Enable discipline experts to work together and make the best possible decisions from exploration to production.

Real-time, high-resolution imaging improves geosteering to place 428-m drain hole in zone

SLB exploited attic reserves in a carbonate field, drilling through target reservoir known to contain a complex fracture network and several faults.

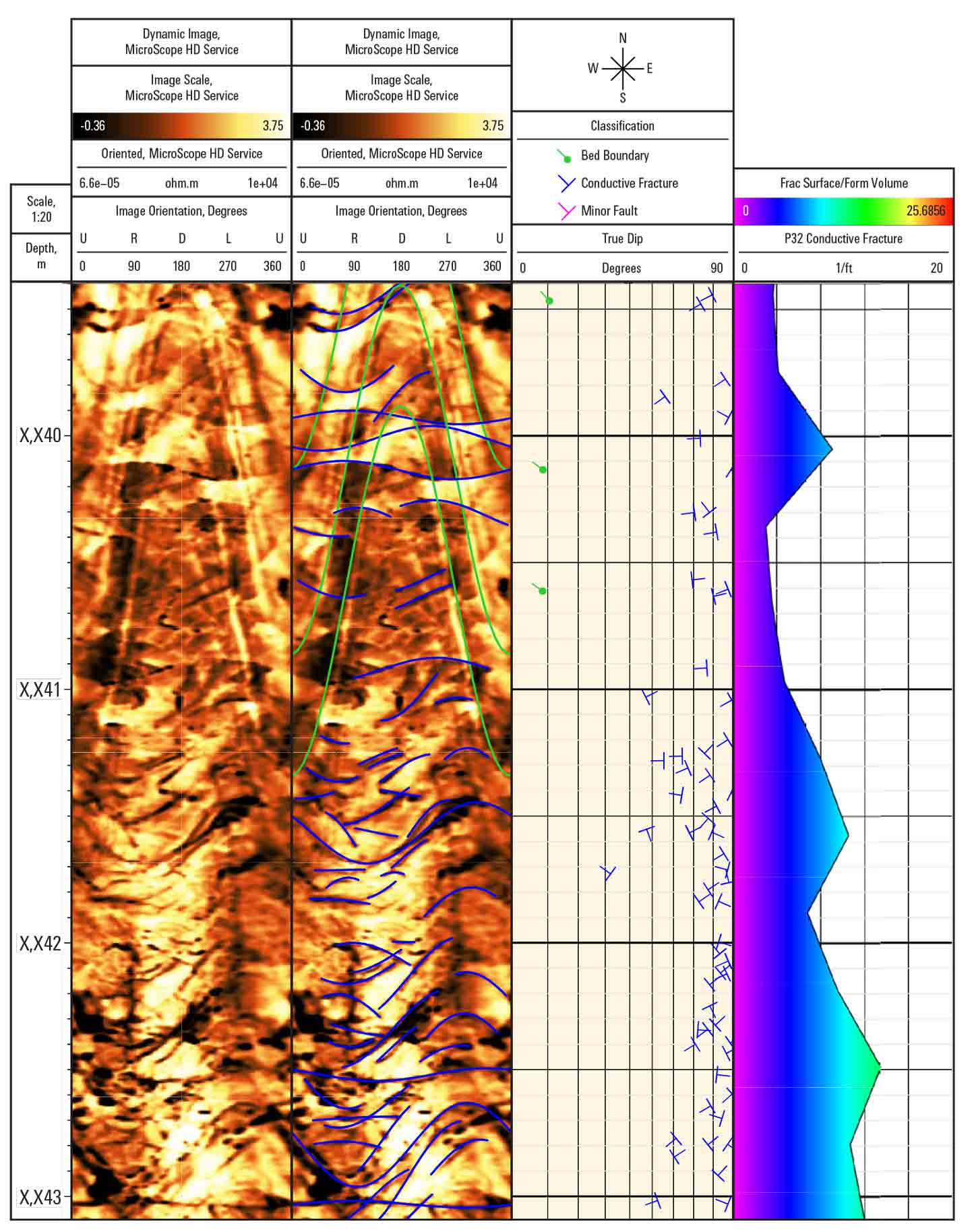

We used MicroScope HD™ high-definition imaging-while-drilling service and PeriScope™ bed boundary mapping service to geosteer a drain hole along the top of the target reservoir. We acquired high-resolution LWD images that characterized fracture networks to enhance geosteering as well as postjob analysis for completion design and structural interpretation.

Gain access to oil column in heavily fractured target reservoir

An energy company based in Italy had developed a challenging carbonate oil field. The operator planned to recover residual reserves by targeting a vuggy dolomite reservoir formation anticline, which was delimited by normal faults. The main objective of this operation was to increase production for the field with strategic well placement and completion design. The team decided to use advanced logging while drilling to ensure maximum exposure in the drain sections through water driven oil column.

The target formation was known to be intensively fractured and carsified in the lower portion, so the plan was to geosteer multiple drain holes immediately below the caprock to both access attic oil and distance the wellbores from oil-water contact.

Use LWD imaging and distance-to-boundary measurements to geosteer

SLB designed a BHA that would enable real-time characterization for geosteering and provide full directional control for precise well placement within the target. The BHA included MicroScope HD service to acquire real-time and recorded highresolution images and PeriScope service for distance-to-boundary measurements. This combination of technologies provided a detailed picture of the reservoir to guide geosteering along the caprock and identify troublesome fracture zones and faults that might interfere with the completion strategy.

These data were sent uphole using the ShortPulse™ integrated MWD platform and interpreted in real time using the Petrel™ E&P software platform. The fast interpretation gave the well placement team an accurate understanding of the downhole environment for directing the PowerDrive X6™ rotary steerable system along the path.

Placed 428 m of drain hole in zone, acquiring data at 90° inclination

The combination of LWD datasets from MicroScope HD and PeriScope services enabled SLB to geosteer 428-m MD within the target zone, acquiring data at 90° inclination. The successful placement of the drain hole immediately below the caprock, through proactive geosteering, improved attic oil recovery and increased the distance from oil-water contact.

As expected, the well encountered several faults, and images from MicroScope HD service were used to successfully steer the well into the target reservoir zone. Recorded-mode images were also acquired for advanced postjob analysis to optimize completion design and perform detailed structural interpretation. It has been planned to deploy the MicroScope HD service in additional wells in similar fields.