Accelerate well construction and optimize performance.

Integrated Well Construction

Published: 01/01/2005

Integrated Well Construction

Published: 01/01/2005

Joint venture

Schlumberger Integrated Project Management (IPM) designed, engineered, and executed the initial work program for two exploration wells under a fully integrated contract in Algeria. IPM was selected by a joint venture group—that had never operated in Algeria—to leverage Schlumberger's extensive local experience and fast track the group's entry into the country.

The contract was awarded in 2003 and, in addition to the 2 exploration wells, the work scope included 20 km of access roads, an airstrip, and a water well.

The contract model improved cost and risk factors for key components of the program. The joint venture group could work with Schlumberger IPM as a single lead contractor while maintaining ultimate control over the operation. Schlumberger was able to use its extensive company and segment infrastructure and experience in country to design, engineer, and execute the program.

This was a major cost and time saving to the joint venture because it would not need a large technical and management team or a logistics support base. Using Schlumberger IPM, the client was able to defer significant mobilization and expenditure decisions until the results of the first exploration program were known.

Planning and engineering

Schlumberger IPM used its expertise to meet two key challenges in the program: The first was to overcome problems related to the hardness of the rock that would be encountered while drilling the reservoir section, and the second was to design and implement a reservoir evaluation solution that enabled the optimum identification of hydrocarbon-bearing zones.

The engineering planning took place in parallel with the procurement of tangibles and focused on achieving zero failures using the Integrated Project Management System.

Peer reviews and offset well analysis ensured optimum well design, and workshops with multidisciplinary field and operations staff from all Schlumberger technology segments identified the best-in-class techniques that would be needed to succeed.

Technical challenges

A geomechanics and rock strength analysis (RSA) performed before drilling identified an extremely hard formation. With the RSA, the Schlumberger team developed a drilling strategy that minimized slow drilling times while ensuring borehole stability and trajectory.

One of the main challenges during the drilling phase was the use of water-base mud. A potassium chloride–polymer system—combined with proven engineering procedures—provided good hole-stability characteristics.

Results

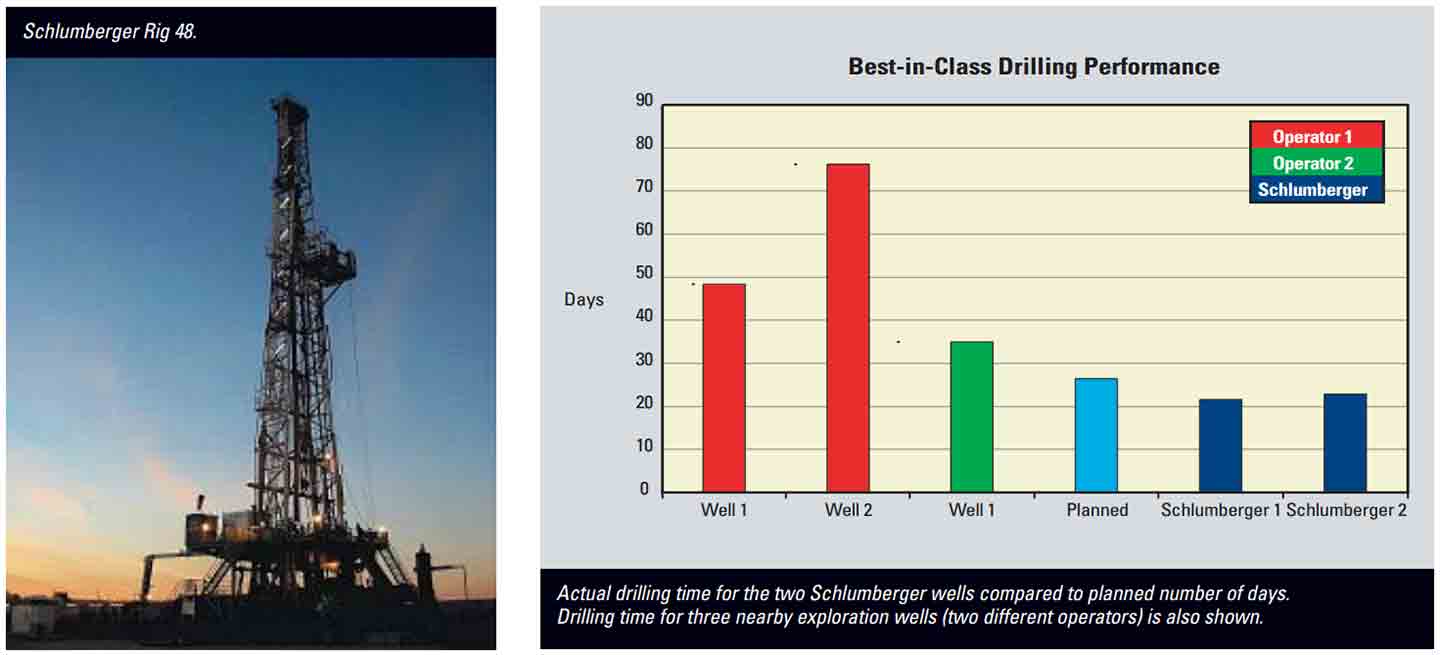

The planned drilling curve was aggressive, compared to those of offset wells, but the Schlumberger team thought it was possible with new techniques. The first well was completed 4 days ahead of schedule. The second well was completed in the planned time, even with additional drilling and logging requested by the client in response to evaluation results.

The 1,500-hp Schlumberger Rig 48, used for the drilling, worked without a lost time incident during the full campaign, and rig downtime accounted for a nonproductive time (NPT) of less than 2%. The total NPT for the project was approximately 7%.

Technology solutions

The IPM team assisted the client in selecting fit-for-purpose solutions to meet the key exploration objectives.

The LiteCRETE lightweight cement slurry system permitted the 9 5/8-in casing string to be cemented in a single operation.

The wells were drilled in an area where changes in water salinity made conventional log interpretation difficult. The initial data acquisition program was adapted to include more advanced logging technology to better evaluate the formation.

FMI fullbore formation microimager data showed an Ordovician oil zone with extremely low permeability to be naturally fractured. As a result, the client requested an alternative liner configuration, which was quickly designed and successfully implemented. This solution avoided cementing the natural fractures in one reservoir zone but still allowed isolating other reservoir zones that were higher up in the wellbore. Results from well tests proved the success of this approach.

Value creation

The MRF magnetic resonance fluid characterization method, using data from the CMR combinable magnetic resonance tool's log, identified hydrocarbon-bearing zones (Devonian) that would have been previously interpreted as water bearing using conventional logging technology. The recognition of these new potential target zones has increased the commercial viability of the asset.

Challenge: A geomechanics and rock strength analysis (RSA) performed before drilling identified an extremely hard formation. With the RSA, the Schlumberger team developed a drilling strategy that minimized slow drilling times while ensuring borehole stability and trajectory.

One of the main challenges during the drilling phase was the use of water-base mud. A potassium chloride–polymer system—combined with proven engineering procedures—provided good hole-stability characteristics.

Solution: The IPM team assisted the client in selecting fit-for-purpose solutions to meet the key exploration objectives.

The LiteCRETE lightweight cement slurry system permitted the 9 5/8-in casing string to be cemented in a single operation.

The wells were drilled in an area where changes in water salinity made conventional log interpretation difficult. The initial data acquisition program was adapted to include more advanced logging technology to better evaluate the formation.

Results: FMI fullbore formation microimager data showed an Ordovician oil zone with extremely low permeability to be naturally fractured. As a result, the client requested an alternative liner configuration, which was quickly designed and successfully implemented. This solution avoided cementing the natural fractures in one reservoir zone but still allowed isolating other reservoir zones that were higher up in the wellbore. Results from well tests proved the success of this approach.