Efficient drilling with superior control and a reduced environmental impact.

Advanced drilling system saves USD 206,000 and 3 days in Argentina

A major operator in Argentina working with SLB implemented the NeoSteer Max™ unconventional high-performance at-bit steerable system with autonomous downhole control features to drill the country’s longest lateral section and to overcome vibration and jamming in a high-density and high-solids mud environment. Drilling was completed in a single run with zero torque issues, avoiding a second trip to change out the BHA. As a result, the operator eliminated 3 days, saving USD 206,000.

The onshore formation required tackling torque jamming issues in a high-density and high-solids mud environment. The operator also had to manage additional challenges, such as handling temperatures up to 149 degC [300 degF] effectively. Additionally, the operator sought to drill the country’s longest lateral section in the formation.

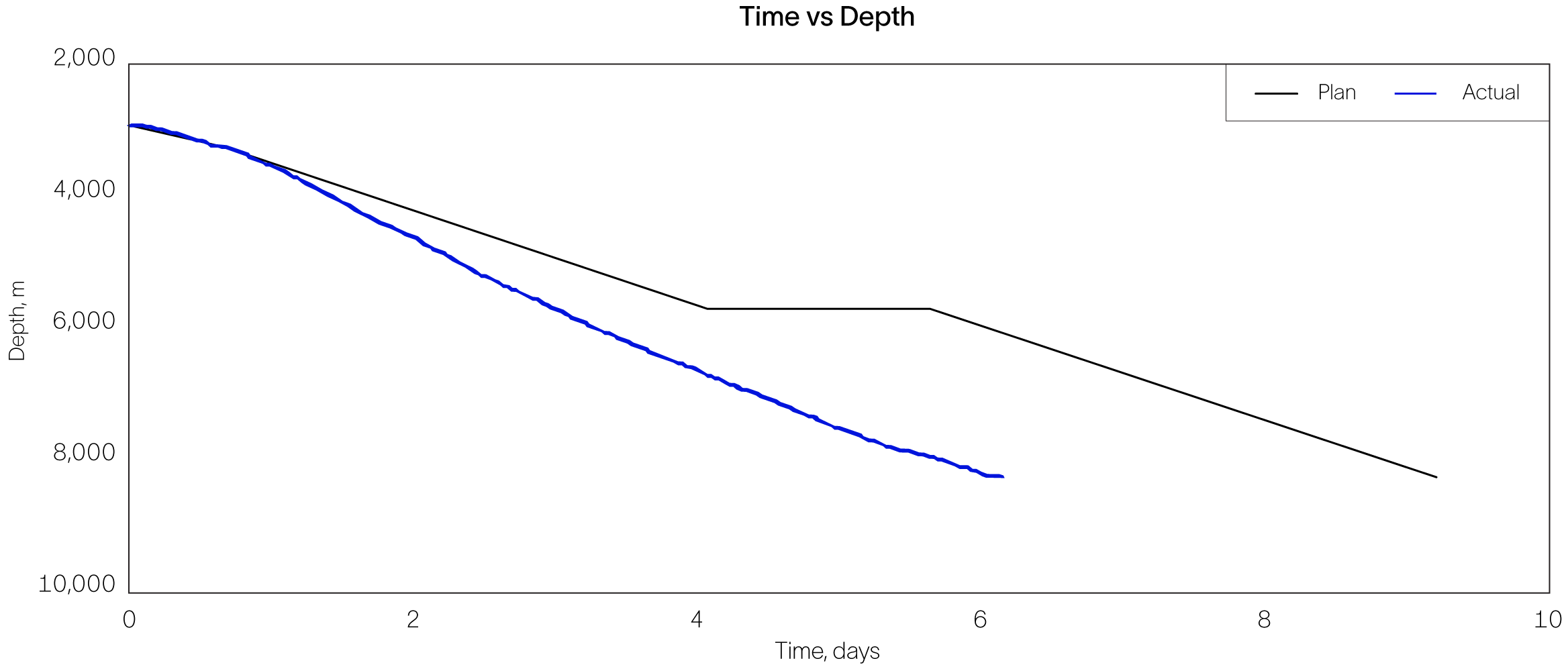

SLB recommended the NeoSteer Max unconventional high-performance ABSS with auto-curve and auto-tangent enhancements to boost reliability in high-density and high-solids mud environment. A drilling parameters road map was designed to optimize ROP and BHA integrity to reach 8,264-m TD. The crew drilled 5,342 m in 6 days, experiencing no jamming or torque issues despite a mud density of 14.7 lbm/galUS, and the high solids and debris content.

In addition to managing temperatures up to 149 degC [300 degF], the operator maintained excellent well trajectory control and experienced 100% real-time communication throughout the entire run. By improving efficiency in this high-density, high-solids environment, the country’s longest lateral section drilled in the formation, at 4,965 m, was achieved. With no NPT, the project saved an estimated USD 206,000.