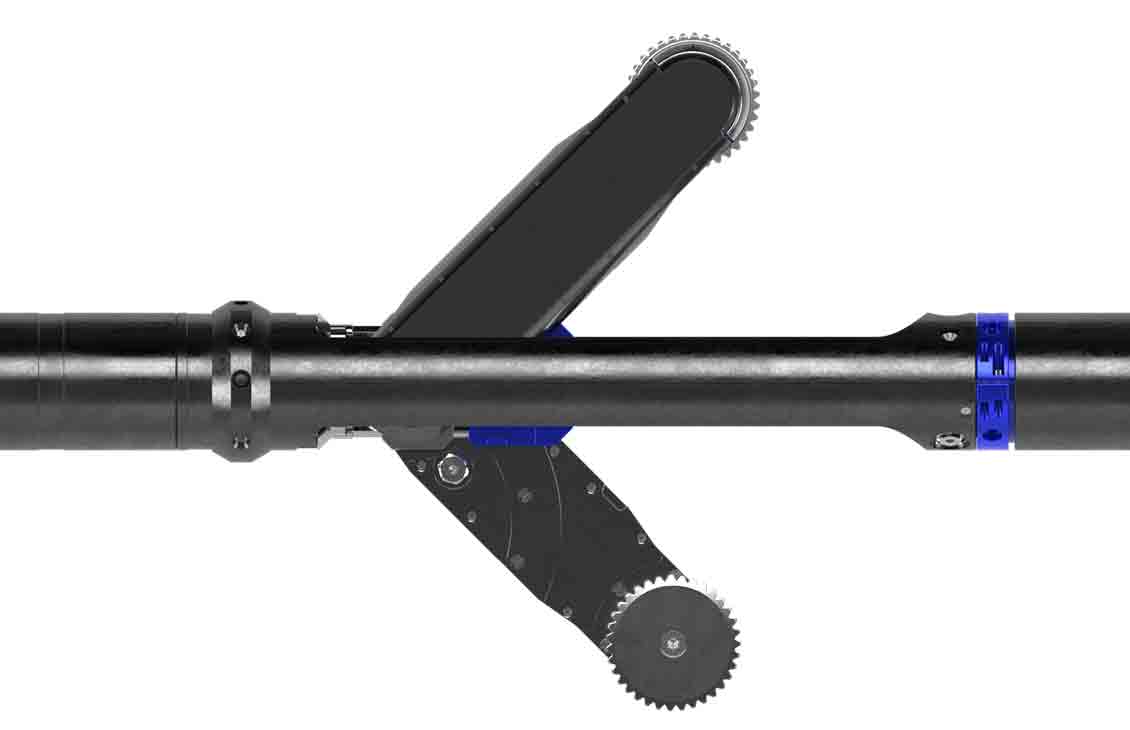

The electromechanically driven TuffTRAC wheels optimize available surface power, achieving more than 45% conversion efficiency from the supplied electrical power. The low power requirements do not stress auxiliary systems nor does the tractor need stopping to cool down, even in dry gas wells.

Exclusive to TuffTRAC operations, active traction control continuously controls the radial force applied by the tractor arms. If slippage is detected, the radial force can be raised to increase the traction and then decreased once the difficult section is successfully traversed. Because the radial force applied by the arms is independent of borehole size, the TuffTRAC drives can achieve the same tractoring force in borehole IDs from 3.4 to 10.6 in [8.6 to 26.9 cm].