DrillPlan

Coherent well planning solution

Produce better-quality drilling programs in minutes.

Published: 08/13/2025

Published: 08/13/2025

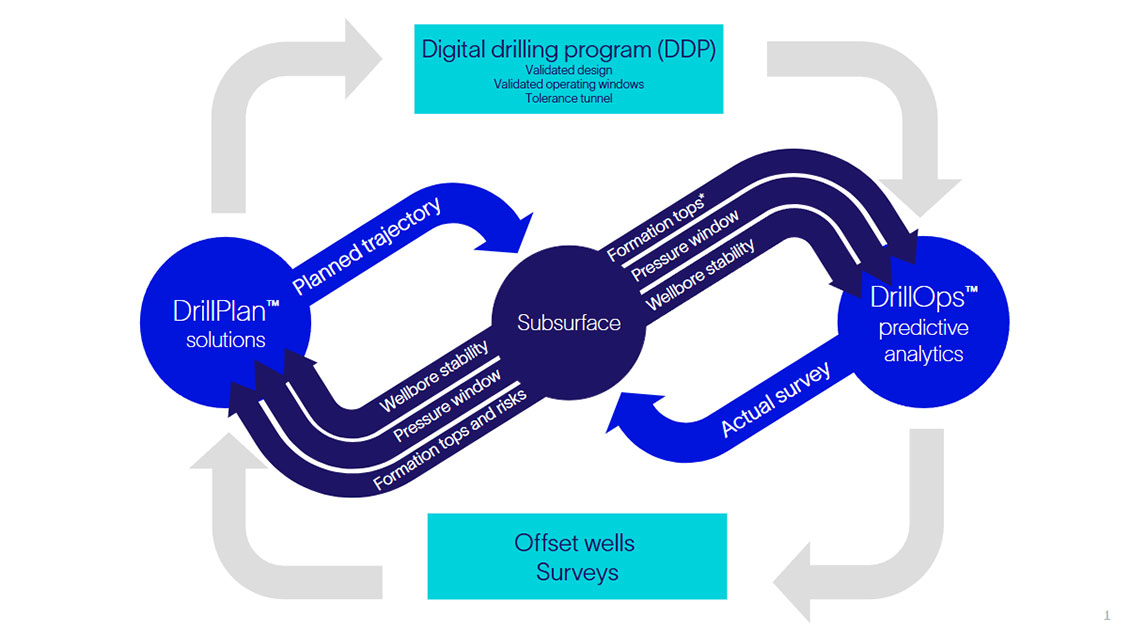

In the complex world of oil and gas exploration and field development, the interface between subsurface and drilling teams has long been a bottleneck. These two groups often face challenges in attempting to seamlessly share data and insights. However, advancements in digital technology are now transforming this dynamic, enabling more integrated workflows and better decision-making. This article explores how innovative solutions, such as DrillPlan™ coherent well planning and engineering solutions and DrillOps™ well delivery and insights solutions, are bridging this gap and revolutionizing well planning and operations.

Subsurface and drilling teams rely heavily on each other’s outputs. For instance, the planning team depends on subsurface data such as wellbore stability assessments, pressure windows, formation tops, and potential hazards. Conversely, the subsurface team requires updated well trajectories, precise surface locations, and 3D well paths to generate these outputs. This circular dependency has historically led to inefficiencies, delays, and miscommunication.

Recognizing this challenge, SLB set out to create a digital solution that integrates these workflows, enabling seamless collaboration between the two groups. The result is a suite of tools that leverages cloud-native technology to streamline data exchange and automate critical processes.

The updated real-time pressure and geomechanics windows are then used in DrillOps solutions to enhance detection of risks and to optimize the drilling processing.

DrillOps solutions run several real-time engines:

These engines operate continuously, using real-time inputs such as MWD/LWD data, mud properties, and flow rates, as well as the updated pressure and geomechanics limits coming from Geomechanics Insights. The system can detect early signs of instability and suggest proactive measures, such as increasing mud weight or initiating hole cleaning.

The seamless integration between DrillPlan solutions, DrillOps solutions, and Geomechanics Insights exemplifies the power of digital technology in breaking down traditional silos. By automating data exchange and integrating workflows, these tools enable subsurface and drilling teams to work collaboratively and efficiently. This not only reduces planning and operational delays but also ensures that every well is drilled better than the last.

The ability to iterate designs, update models, and make real-time decisions based on the latest data represents a step change in well planning and operations. It empowers teams to optimize performance, reduce costs, and enhance safety, all while leveraging the full potential of digital technology.

The integration of subsurface and drilling workflows through tools like DrillPlan solutions and DrillOps solutions can be transformational for the oil and gas industry. By bridging the gap between these traditionally siloed teams, SLB is enabling a new era of efficiency, collaboration, and innovation. As digital technology continues to evolve, the potential for ever more advanced workflows and capabilities is almost limitless. With these tools, the industry is well-positioned to meet future challenges and unlock new opportunities for growth and success.

Thomas Murray

DrillPlan Product Manager

Thomas is product manager for DrillPlan™ coherent well planning and engineering solutions and is responsible for the development of this cloud native software.

Thomas has worked for SLB for over 15 years in a variety of roles, functions, and geographic locations. Starting as a field engineer in Azerbaijan, he later moved into R&D, spanning mechanical design, project management, and software product management. He has contributed to a range of cutting-edge oilfield technologies, including the Ora™ intelligent wireline formation testing platform, broadband acoustic seismic source, and in the last six years, DrillPlan solutions.

Maurice Ringer

DrillOps Product Manager

Maurice is product manager for DrillOps™ intelligent well delivery and insights solutions, and is responsible for digital products relating to monitoring, analyzing and optimizing drilling operations at SLB.

Maurice holds a PhD from Cambridge University, where he studied signal analysis, Bayesian inference, modeling, and optimization. He then joined SLB where he has been involved in drilling automation and real-time drilling in one form or another for more than twenty years, from MWD engineer to directional drilling, to developing new AI/machine learning (ML) techniques at the SLB Cambridge Research Centre, to mud logging project manager, to DrillOps solutions product manager.