BroadBand Shield

Constrains fracture growth with far-field diversion for optimized reservoir contact

Constrains fracture growth with far-field diversion for optimized reservoir contact

The Ordos Basin, located in north-central China, presents significant challenges because of its complex geological structure. The targeted formation, characterized by vertical and lateral heterogeneity, requires a geoengineered, integrated solution to mitigate risks and optimize oil recovery. The objective was to enhance reservoir recovery by characterizing reservoir quality, natural fractures, and completion quality using well, seismic, and fracturing data. This approach aimed to provide a customized fracturing job tailored to the local geology, addressing the challenges posed by natural fractures and subsurface heterogeneity.

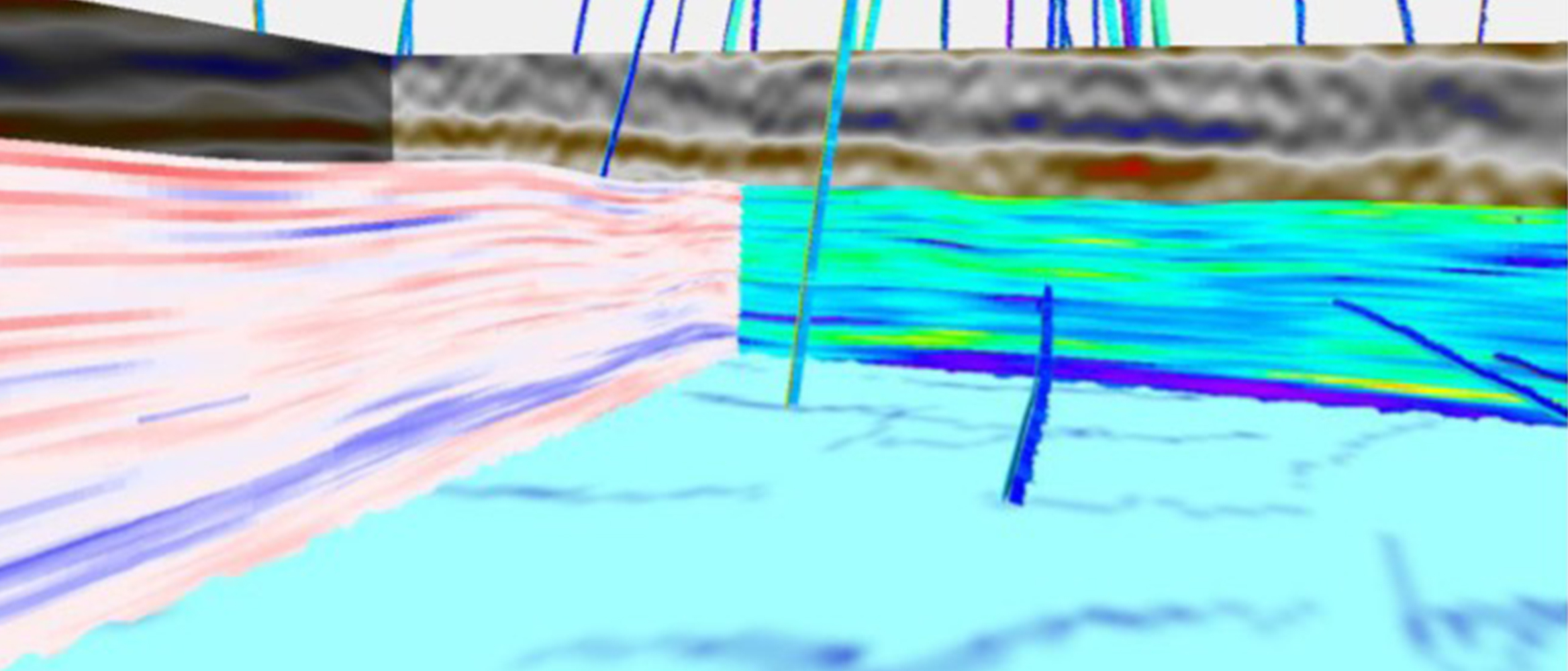

SLB employed its comprehensive Intelligent Stimulation workflows to tackle the challenges posed by the complex geological structure of the Ordos Basin. The project began with the construction of a 3D static Petrel™ subsurface software model, which integrated seismic data, core observations, petrophysics log data, and geomechanics interpretations. This model provided a detailed visualization of how reservoir properties varied both vertically and laterally across the targeted formation.

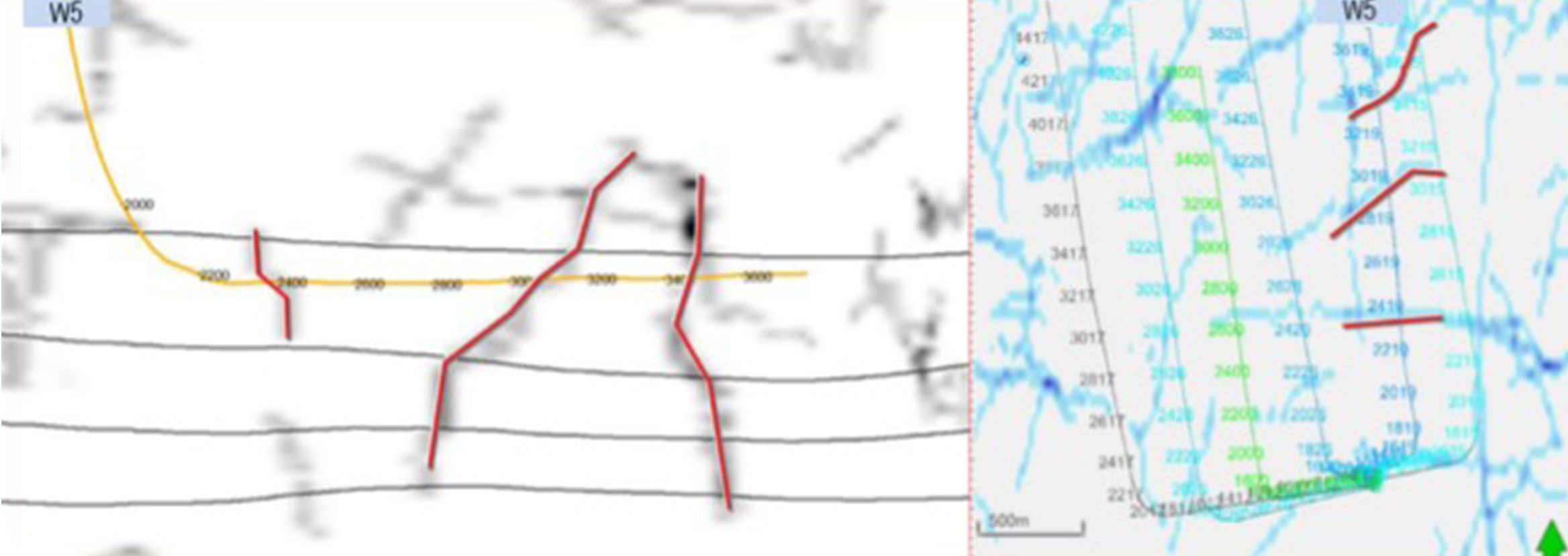

The static model served as the foundation for developing a dynamic Petrel model, which was crucial for designing the well pad. The dynamic model facilitated well planning by using historical production and pressure data for history matching and reservoir simulation. This step was essential for understanding reservoir drainage around the wellbore and optimizing well spacing to minimize interference and avoid overcapitalization.

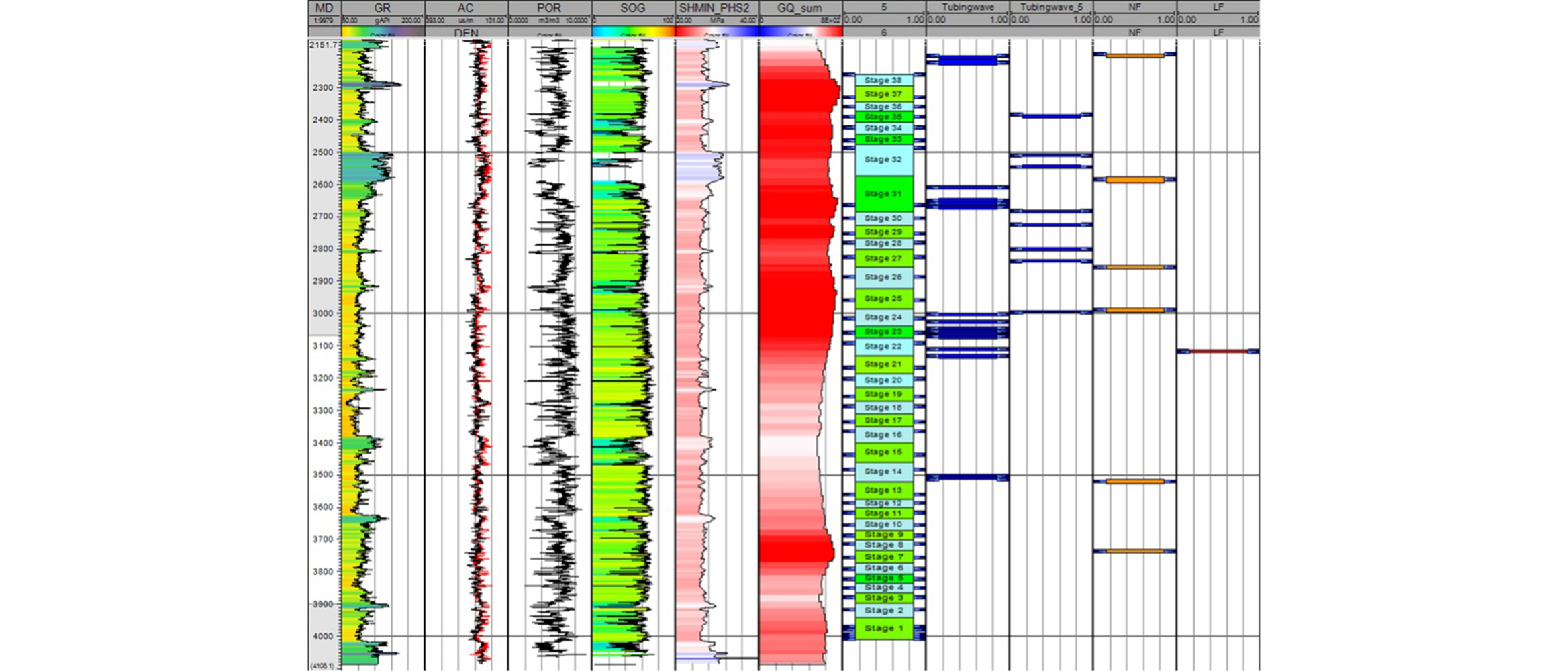

Intelligent Stimulation workflows were applied to integrate all available data, including well logs, core data, and seismic data, into the 3D geological Petrel model. A geomechanical model was then built in Kinetix™ reservoir-centric stimulation-to-production software and Petrel software, which included parameters such as porosity, permeability, saturations, lithology cube, Young's modulus, Poisson's ratio, brittleness, and stresses. This comprehensive modeling approach allowed for customized fracturing simulations and optimized treatments to maximize reservoir access and enhance estimated ultimate recovery through the application of BroadBand Sequence™ fracturing service and BroadBand Sheild™ fracture-geometry control service.

The fracturing design was tailored to each stage and well based on the geoscience models. Different strategies were applied, such as large-volume and high-rate fracturing to maintain long-term reservoir pressure, and intensive staging with low-volume and low-rate fracturing to improve near-wellbore flowing conditions. Technologies like BroadBand Shield service and BroadBand Sequence service were incorporated into the frac design, supported by WellWatcher Stim™ stimulation monitoring service for real-time fracture monitoring.

The Intelligent Stimulation workflows proved effective in optimizing fracturing treatments, reducing treatment scale around natural fractures, and enhancing production performance. Real-time adjustments during execution validated the geoengineering approach, resulting in a 20% production increase. Microseismic monitoring indicated that hydraulic fractures were influenced by natural fractures, improving the understanding and execution of hydraulic fracturing design. This comprehensive approach not only achieved high fracturing efficiency but also significantly impacted production performance, demonstrating the effectiveness of the SLB advanced fracturing techniques in unconventional shale reservoirs.

For more information, read SPE-217646-MS.