Modum Flow

Flowmetering system

Calculate production flow in real time to enable data-informed decisions about well testing frequency.

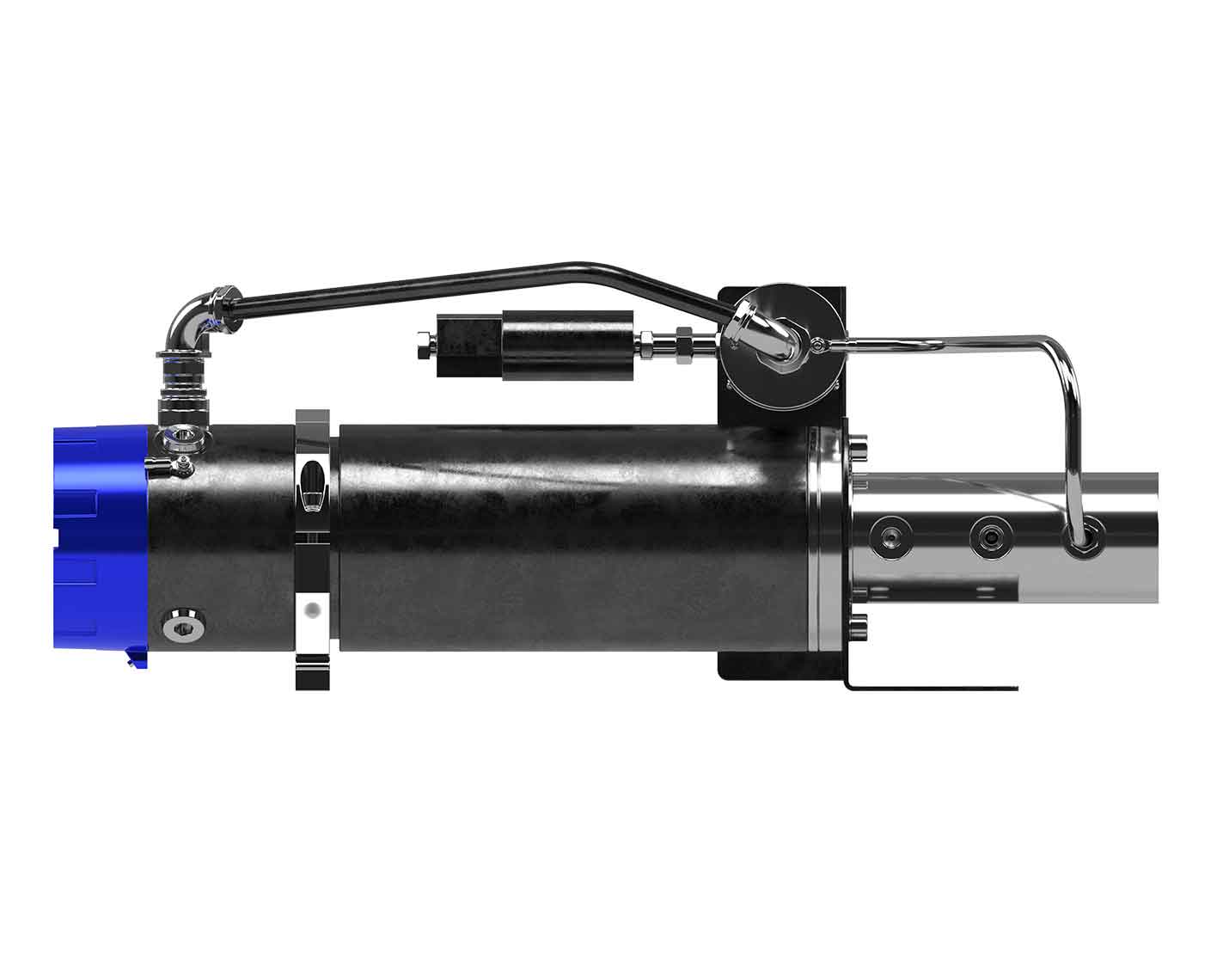

Modum Chem™ chemical injection metering control system is a smart device that reduces your chemical injection costs and environmental footprint—without increasing the risk of flow disruption.

The smart valve system measures and controls the flow rate of chemicals passing through it to maintain an optimal target flow rate, improving performance over that of traditional injection rate control devices. The technology also enables remote adjustments to accommodate changing well, surface, and system conditions.

Its accurate control means you can use a single chemical reservoir and pump to inject chemicals into a multiwell system, with smart valves regulating injection into each well.

Plus, the compact design facilitates integration into skid packages or wellsite infrastructure without requiring significant modifications to your existing chemical injection system.

Onshore and offshore surface applications