Petrel Advanced Completion Optimization

Using Intersect high-resolution reservoir simulator

Incorporates a workflow for reservoir-centric lower completion design and interval control valve optimization across well life.

The Gargaf reservoir, located in Libya’s Raguba field, is a sandstone formation with low reservoir quality and natural fractures, posing significant challenges for hydrocarbon extraction. SOC sought to overcome these challenges by fully characterizing the reservoir and integrating geological, petrophysical, and fracture data into a unified Petrel™ subsurface software model. The primary goal was to optimize stimulation workflows to enhance near-wellbore transmissibility, maximize reservoir contact, and improve hydrocarbon recovery.

Previous stimulation attempts had delivered suboptimal results, leaving the reservoir underperforming and prompting SOC to seek a more advanced and predictive approach. The development plan emphasized the use of cutting-edge modeling tools, such as Kinetix™ reservoir-centric stimulation-to-production software, to accurately predict fracture geometry and treatment efficiency. A two-stage stimulation strategy, combining the acid-based OneSTEP EF solution with conventional hydraulic fracturing, was identified as the key to unlocking the reservoir’s potential.

The ultimate objective was to validate stimulation effectiveness through well testing and production monitoring, scale successful designs across multiple wells, and integrate continuous performance feedback into the Petrel software for long-term field development.

In 2024, SLB worked with SOC to implement the Intelligent Stimulation approach in the Gargaf reservoir. The first step involved consolidating all postdrilling, workover, and stimulation data. The reservoir information was fed into Petrel software, enabling precise modeling of reservoir behavior. This integration improved decision-making efficiency and provided a robust foundation for designing optimized stimulation workflows.

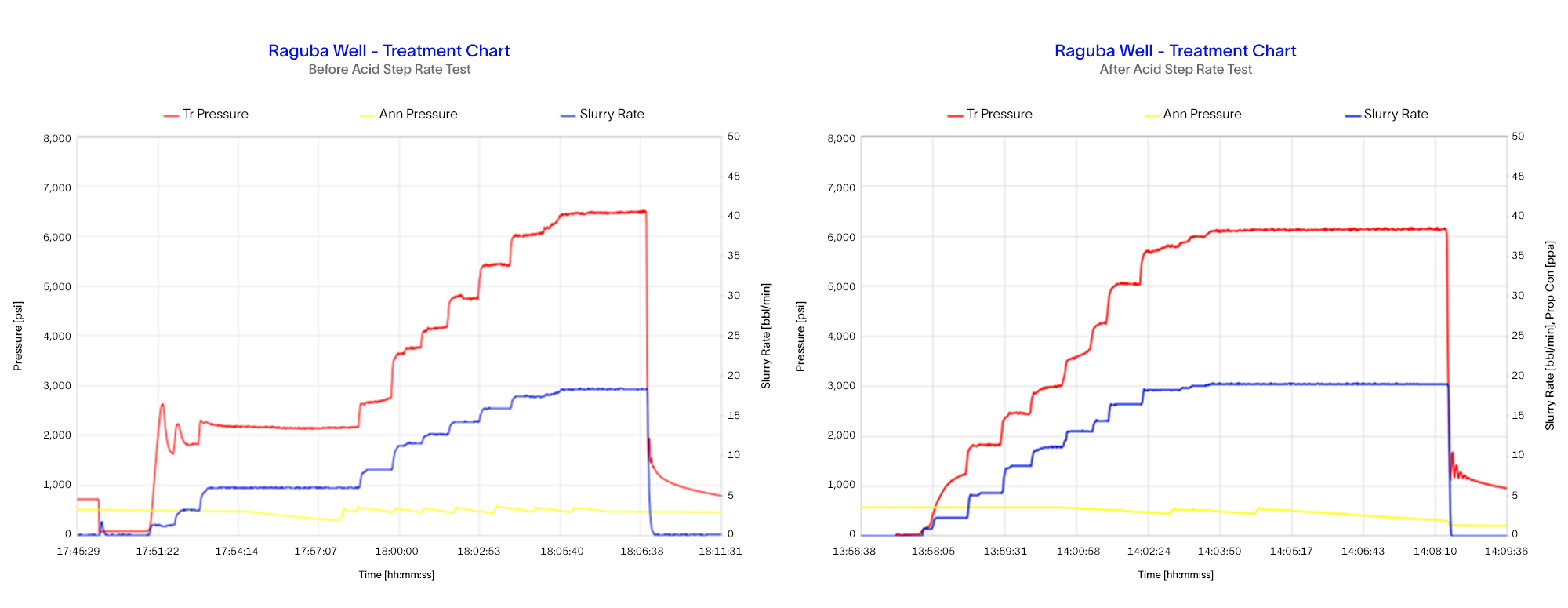

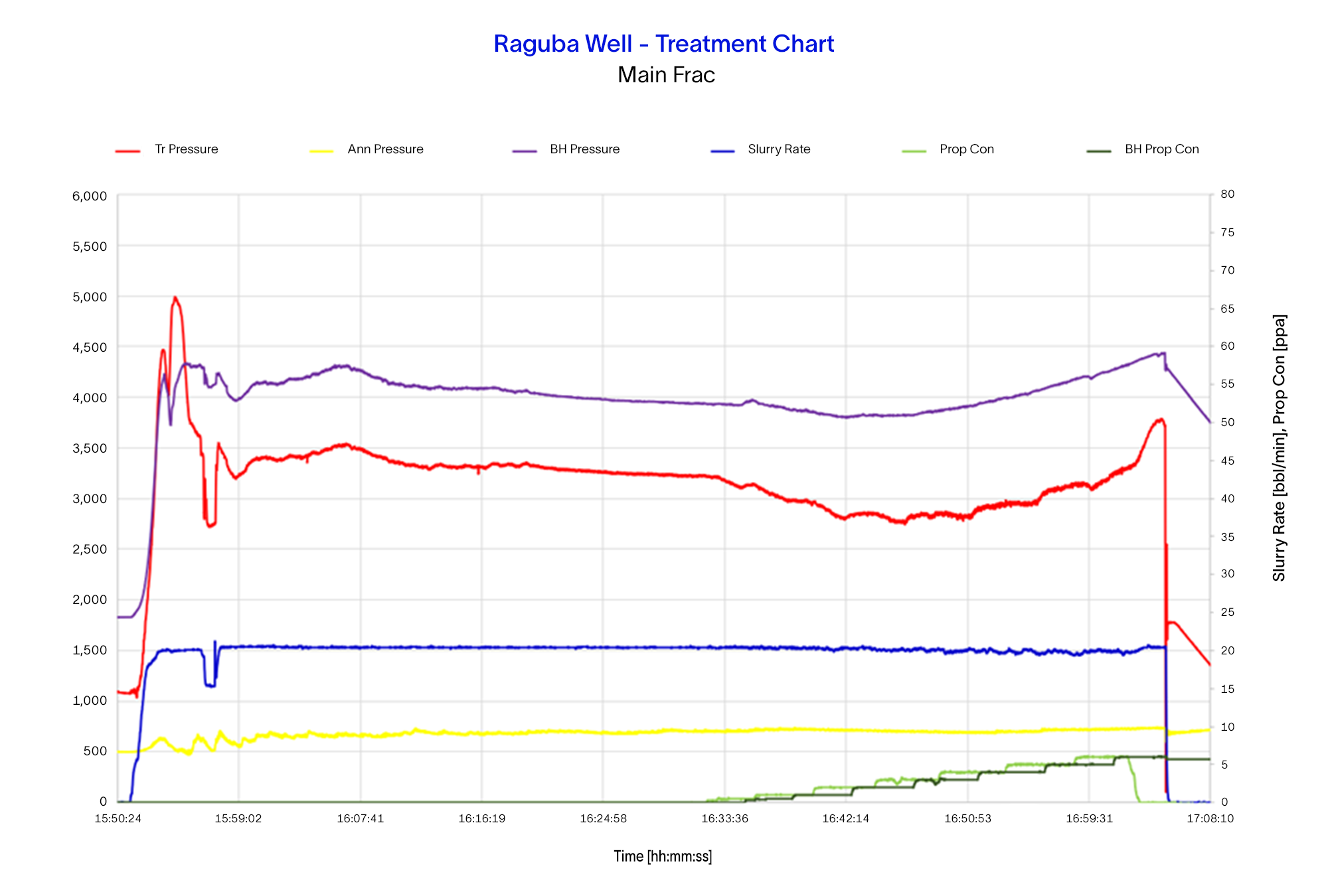

The two-stage stimulation approach began with the application of the OneSTEP EF solution, a single-step sandstone acid treatment designed to enhance near-wellbore transmissibility by dissolving formation damage and improving flow paths. This was followed by conventional hydraulic fracturing to maximize reservoir contact and improve hydrocarbon flow. Kinetix software was used to predict fracture geometry and optimize treatment designs, ensuring maximum efficiency and effectiveness.

The results were remarkable. Production increased to 850 bbl/d and 8 MMscf/d with 8% water cut, while wellhead pressure rose from 0 psi to 1,300 psi. Encouraged by this success, SOC applied the same technique to five additional wells in December 2024, achieving an average crude oil production of 900 bbl/d per well.This success validated the effectiveness of the Intelligent Stimulation strategy and demonstrated the value of integrating advanced modeling tools into field development workflows. By scaling the approach across multiple wells, SOC enhanced reservoir drainage and hydrocarbon recovery, setting the stage for long-term, technically robust field development.