Manage or shut off water and gas production with application-specific permeability modifiers, chemical blocks, or cements.

Rigless chemical water shutoff revives offshore well in Caspian Sea

Dragon Oil Turkmenistan Ltd successfully implemented a rigless chemical water shutoff solution to address water breakthrough in the Lam field, Cheleken block, Caspian Sea, restoring oil production and reducing water cut.

Dragon Oil Turkmenistan Ltd faced a significant challenge when their offshore well in the Lam field, Cheleken block, experienced a sudden water breakthrough from the A-sand formation. The water cut sharply rose to 100%, necessitating the well to be shut-in. The well's complex completion with stand-alone sand screens made the water shutoff intervention more challenging than common well completions.

The objective was to achieve better isolation in the annular space between the tubing and the liner, as well as between the screens and the casing, using high-yield-strength particulate gel. Additionally, the intervention aimed to deliver services without accidents, personnel injury, equipment damage, spills, or environmental impact. Traditional water shutoff methods would require a complex workover, completion change, or sidetracking, resulting in substantially higher operation time and cost.

A rigless chemical water control solution was used, eliminating the need for a workover rig. The solution involved temporarily isolating the long string with a nipple plug run on slickline, followed by an injectivity test with filtered seawater to confirm communication between the long string and the short string through the seal units of the long string. This ensured that fluid could be injected into the upper zone while keeping the treatment pressure less than the frac pressure.

A tailored formulation of the OrganoSEAL R™ rigid organic crosslinked gel system was bullheaded into the matrix (water layer) and coupled with AllSeal™ water and gas conformance service particulate gel for the tail-in stage. The low-viscosity treatment fluids enabled easy placement, while the post-injection shut-in period allowed the fluids to form a rigid gel.

A post-treatment injectivity test confirmed adequate isolation in the leaking seals area and some isolation in the rock matrix. The gel volume remaining inside the production string was cleaned out by jetting water using coiled tubing. The tubing above the plug was punched to allow oil inflow from the long string.

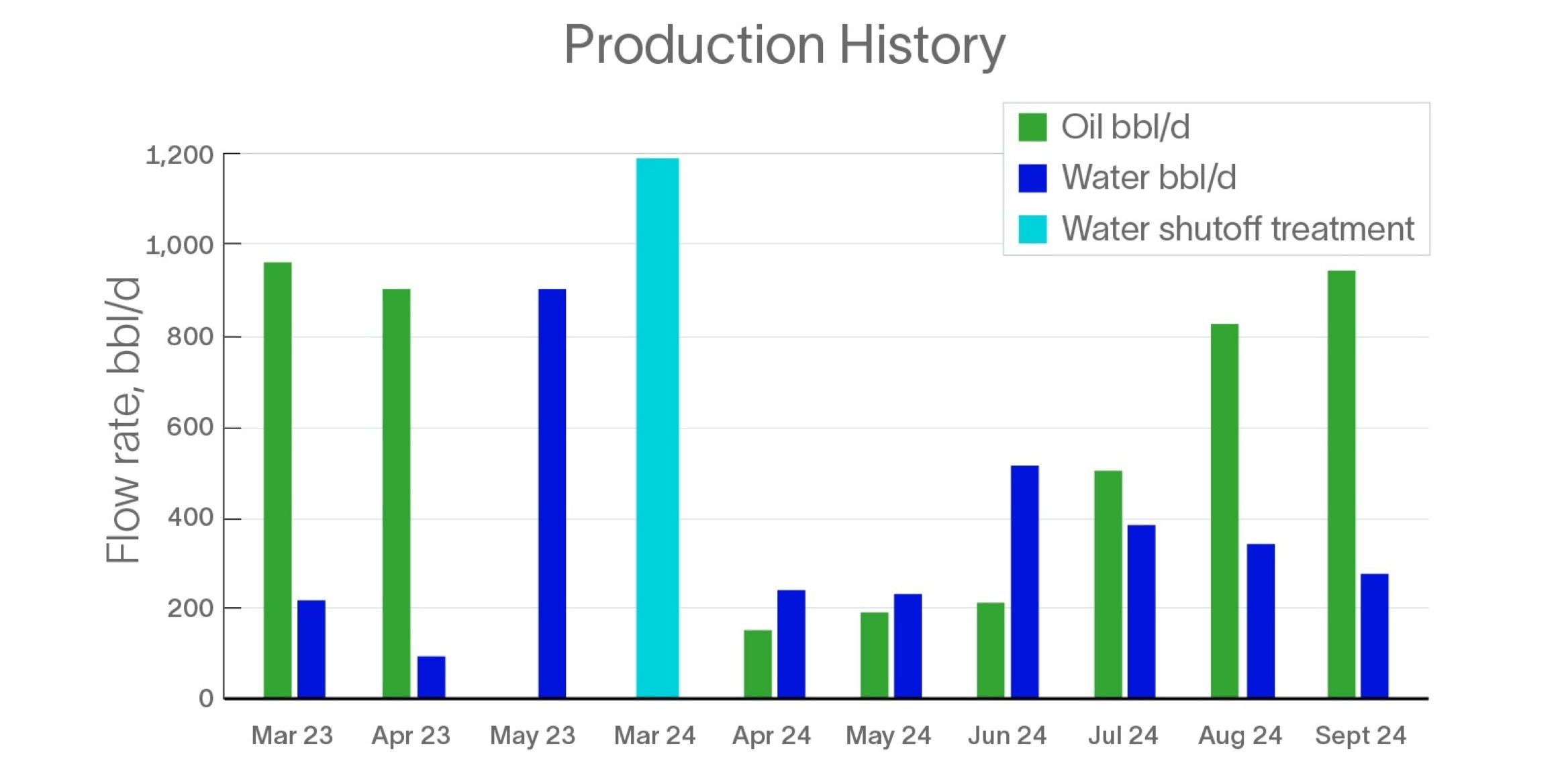

This approach provided the optimal technology for the conditions, quick execution, and a minimal footprint. It eliminated a costly well workover and resulted in minimal operation time. Post-treatment production flow rates demonstrated that the well was revived with approximately 150 bbl/d at the early stages, gradually increasing to around 940 bbl/d over six months. Water production declined to 270 bbl/d, close to its initial rate, and the well sustained similar performance 12 months post-treatment. The well shows no signs of production drops due to water cut more than 14 months after the treatment, demonstrating sustained performance and the effectiveness of the intervention.