Let AI driven workflows execute autonomous operations.

Breaking the silo: Why true orchestration is the missing ingredient in drilling automation

Published: 05/20/2025

Breaking the silo: Why true orchestration is the missing ingredient in drilling automation

Published: 05/20/2025

Breaking the silo: Why true orchestration is the missing ingredient in drilling automation

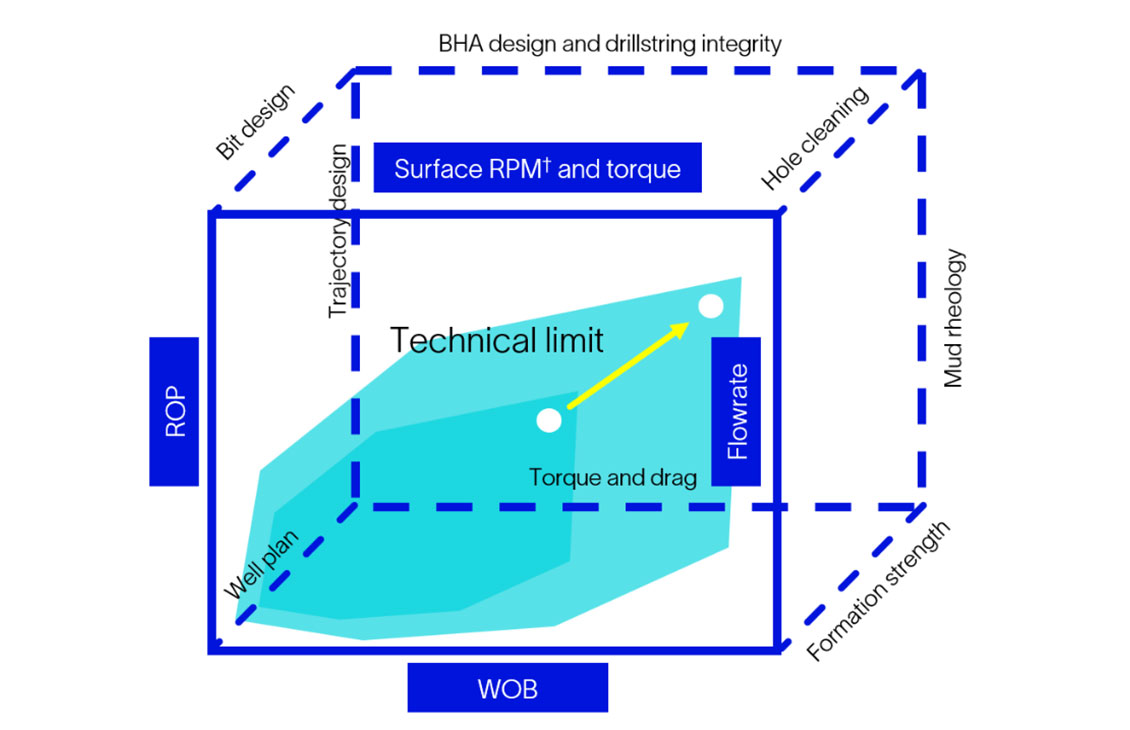

In the continuous evolution of digital solutions for well construction, the drive for efficiency and safety has given rise to countless products across the entire well construction ecosystem with solutions now on offer to address nearly every drilling challenge. However, these tools are often developed independently overlooking a fundamental reality: every drilling action triggers a chain reaction, with consequences stretching far beyond its immediate scope. The reality on the rig is that drilling is not a sequence of independent steps, but an ecosystem where every action interacts with broader operational goals, and each optimization creates ripple effects that must be balanced across the operation.

The challenge: Siloed optimization, and why it falls short

Operators across the energy sector know the story all too well. A software solution pushes performance in one area, for example increasing rate of penetration (ROP), while neglecting the downstream effects on cuttings transport, tool reliability, or wellbore stability. Without systems that truly understand and balance competing objectives, the unintended outcome can be suboptimal compromises, increased manual coordination for rig experts, or the need to invest significant resources in integrating disparate products and systems.

The problem is compounded by the fact that each customer has unique constraints, priorities, and business drivers. Software that’s built with one customer’s set of objectives in mind forces other customers to make uncomfortable compromises or spend significant resources knitting together disparate products. Too often, the responsibility for ensuring that all these tools speak the same language, without working at cross-purposes, falls back on the rig team, turning intended automation benefits into new sources of coordination overhead.

Moving beyond the status quo: the value of platform-level orchestration

To move beyond this challenge, the industry requires solutions that look holistically at well construction. Systems that connect the dots, dynamically weighing trade-offs, and coordinating actions according to the full spectrum of operational, safety, and business objectives. Rather than adding more isolated tools, the focus moves to building unified solutions that progressively incorporate insights from each new customer-selected domain engine. This ensures each additional domain engine enhances the system’s overall intelligence rather than adding to the complexity, fully leveraging the strengths of every engine. As a result, the system achieves dynamic, real-time optimization across multiple domains while maintaining rigorous risk management.

Acknowledging the problem: the new paradigm in solution design

Recognizing the limitations of fragmented solutions, DrillOps™ automation leads a new generation of rig automation technology built on a foundation of coordination and customized control.

At their core, DrillOps intelligent well delivery and insights solutions begin with one of the industry’s most comprehensive portfolios of domain engines, built on decades of drilling engineering, downhole modeling, and simulation expertise. These engines supply detailed, real-time insights across a wide range of operational factors, enabling a nuanced understanding of the current drilling context and the flexibility to reflect specific customer priorities.

Building on these real-time insights, the AI planner in DrillOps automation operates like an advanced solver. It continuously draws on the full context provided by the domain engines to adaptively select each operational step, tailored precisely to customer objectives and rig-specific standard operating procedures (SOPs). Rather than rely on static, pre-set sequences, the AI planner has no predefined templates and instead generates bespoke action plans each time the user adjusts their objective, or well conditions change.

DrillOps automation continuously evaluates the entire operational landscape, intelligently balancing the varying priorities, risk levels, and urgencies presented by each domain engine, enabling it to coordinate and respond to multiple, sometimes simultaneous, demands in real time. So, automated decisions fit the unique conditions and priorities present at any given moment.

Finally, DrillOps automation translates these insights directly into real-world rig actions. By seamlessly connecting with rig equipment, including mud pumps, drawworks, top drive, and the autodriller, the system can execute the recommended actions with machine-level precision. Its highly customizable setup ensures that every action aligns with customer-specific standard operating procedures (SOPs). Throughout the process, the driller remains fully informed, with clear visibility into the system’s decision-making logic and its ongoing actions. Whenever desired, the driller can instantly regain manual control simply by touching the controls. Thanks to continuous AI-driven planning, the system stays in sync with operations and can also resume automated control whenever needed, delivering both safety and efficiency without compromising oversight.

Unifying decades of innovation: deep integration in DrillOps automation

A key reason DrillOps automation stands out is its ability to harness intelligence from some of the most advanced technologies developed by SLB, refined through decades of innovation and fine tuning. Seamless integration with solutions such as Neuro™ autonomous directional drilling enables the system to automatically incorporate directional commands into its decision-making, ensuring optimal well trajectory without manual intervention. By connecting directly to DrillOps predictive analytics, DrillOps automation receives a continuous stream of high-value insights, such as transient hydraulics simulations for hole cleaning and surge and swab, powered by advanced domain engines and access to high-performance computing. Additionally, DrillOps automation can automatically ingest replans and SOP changes from DrillPlan™ coherent well planning and engineering solutions, keeping operational strategies current and aligned with evolving objectives. Through these deep integrations DrillOps automation achieves a uniquely rich operational context, empowering it to make the most informed decisions possible and delivering superior outcomes across the full spectrum of drilling operations.

Bridging digital transformation: DrillOps advisory for mixed automation landscapes

Many rigs are at different stages of digital transformation meaning while some rigs are ready for full automation, others may already have a rig automation system in place or may not be automatable. In these situations, DrillOps advisory offers all the intelligence and advanced domain models of DrillOps automation in an advisory format. So, drillers are empowered to leverage AI-powered recommendations while retaining full manual control. Where a rig automation system is already in place, SLB has established agreements with many rig vendors, enabling subsets of DrillOps automation technology to be deployed alongside existing systems. This approach allows operators to augment and enrich their current capabilities with advanced insights and analytics, benefiting from the latest innovations without the need for a complete system overhaul.

Empowering the next generation of drilling operations

As the industry advances toward truly unified, intelligent, well delivery solutions, systems like DrillOps solutions are closing the gaps between siloed optimization and whole-system orchestration. By harnessing integrated, real-time AI insights and equipment connectivity, operators can maximize operational efficiency and safety, no matter where they are on their digital transformation journey.