Let AI driven workflows execute autonomous operations.

Redefining drilling performance: How DrillOps automation and DrillOps advisory are powering autonomy in operations

Published: 08/26/2025

Redefining drilling performance: How DrillOps automation and DrillOps advisory are powering autonomy in operations

Published: 08/26/2025

A new chapter in drilling innovation

The world of upstream oil and gas is high stakes and the pressure to drill faster, more safely, and more efficiently has never been greater. As the industry grapples with increasingly complex well designs and ever shrinking profit margins, digital transformation has evolved from a specialized differentiator to a foundational strategy for staying competitive. At the forefront of this evolution are DrillOps™ automation and DrillOps advisory, next-generation drilling automation solutions that leverage autonomous AI to transform how wells are drilled.

This article explores how these solutions go beyond just automating tasks to autonomously navigate the drilling process and deliver measurable improvements in performance, safety, and consistency.

From automation to autonomy: understanding the journey

To fully appreciate the impact of DrillOps intelligent well delivery and insights solutions, it’s important to distinguish between automation and autonomy. Automation refers to systems that follow predefined instructions. For example, think of a driller using an automated iron roughneck or auto pipe handler. These are helpful tools, but they operate within rigid, linear workflows.

Autonomy, on the other hand, introduces the intelligence that enables systems to perceive, make decisions, and adapt to changing conditions, to manage multiple workflows simultaneously. SLB defines this progression through a six-level model:

- Level 0: No Automation. Fully manual operations.

- Level 1: Assistance. The equipment can assist a human with a task but cannot perform it alone (e.g. robotic iron roughneck).

- Level 2: Task automation. The system can perform predefined tasks standalone including one or more piece of equipment. (e.g. connection automation).

- Level 3: Conditional autonomy. The system perceives its environment and makes its own decisions within set constraints while executing a workflow (e.g. slip-to-slip automation).

- Level 4: High autonomy. The system executes complex tasks independently and reliably across varied scenarios, with humans stepping in only for rare exceptions. (e.g. full section automation).

- Level 5: Full autonomy. The system operates independently under all conditions.

DrillOps operates at the higher end of this spectrum, delivering a seamless blend of surface and downhole autonomy, orchestrated by a powerful AI engine.

The brain behind the operation: AI-driven planning

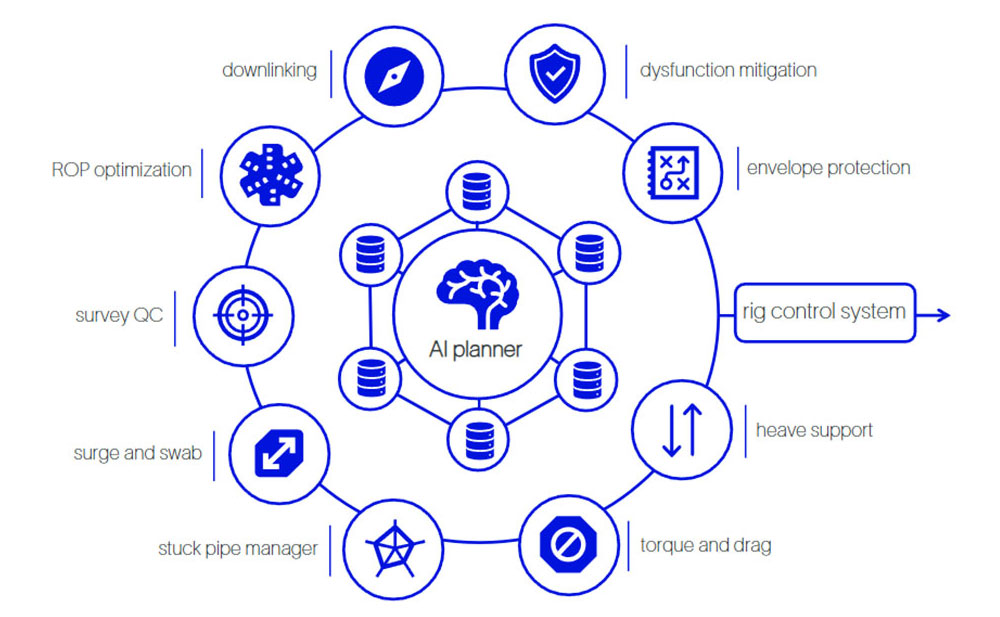

At the core of both DrillOps automation and DrillOps advisory is an intelligent AI planner. This engine acts as the central conductor that orchestrates a suite of specialized drilling domain engines, designed to analyze and interpret the complexities of the drilling environment. The optimization and risk avoidance insights they generate are then prioritized and translated into informed decisions and actions by the AI planner. With these intelligent engines in place, drilling boundaries can be dynamically recalculated in real time, ensuring operations consistently achieve maximum efficiency while proactively minimizing risks. Examples of these domain engines are shown in the image below:

With the AI planner acting as an intelligent orchestrator, it dynamically manages priorities across the engines, ensuring that critical tasks are addressed first while enabling parallel execution when appropriate. This coordination enables the engines to collectively contribute to optimal performance. Balancing efficiency and risk mitigation in this way enables a level of perception and adaptiveness that transforms DrillOps solutions into a truly autonomous system.

Pushing the boundaries: expanding the operational envelope

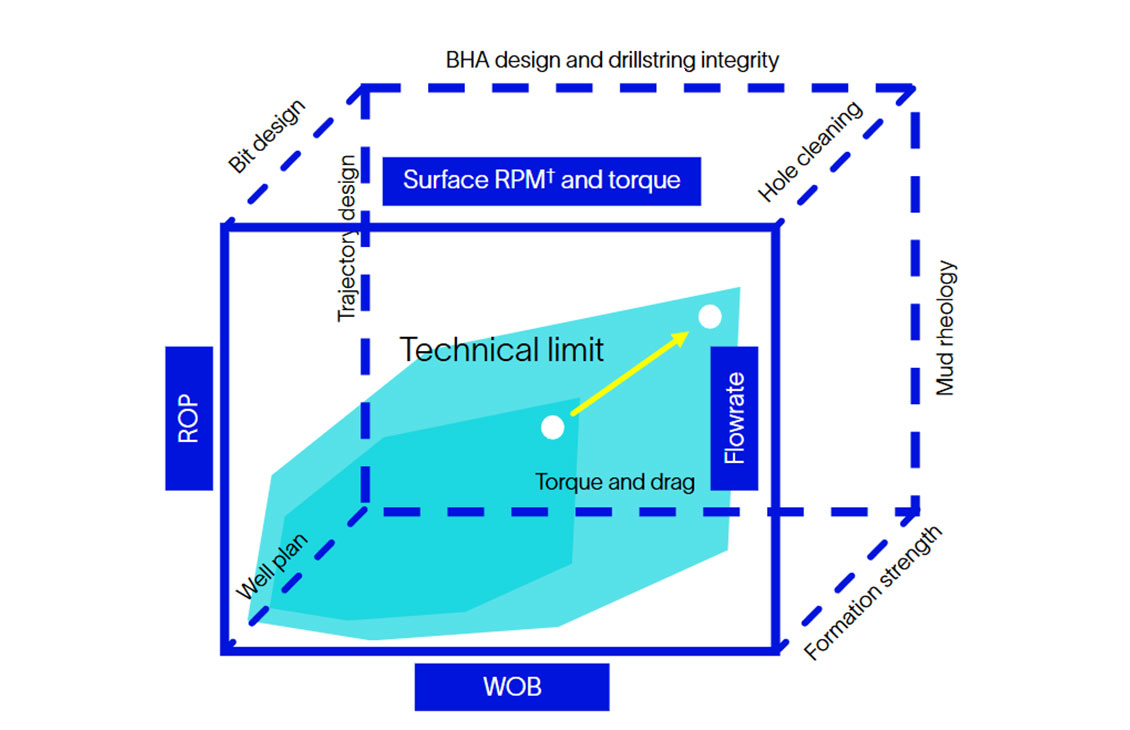

Traditional drilling roadmaps require extensive engineering work upfront. These pre-built plans are intentionally conservative, including historical biases, and are designed to account for a variety of scenarios, all resulting in considerable margins of error. While this approach ensures safety and reliability, it often leaves performance potential untapped because the roadmap cannot adapt to real-time changes in downhole conditions.

By leveraging real-time data and advanced engineering capabilities running at the rig, dynamic roadmaps, enabled by smart autonomous drilling systems, transform the process. Rather than adhering to static limits, they enable:

- Intelligent, real-time adjustments closer to technical limits

- Safer yet more efficient operations

- Optimized performance in ever-changing conditions

This is not just about pushing boundaries. It is about operating smarter, balancing safety with performance, and unlocking better outcomes for every stage of the well’s lifecycle.

Deployment done right: process meets mindset

While technological innovation is a crucial foundation, technology alone doesn’t drive transformation—people do. That’s why SLB emphasizes two pillars for successful deployment of DrillOps solutions.

1. Process: structured, scalable, reliable

Deployment begins with installation and commissioning, to ensure seamless integration with rig control systems. This is followed by a hypercare phase, where SLB experts provide hands-on support to resolve early issues. Once stabilized, operations transition to a steady-state model, backed by managed services for continuous monitoring, updates, and expert guidance.

2. Mindset: embracing change, trusting data

True transformation requires more than technical readiness; it demands a cultural shift. Teams must move from experience-based decision-making to data-driven execution. Key mindset principles include:

- Linking automation to measurable KPIs (e.g., ROP, flat time, NPT)

- Aligning with strategic goals (e.g., standardization, invisible loss reduction)

- Starting small, scaling smart (e.g., targeting specific workflows like connection procedures)

- Fostering engagement and feedback (e.g., reviewing automated suggestions, refining configurations)

- Committing to continuous improvement (e.g., post-job reviews, iterative updates)

When teams understand the “why” behind each recommendation, trust grows, and so does performance.

Proof in performance: a real-world success story

One operator’s experience with DrillOps solutions illustrates its transformative potential. By deploying the solutions across their rig fleet, they achieved:

- 40% reduction in drilling duration (from 40 days to ~25 days)

- 2x increase in ROP

- 50% reduction in weight-to-weight time

- 25% increase in tripping speed

By leveraging autonomous drilling technology to eliminate biases and accurately identify the true safe boundaries, they were able to push closer to the real technical limits of drilling. This breakthrough led to a step change in performance, demonstrating the potential benefits from shifting from traditional manual drilling to modern, automation-enabled operations.

The future is autonomous

DrillOps solutions are more than digital tools; they are strategic enablers. By integrating intelligent automation with a disciplined deployment approach and a forward-thinking mindset, SLB empowers operators to achieve unprecedented levels of efficiency, safety, and consistency.

As the industry continues to evolve, tools like DrillOps solutions will be indispensable in navigating future challenges. By transforming data into actionable insights and translating those insights into tangible results, DrillOps solutions are set to lead the way in the autonomous future of the industry.

James Cahalane

Digital Product Manager

James Cahalane serves as product manager for DrillOps solutions, where he oversees a suite of digital solutions designed to automate and provide expert guidance for surface, downhole and directional operations. Additionally, he is responsible for advancing edge infrastructure, and streamlining and enhancing rig-based workflows.

James has a master’s degree in applied geophysics from the University of Galway, Ireland. He joined SLB initially as a field engineer, working in various locations, both on land and offshore, globally. For the last 10 years he has led deployment and support of drilling automation solutions.

Abeer Musbah

Drilling Operations Deployment Manager

Abeer is a deployment project manager, leading the rollout of DrillOps solutions across Europe and Africa. She is responsible for managing deployments for DrillOps automation, DrillOps advisory, DrillOps performance insights, and DrillOps predictive analytics. Abeer ensures that all deployments are strategically planned, efficiently executed, and aligned with the global standards and best practices of SLB,

Abeer holds a BSc in mechanical engineering from the University of Khartoum, Sudan and began her career as a drilling and measurements field engineer, gaining hands on experience across various field locations. She has since held diverse roles in operations support centers, well placement, and sales.