AxeBlade

Ridged diamond element bit

Improve penetration rates and downhole control with our ridged 3D cutting element bit.

Published: 11/16/2017

Published: 11/16/2017

Today, approximately 90% of the footage drilled around the world is drilled by a PDC bit. The flat, cylindrical PDC cutter shape produces a shearing action, which is not ideal for every different formation that we’re drilling through. In many cases, the extreme wear and impact damage on the cutters require customers to use multiple PDC bits to drill a single section.

To solve this challenge, we began by designing durable cutting elements that enable our customers to drill entire sections with one bit, to really help reduce the amount of drilling time and cost for a well. It was in this effort that we saw an opportunity to use specialized shaped cutting elements to optimize performance above and beyond what can be done with a traditional PDC cutter’s flat cylindrical shape.

Right now, many customers are really pushing the length of the laterals that they’re drilling. As they increase the footage, drilling becomes more and more demanding, not only to the bit but even to some of the other downhole tools.

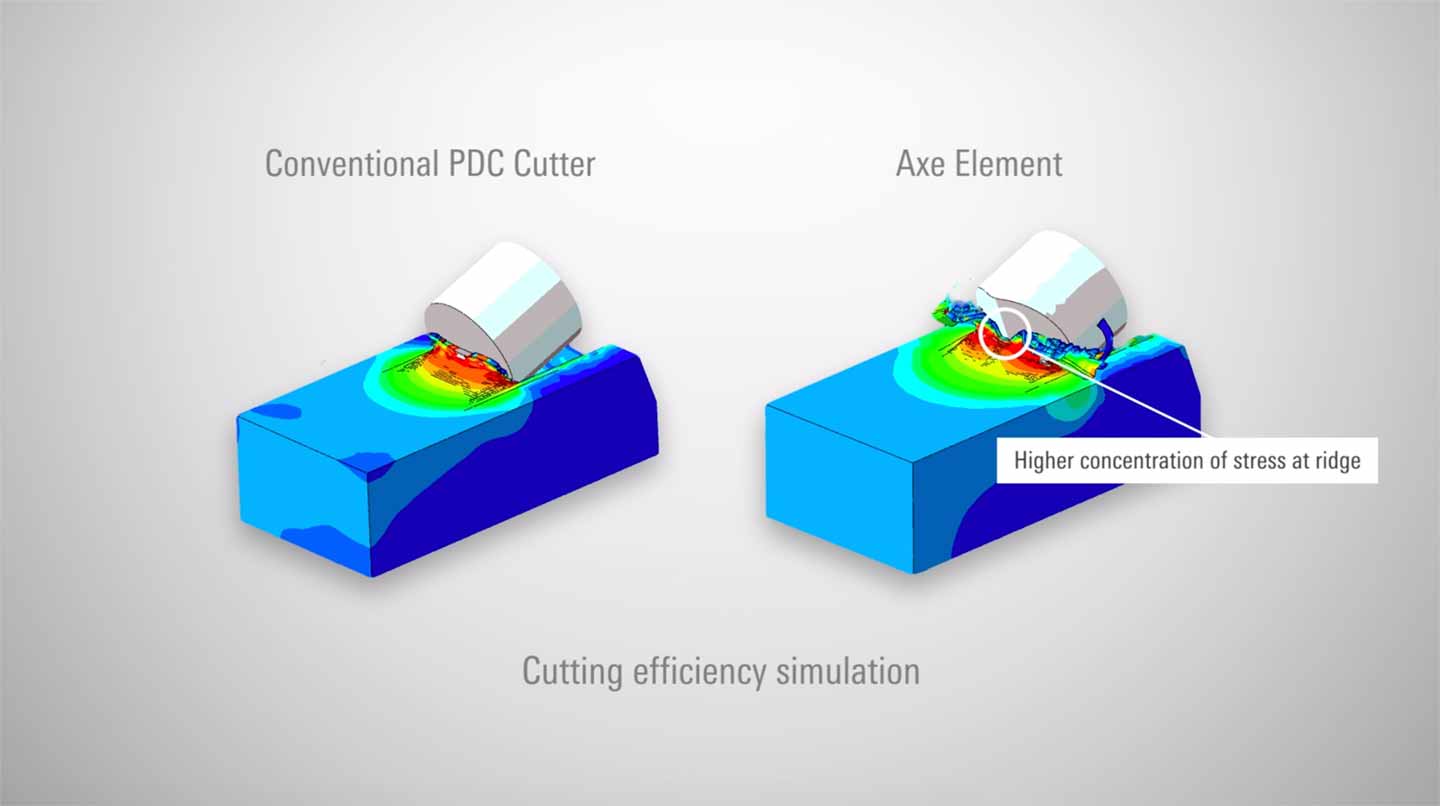

To reduce this stress, we developed a ridge-shaped cutter that has a lower torque response for a given depth of cut or ROP. This innovation went above and beyond just what the bit is required to do: it created less stress across the BHA and prevented the downhole tools from being exposed to stressful environments.

This is just one example of the things we’ve done to help. Smith Bits tackled multiple different challenges on a macro level, and we wanted to have a specific technology for each one of those unique challenges. In summary, we needed designs where we could see significant improvements over conventional PDC bits in almost any application.

Many times, sections require multiple bits due to excessive cutter wear causing a drop in ROP. In more abrasive applications, that’s where we would offer a PDC bit with ONYX 360 cutters.

In a multi-bit scenario, it’s best to have cutters that are able to rotate and distribute the wear that limits the performance of a conventional PDC bit. With a PDC bit using ONYX 360 cutters, the cutting elements rotate downhole, so we’re able to use the entire circumference of the cutting edge, compared to a conventional PDC cutter which is brazed in and stationary. Conventional PDC cutters use approximately 20% of the cutting edge, which accelarates the wear damage and reduces ROP. The PDC bit with ONYX 360 cutters lets us use a fresh edge and more diamond material. So the bit can drill further in abrasive applications before it starts to create wear damage slow down.

A StingBlade conical diamond element bit—which uses Stinger elements— would be used for the impact-prone interbedded formations, harder carbonates, and conglomerates. This also includes transitional drilling, where the operators drill through a long section with multiple layers of different formations, and they’ll drill very, very fast through a softer shale. The bit hits a harder formation at a high ROP, which causes impact damage to the cutters. That is when the bit slows down and they have to pull it out before reaching the section TD. The StingBlade bit would mitigate this damage and extend footage to reduce bit trips in many similar applications.

Whenever we ran the ONYX 360 and the StingBlade bits, we saw a significant improvement in bit durability to reduce bit trips. But almost 60% of sections drilled today only require one bit, so our opportunity to reduce the customer’s drilling costs for these applications needed to come from higher ROP.

So that’s where enabling technology, the Axe ridged diamond element, took its form. We wanted to further improve the ROP, the overall cutting efficiency, how much formation we can remove for a given energy input, weight on bit, and rpm. In addition, there are many other applications where torque and stick/slip, for instance, are an issue. Obviously, torque is primarily created by the bit. And high torque can cause issues like overall stress on the BHA components as I mentioned before, as well as steerability.

With the AxeBlade bit, we can dig deeper into and remove more formation than a conventional PDC cutter at a given input energy. That’s the main benefit.

We’re continually making the specialized bit technology we have better and better, just like we do with our conventional PDC cutter technology.

From the material side and the overall robustness—the strength of the element, the wear resistance, and the impact resistance of each element—we want to continually improve our products and services to help our customers reduce their drilling costs.