An intelligent, automated, real-time multi-well monitoring alarm based advisory system, detecting, and predicting drilling events .

From data to predictions: Unlocking potential with DrillOps™ predictive analytics

Published: 09/19/2025

From data to predictions: Unlocking potential with DrillOps™ predictive analytics

Published: 09/19/2025

In the high-stakes world of drilling operations, every second counts, and every decision can have significant implications for cost and safety. The need for smarter, faster, and more efficient solutions has never been greater. DrillOps™ predictive analytics, a next-generation, cloud-deployed solution, is designed to transform the way drilling operations are monitored and managed. By harnessing the power of automation and integration, it lightens the workload for engineers, simplifying many tasks and providing valuable insights to enhance operational efficiency. This approach is setting a new standard for operational excellence, helping operators reduce costs, minimize risks, and scale their operations with greater confidence and efficiency.

At its core, DrillOps predictive analytics focuses on addressing some of the most persistent challenges in the industry. Non-productive time (NPT) and invisible lost time (ILT) have long been the bane of drilling operations, leading to delays, cost overruns, and inefficiencies. DrillOps predictive analytics tackles these issues by automating many traditionally manual workflows and integrating data and insights across multiple domains. The solution enhances engineers’ capabilities by streamlining complex processes and providing them with actionable insights, freeing them from tedious tasks like interpreting raw data. This enables them to put more focus on decision-making ensuring that wells are delivered on time, within budget, and as planned.

Automation: the key to drilling efficiency

One of the most transformative aspects of DrillOps predictive analytics is its ability to automate and accelerate tasks that were once labor-intensive and time-consuming. Historically, drilling operations heavily relied on experts manually verifying data quality, configuring and calibrating models, and interpreting data and model results from various sources. This process was generally slow and prone to human error, leading to missed opportunities for optimization or early intervention.

DrillOps predictive analytics simplifies these workflows by streamlining the QC process for rig data, automatically retrieving context from the drilling plan and geomechanical studies, and running advanced computations to interpret the data, all in real time. With many of the foundational tasks automated, engineers’ focus can remain on higher-value activities such as advanced engineering and strategic decision-making.

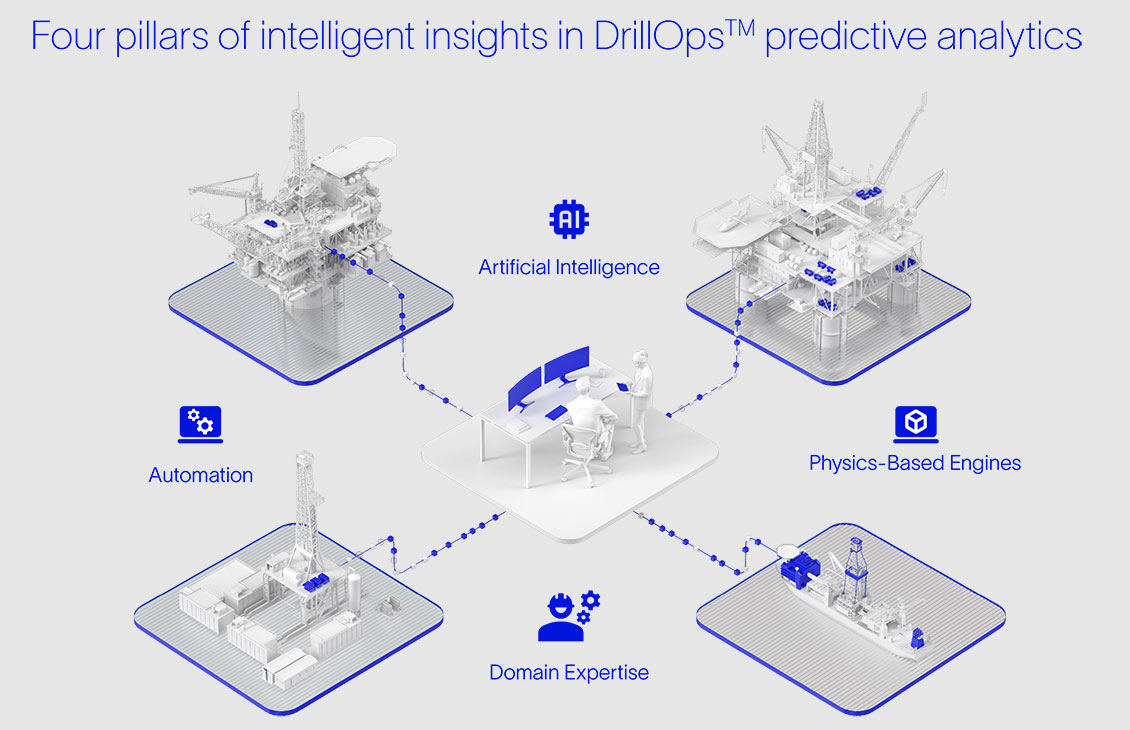

Powered by smart engines, combining AI and physics-based models, the solution analyzes real-time drilling conditions to identify potential issues, such as excessive pressure, drill string integrity risks, or mud weight window violations. These smart engines don’t just flag anomalies but provide context-aware insights that help teams assess the severity of a situation and take appropriate action. By reducing the time spent sifting through raw data and analyzing time series data plots to make sense of problems, the system enables reduced response times, and less costly disruptions.

For example, if early signs of a pack-off or stuck pipe event are detected, the system doesn’t just raise an alarm. It integrates data from multiple sources and provides various pieces of context, so the engineer can analyze the situation holistically. By automating the analysis and contextualization of data, DrillOps predictive analytics not only accelerates decision-making, it also reduces response times, and prevents costly disruptions assisting with actionable recommendations, transforming operational outcomes.

Integration: elevating insights and collaboration

DrillOps predictive analytics takes a hybrid approach by combining traditional physics-based models with AI-driven techniques, leveraging the strengths of both. Physics-based models provide a solid foundation for understanding drilling dynamics, while AI models learn from real-time and historical data to enhance accuracy and adaptability. This balance ensures the system can adjust to changing conditions and deliver reliable insights, even in complex scenarios.

The insights and capabilities described above are further strengthened through integration with a robust data foundation, that gathers information from a wide range of sources. DrillOps predictive analytics stands out for its comprehensive access to every key variable, fostering a unified ecosystem where data flows smoothly across systems and domains. This integration is not just a technical feature; it’s a strategic enabler that allows automation to deliver its full potential.

DrillOps predictive analytics also integrates seamlessly with other SLB solutions, enhancing workflows across planning, execution, and monitoring. Integration with DrillPlan™ coherent well planning and engineering solutions enables the automatic import of key parameters, such as anti-collision tunnels, ensuring that operational plans stay aligned with real-time conditions. Similarly, through integration with Geomechanics Insights, the system can update wellbore stability and pressure windows based on real-time surveys, providing the most current inputs for its smart alarms. These integrations reduce the manual effort required to align systems and data, allowing engineers to focus on leveraging insights to optimize performance.

By connecting all critical systems and creating a streamlined data ecosystem, DrillOps predictive analytics helps teams unlock the full potential of automation and ensures that human expertise remains focused on the highest value problems. This approach fosters a collaborative environment where data, tools, and people work together seamlessly to achieve optimal results.

Looking ahead

DrillOps predictive analytics goes beyond being just another tool and provides a pathway to the future of drilling operations. By combining automation and integration, it empowers teams to make smarter, faster decisions, ensuring that operations are not only efficient but also safe and scalable. The streamlined processes, the integrated data across domains, and delivery of actionable insights it offers enables operators to address both current challenges and future complexities with confidence.

By setting new standards for what is possible in drilling operations, DrillOps predictive analytics represents a collaborative future where technology and people work together to achieve exceptional outcomes.

Graeme Paterson

Drilling Operations Product Champion

Graeme Paterson holds an honors degree in physics from the University of Strathclyde and brings over 19 years of experience in the oil and gas industry. He began his career in Well Construction in the North Sea and has since taken on diverse roles across the company, spanning Engineering, Manufacturing & Sustaining, Petrotechnical Services, Software Integration Solutions, and Digital & Integration across multiple geographic regions. Currently, Graeme serves as the Product Champion for DrillOps™ predictive analytics and is based at the Beijing Geoscience Centre in China.