Let AI driven workflows execute autonomous operations.

Unlocking potential—Equinor's journey to autonomous well delivery in the Peregrino field

A “one team” mentality combined with well thought out planning and preparations enabled Equinor to implement the highest level of autonomy, at time of drilling, in the industry.

Equinor had a goal to unlock the full potential of people and assets and execute world class well delivery. Achieving this required three things: to be performance driven and competitive, release portfolio synergies, and implement autonomous operations. This strategy included wells being digitally planned and connected, downhole and surface automation, and data driven decision making.

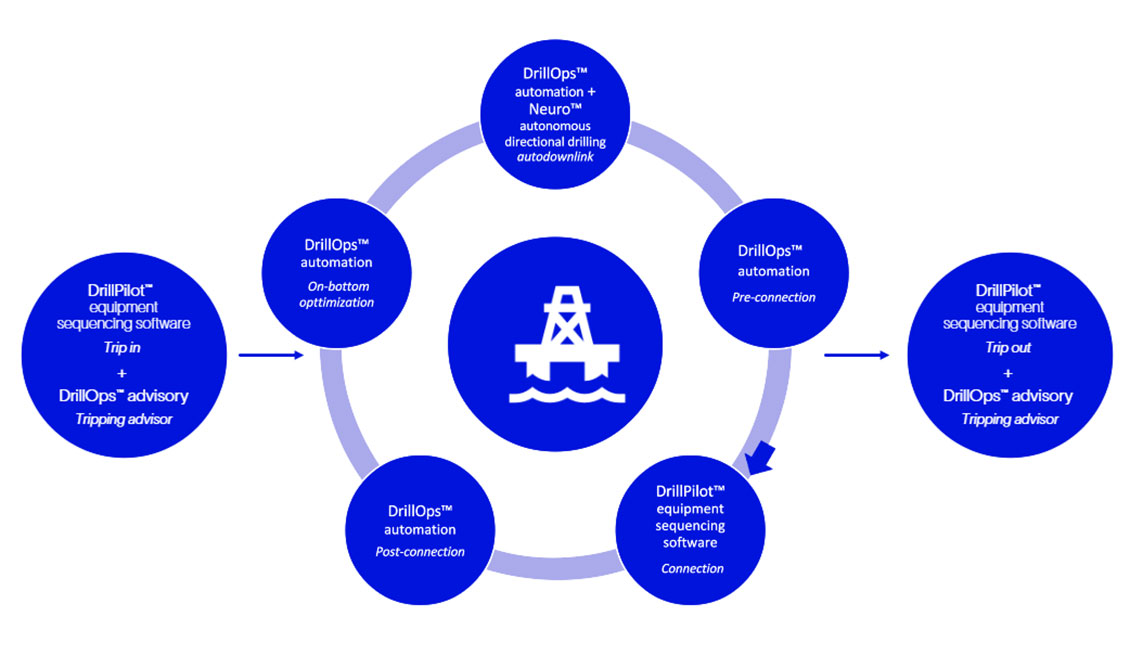

SLB delivered a total well delivery model for phase II in the Peregrino field, in offshore Brazil, and it is now in place for all 22 wells. This involved deploying many of SLB’s autonomous drilling capabilities for rig management, rig crews, and rig maintenance. A digital drilling program was developed and implemented using DrillPlan™ coherent well planning and engineering solutions and DrillOps™ orchestration, with downhole drilling automation delivered.

Familiarity with the systems was built from drill well on simulators sessions (DWOS) which began in 2020. This gave the various rig crews familiarity with the rig control system, automation systems, and operating procedures. These DWOS sessions were combined with DrillOps™ intelligent well delivery and insights solutions to record and track the crew’s performance, meaning that operational performance was elevated before even reaching the rig site.

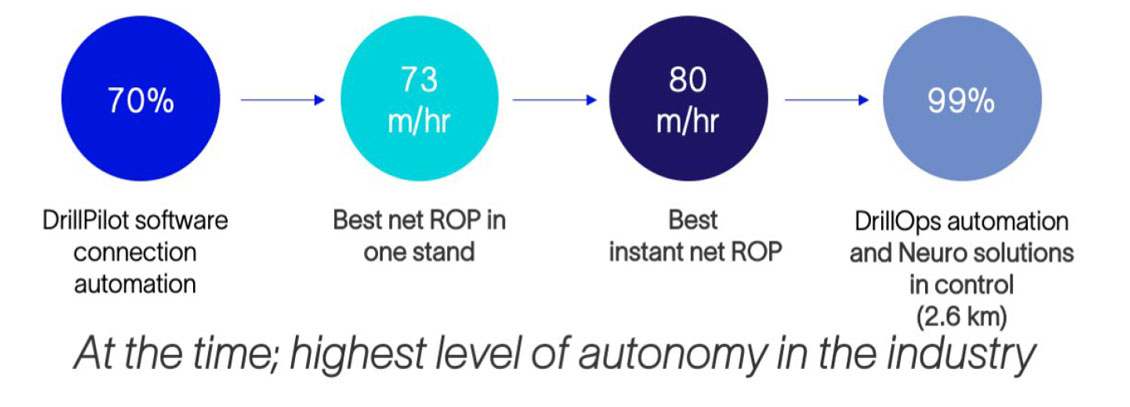

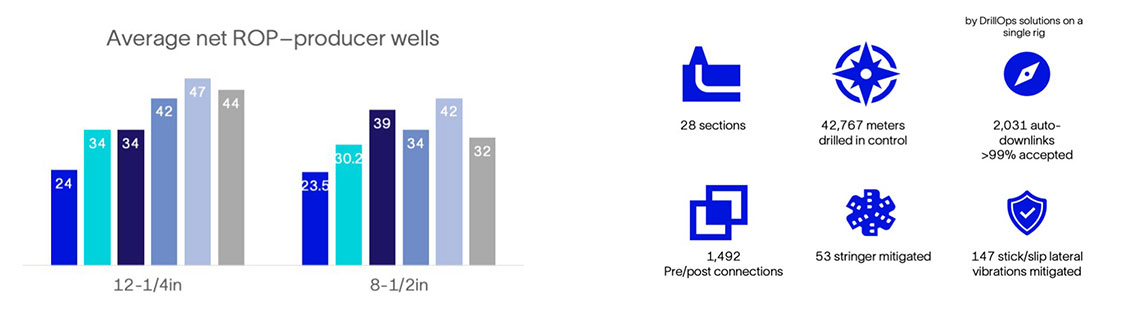

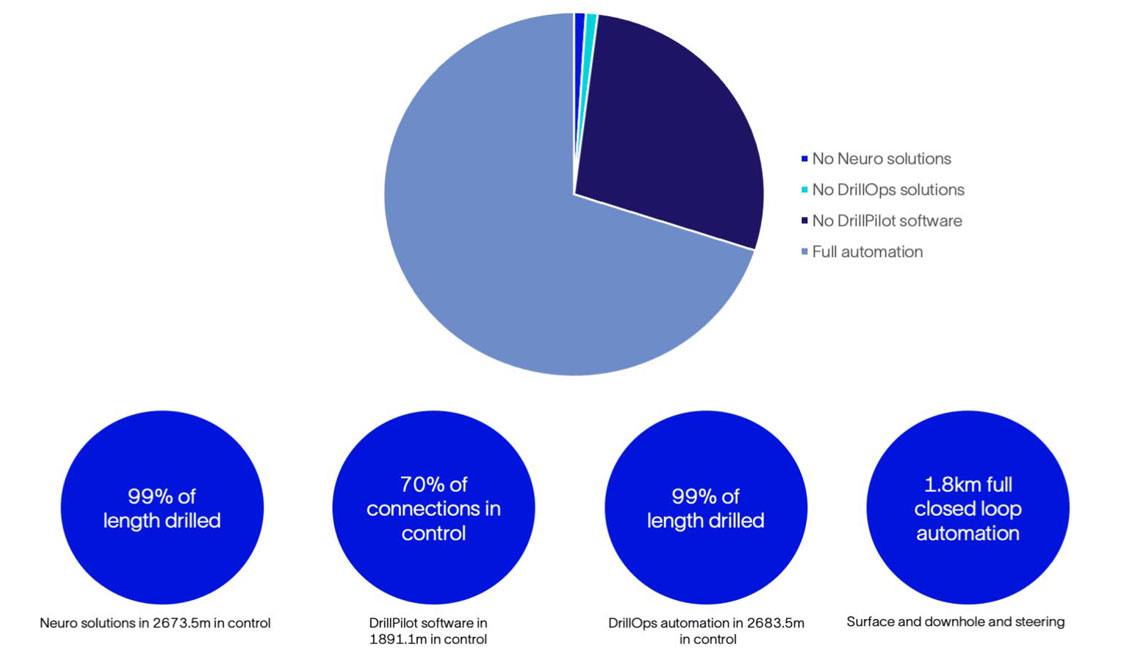

In the execution of this project on Equinor's Peregrino C platform multiple SLB technologies, including DrillOps solutions and Neuro™ autonomous directional drilling, were employed to enable 99% of a 2,695.5 m section to be drilled in autonomous control mode, and with a record 1,100 m drilled in 24 hours. DrillPilot™ equipment sequencing software was used to automate surface equipment and pipe handling and to complete sequence automation for connections and tripping, with 70% of connections ultimately performed using automation in DrillPilot software. On-bottom drilling performance was also optimized resulting in an increase of ROP from 75% to 95% when compared to the last short producer well drilled. Ultimately this project has resulted in safer more efficient well delivery while reducing costs and emissions.