Drill more quickly and accurately in harsh unconventional formations and conditions.

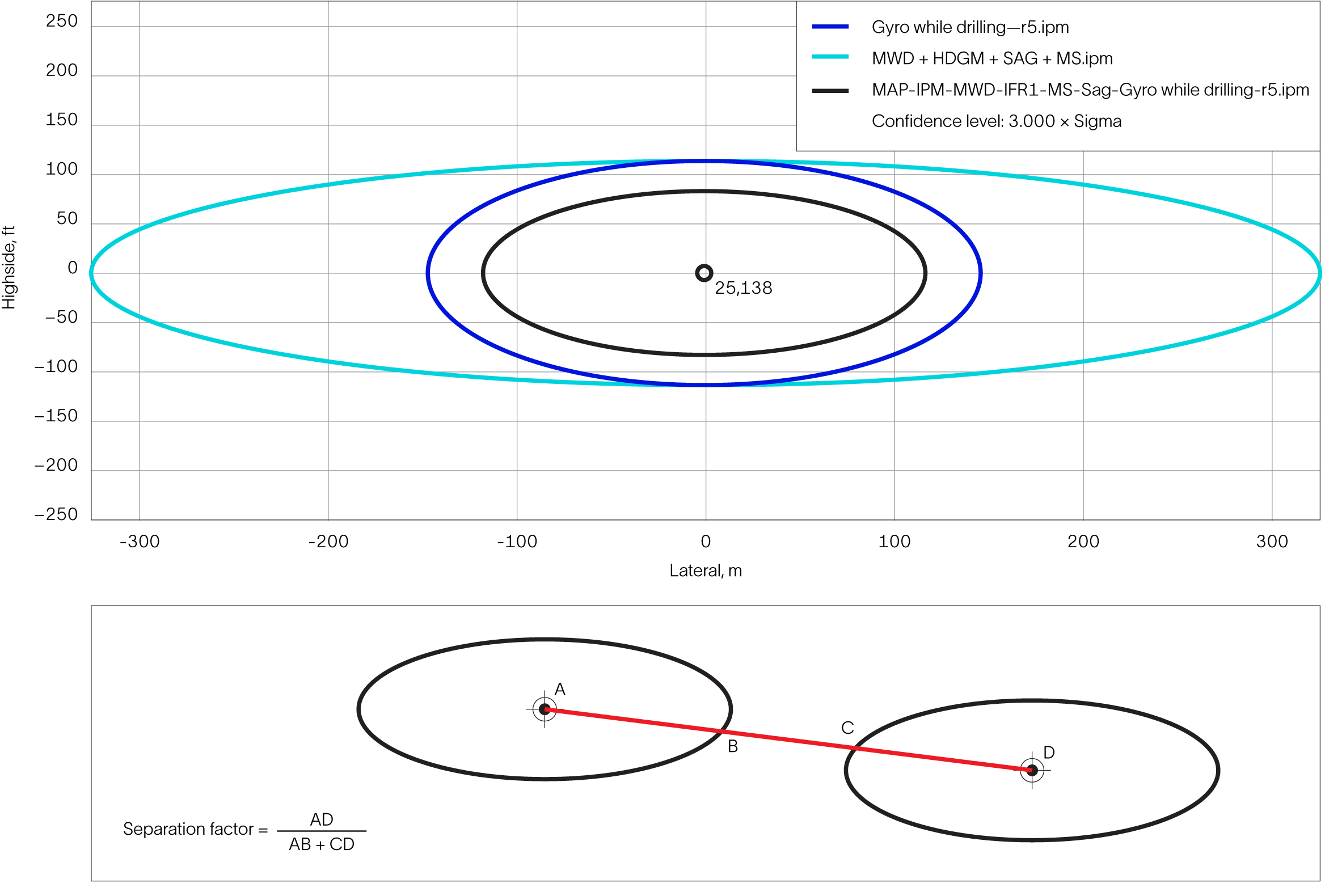

Unconventional dual MWD and gyro service with advanced error modeling delivers 30% improvement in the separation factor

In the Permian Basin, SLB deployed the TruMax Gyro™ unconventional dual MWD and gyro service, incorporating an advanced error modeling approach that resulted in a 30% improvement in the separation factor within a complex pad drilling scenario. This solution enabled more aggressive well spacing for the customer while minimizing collision risk, thereby increasing well inventory and enhancing drilling safety.

The customer aimed to increase lateral well density within a tight pad drilling environment in the Permian Basin. However, the close proximity of the laterals introduced risks of wellbore collisions and steering errors, primarily due to degraded survey accuracy in high magnetic interference zones. Existing MWD systems struggled to provide reliable azimuth control, and traditional survey models were insufficient for confidently assessing well separation. As a result, a new solution was needed to overcome these limitations.

SLB proposed the TruMax Gyro service with an advanced error modeling approach. This solution achieved a measurable improvement in the separation factor—greater than 30% in modeled scenarios—enabling the drilling of additional laterals within the same pad and boosting overall production potential. It provided real-time assurance for directional drilling teams, improving well placement quality, and reducing the risk of costly collision events and unnecessary sidetrack. Additionally, it validated gyro while drilling (GWD) as a critical enabler in the customer’s aggressive well spacing strategy.