Achieve unprecedented production and reservoir management.

Norwegian operator battles zonal sand production and wins!

An operator deployed Electris™ interval control valves (ICVs) with in situ flow rate, water holdup, and PT measurements to extend production from a mature field. The system provided real-time zonal flow monitoring and control, enabling swift identification and mitigation of production issues. By leveraging the electric ICVs with in situ measurements, the operator has achieved consistently higher production and uptime while minimizing interventions.

On the Norwegian continental shelf, an operator is working to extend production from a mature field characterized by reservoirs ranging from homogeneous to highly complex. The goal is to enhance production uptime while minimizing well interventions and mitigating production irregularities.

To achieve this objective, the operator deployed six Electris ICVs with in situ flow rate, water holdup, and PT measurements within a third-party gravel-packed completion. This setup enabled real-time flow monitoring and control across eight reservoir zones. Following well cleanup, production commenced with continuous data acquisition in real time providing actionable production intelligence and empowering the operator's engineers to optimize performance and improve recovery.

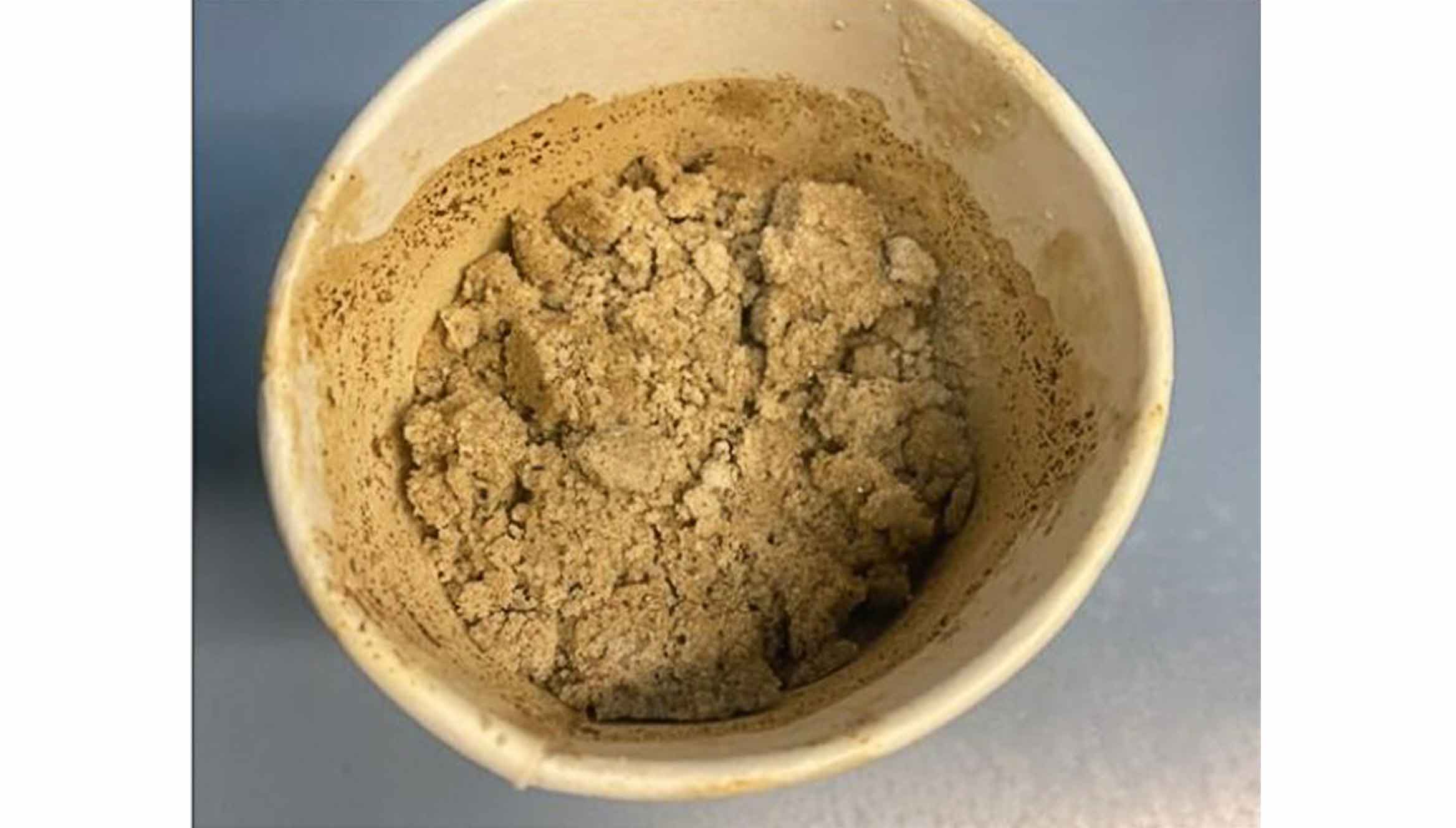

Shortly after production began, one reservoir zone at the toe of the well started producing sand and excessive water. Using data from the Electris ICV with in situ measurements and the SLB real-time equipment health and control system to drive confident action, the operator identified the issue, adapted contribution from the zone, and restored optimal flow within 12 hours.

Several months later, the best-performing zone—second from the toe and characterized by the highest reservoir pressure—began to produce sand. Leveraging the Electris ICV with continuous choke functionality, the operator’s team made precise, micrometric adjustments to manage sand production without the need to cycle the valve between fully open and closed positions (as required by conventional systems with discrete fixed settings). As a result, the zone remains one of the most productive in the well despite its tendency to produce sand at higher rates.

Without zonal monitoring and control, the only strategy for limiting sand influx would have been to reduce the total well production rate (drawdown) via the wellhead system choke. In addition to the negative impact of lower production, this solution carries the inherent risk of overcorrecting, losing lift, and sanding in the well. The ability to fine-tune zonal production in real time and monitor the results significantly improved well performance, minimized production loss, avoided costly interventions, and reduced sand disposal requirements.