Historically, lithium production has relied on resource-intensive processes, such as hard rock mining or brine evaporation ponds, both of which can lead to significant land disturbance, water consumption, and carbon emissions. The energy industry is now responding by undergoing a transformative shift—one that centers around improving our understanding of the subsurface and integrating multiple parts of the process. The goal? To extract more lithium with less emissions.

The subsurface: Ground zero for lithium’s future

Beneath the earth's surface lies a complex network of geological formations that host lithium-rich brines. These brines are often found in sedimentary basins or geothermal reservoirs, trapped within the pore spaces of permeable rocks. Unlocking their potential requires more than just drilling wells; it requires a system-level understanding of the geological, hydrological, and chemical processes that have shaped these formations over millions of years.

Lithium extraction from brine reservoirs hinges on four critical subsurface elements:

- Source—The original geochemical processes (driven by heat, pressure, and water-rock interactions) that generate lithium-enriched fluids.

- Trap—The structural or stratigraphic configurations that isolate and concentrate the brine within the reservoir.

- Migration pathways—Fractures, faults, and porous media through which lithium-rich fluids travel from the source zones to accumulation areas.

- Reservoir properties—Physical and chemical traits such as porosity, permeability, temperature, pressure, and fluid composition that govern brine flow and resource accessibility.

Understanding this geosystem forms the basis for developing a more responsible, long-term production strategy. And it’s the insights gathered during this exploration that underpin a more holistic, well-to-product approach.

The role of integrated subsurface modeling in fully optimized operations

Integrating advanced subsurface models in the planning and execution of your lithium extraction and production enables the full optimization of your processes, which means more efficiency and less undesirable impact on the environment. It’s a modern approach that combines the characterization of what’s underneath the surface with comprehensive processing workflows above the surface to ensure that every stage of the extraction process—from brine pretreatment to lithium salt crystallization—reaches its full potential.

But what does this level of lithium extraction look like? What does it take to achieve an integrated approach that spans from direct lithium extraction (DLE) technologies through a full value chain of efficiency, all the way to lithium extraction?

Let’s consider a hypothetical lithium production facility aiming to produce 10,000 metric tons of lithium carbonate equivalent per year for 20 years, yielding a total production of 200,000 tons. With a brine lithium concentration of 200 milligrams per liter, this operation would require the extraction of around 5,300 gallons per minute, equivalent to nearly 180,000 barrels per day or 1.3 billion barrels over two decades.

Managing this volume responsibly involves more than just well construction. It requires:

- Carefully monitoring of the reservoir for changes in pressure as fluids are withdrawn.

- Adopting brine reinjection strategies that avoid dilution or the cross-contamination of lithium-rich zones.

- Employing dynamic reservoir models that continuously forecast production rates and geochemical responses to ensure long-term performance.

Once paired with robust subsurface planning, DLE can dramatically reduce the environmental and societal costs traditionally associated with lithium mining. This shift aligns closely with the United Nations Sustainable Development Goals (particularly those related to clean energy, responsible consumption, and climate action) by bringing benefits such as:

- Water resource protection—By reinjecting processed brine, DLE preserves aquifer pressure and mitigates freshwater depletion.

- Smaller footprint—Modular DLE systems occupy a fraction of the land used by evaporation ponds, thereby minimizing ecosystem disruption.

- Lower emissions—Energy-efficient tech reduces the carbon footprint of lithium production.

- Improved community engagement—Transparent, science-based extraction fosters trust with local communities and regulatory bodies.

Leveraging the power of data from exploration to extraction

Data is fundamental to subsurface enablement. Integrating multidisciplinary datasets—geological, geophysical, geochemical, and petrophysical—provides a holistic view of your reservoir’s structure, behavior, and economic potential.

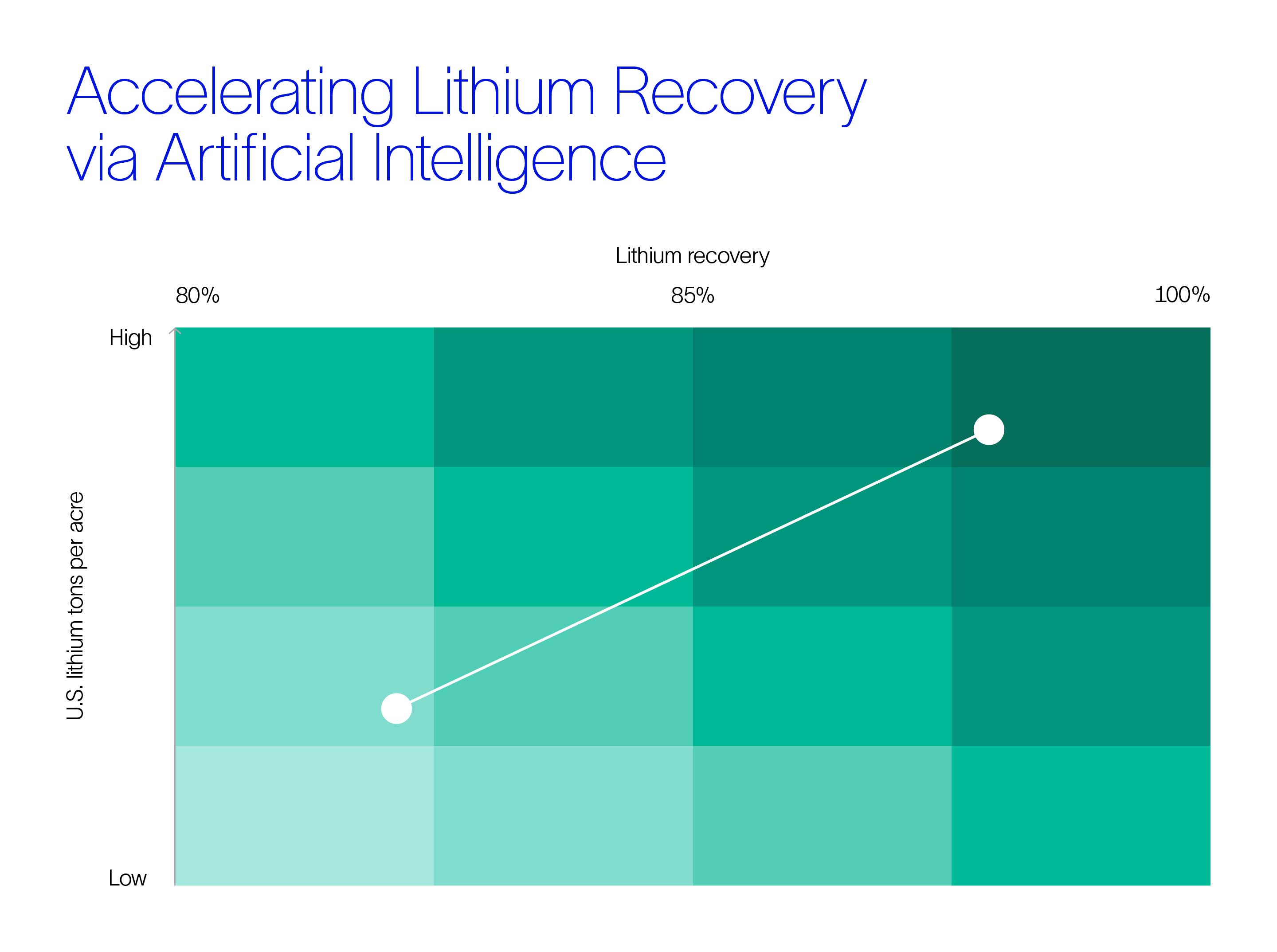

Artificial intelligence (AI) is increasingly being used to enhance geological modeling by automating the interpretation of complex subsurface data. According to the IEA’s Global Critical Minerals Outlook 2025, AI tools can rapidly process seismic, geochemical, and geophysical datasets to identify promising lithium-bearing formations with greater accuracy. These models not only reduce the time and cost of exploration but also improve the precision of resource estimates, helping operators make better informed decisions about where and how to drill. This is especially valuable in underexplored regions, where traditional methods may be too slow or costly to deploy effectively.

Despite its potential, building high-quality predictive models remains a challenge due to limited data availability—the result of a legacy of historical practices and budget constraints in the mining sector. AI and machine learning (ML) are helping bridge this gap by uncovering both linear and nonlinear relationships within complex datasets. Techniques such as ensemble learning (e.g., random forests, gradient boosting) reveal previously hidden geochemical patterns, thereby reducing uncertainty and enhancing confidence in subsurface models.

For example, automated petrophysical analysis can streamline workflows by using advanced outlier detection and reconstruction to perform quality control on legacy log data, classify electro-facies across large datasets, and rapidly interpret lithology, grain density, and porosity.

Similarly, AI-driven well architecture optimization enables you to identify high-potential zones through large-scale data interpretation, reduce exploratory drilling requirements, minimize environmental impact while improving discovery rates, and enhance your evaluation of known sites for future development.

These innovations aren’t just technological upgrades; they represent a paradigm shift in how industry players approach lithium exploration and development.

Derisking lithium production through integrated modeling

Successfully developing lithium resources requires more than just identifying promising reservoirs—it demands a data-driven approach that spans the entire project life cycle. For this reason, integrated modeling frameworks are emerging as essential tools for reducing uncertainty, optimizing resource recovery, and ensuring long-term sustainability.

By combining basin analysis, static and dynamic reservoir modeling, and aqueous flow simulations, operators can better understand subsurface behavior, forecast production performance, and design more efficient extraction and reinjection strategies.

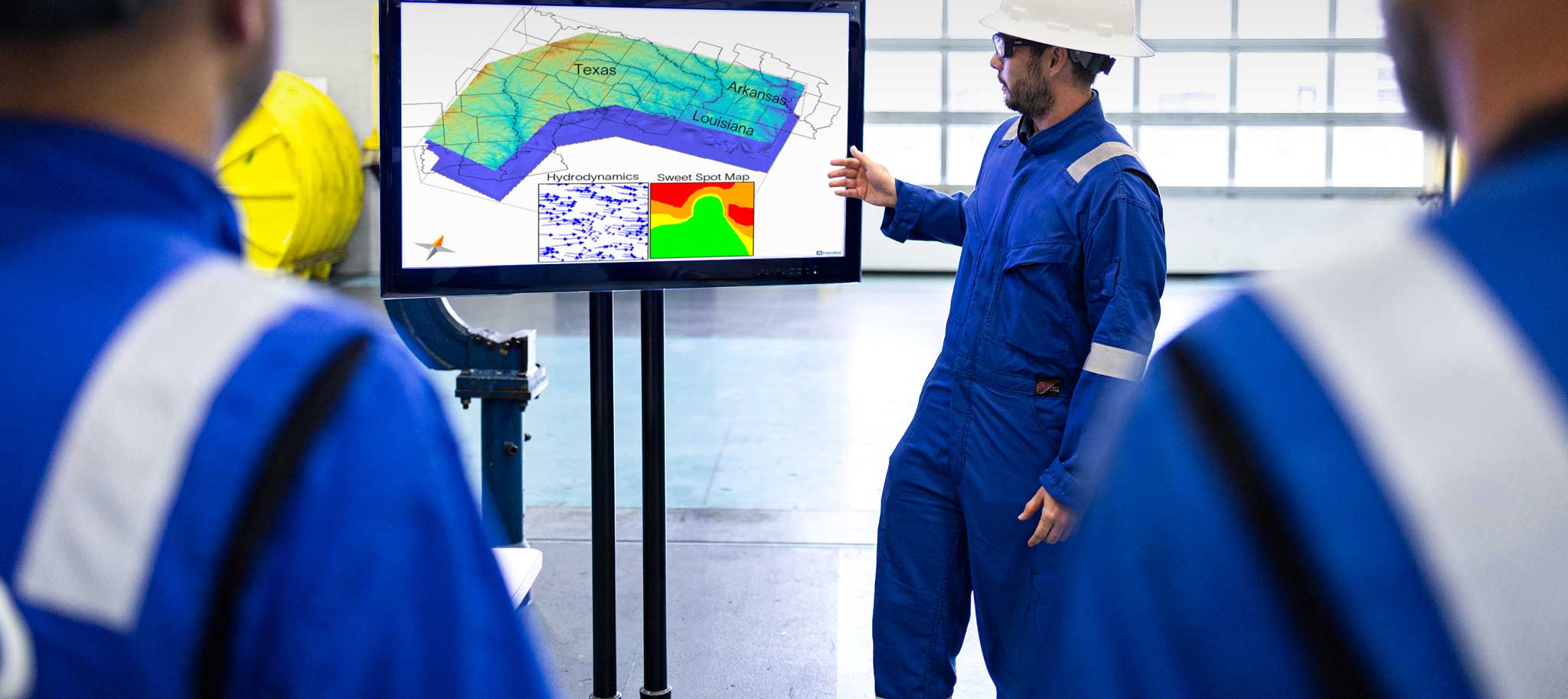

- Basin modeling—Reconstructs geological evolution and identifies favorable zones for lithium accumulation. Three key objectives are:

- Sweet spot map

- Identification of lithium source

- Hydrodynamics of brine flow paths.

- Static reservoir modeling—Builds a 3D framework of rock properties and fluid distributions, along with estimating the lithium resource in place. Three key objectives are:

- Multiphysics approach integrating various data

- Multiphysics and petrophysics using machine learning

- Connectivity, sensitivity, and uncertainty analysis.

- Aqueous flow modeling: Helps you understand—thanks to AI and ML—the highest deliverability in the acreage using the lithium quality index (LQI) approach. Three key objectives are:

- Relative LQI heat map

- Optimizing the location for dynamic modeling

- Identifying the best acreage for meeting the project size.

- Dynamic reservoir simulation: Predicts how lithium-rich fluids will move during production, how pressure changes impact recovery, and where reinjection will be most effective. Three key objectives are:

- Full simulation for expected DLE production lifetime

- Concept selection and plan effluent reinjection management

- Reserves to be produced (tons) over desired time.

These models not only support technical and economic decision making but also help align projects with environmental and regulatory expectations. Not to mention they support compliance with international reporting standards such as NI 43-101 in Canada, the JORC Code in Australia, and S-K 1300 in the US, ensuring that investors and regulators receive credible and transparent resource evaluations.

Bridging basin, static, and dynamic models to optimize production

Advanced 3D basin models combine:

- Geophysical and seismic data for structural interpretation

- Geological logs and core samples for lithofacies analysis

- Porosity and permeability maps for fluid flow prediction

- Temperature and geochemical data for understanding lithium distribution and brine evolution.

These models are crucial for delineating reservoir boundaries, identifying sweet spots, and assessing reinjection zones. By simulating subsurface dynamics across time and space, operators can reduce drilling risk, optimize well placement, and avoid production bottlenecks.

As stated earlier, a static model estimates the volume and distribution of fluids in place, but more importantly with seismic inversion and well tie-ins, it also helps operators understand the heterogeneity and connectivity of their reservoirs. A good static model is essential for building a good dynamic model, and dynamic models are pivotal to achieving any kind of technical, economic, and environmental goals related to lithium extraction.

Dynamic models are particularly critical in:

- Predicting brine flow—Understanding how fluids move helps prevent early breakthroughs, loss of lithium-rich zones, or reservoir damage.

- Designing sustainable operations—Proper reinjection strategies maintain reservoir pressure and integrity.

- Reducing capital risk—Dynamic modeling reduces the likelihood of drilling nonproductive wells or overcapitalizing infrastructure.

- Managing lithium concentration—As brine is extracted and processed, maintaining the natural concentration of lithium becomes increasingly challenging due to fluid movement, pressure changes, and reinjection dynamics. These models allow for the strategic placement of production and injection wells, the optimization of flow rates, and the design of reinjection strategies that minimize disruption to high-grade zones and help plan a constant brine feed over decades.

This type of modeling is a core enabler of precision lithium extraction—a concept borrowed from oil and gas but adapted for critical mineral recovery.

Quantifiable gains: The impact of subsurface enablement

Successful implementation of subsurface workflows has tangible benefits. In real-world applications, projects that employ advanced modeling report a 20-30% improvement in extraction efficiency, significant reductions in water use and energy consumption, and longer project lifespans with lower operational costs.

For instance, a well-managed DLE project might recover lithium from a brine stream with 85% reinjection efficiency, maintaining concentration and pressure while reducing waste. These improvements are not theoretical; they mirror proven performance in the oilfield and geothermal industries, where subsurface management has been refined for several decades.

A path forward for responsible lithium

The subsurface is the foundation upon which a more sustainable solution to lithium extraction must be built. By investing in geological understanding, embracing DLE technologies, and implementing advanced modeling tools, the industry can move beyond the trade-offs of the past.

This approach empowers stakeholders to scale lithium production without sacrificing environmental integrity or social license. It creates a blueprint for balancing economic opportunity with ecological responsibility, something the energy transition desperately needs.

In the race to electrify the world, responsible resource extraction and reinjection aren’t optional; they’re essential. And with today’s advanced software, robust modeling workflows, and decades of subsurface expertise at our disposal, it’s not only an opportunity but an obligation to lead with accountability.