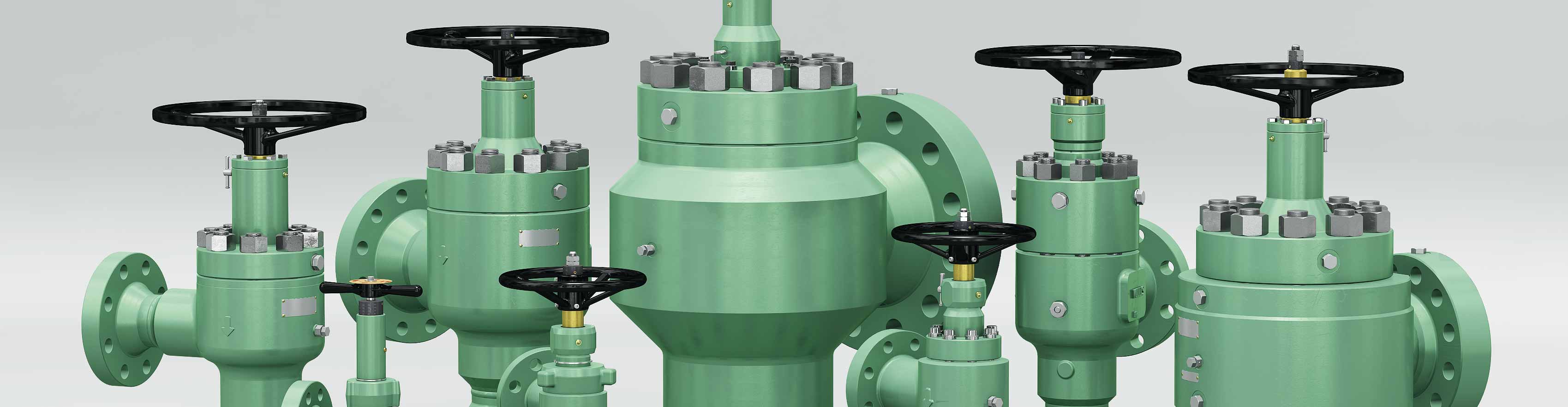

External Sleeve Control Choke

For low-capacity, high-pressure-drop applications

The external sleeve control choke has a sleeve that throttles the flow on the external diameter of the ported cage. The external sleeve trim is particularly suited for low-capacity/high pressure-drop applications. The external sleeve is designed specifically for severely erosive service where the combination of high pressure drops and high sand concentrations can reduce the life of a choke.

- Available in various sizes ranging from CC15 to CC80 choke models.

- Tungsten carbide-lined external sleeve and solid tungsten carbide cage/seat provide optimum wear resistance in erosive conditions.

- Metal body-to-bonnet gasket for absolute pressure containment.

- Reverse angle external sleeve improves flow dynamics within the trim.

- Self-flushing, pressure-balanced ports reduced stem loads and actuator output requirements.

- Heavy-duty thrust bearings reduce operating torque.

- Pressure-balance seals are a key feature of the pressure-balanced trim arrangement, reducing operating forces and enabling greater ease of adjustment.

Features

- Large visual indicator provides position in 1/64 in (bean) as standard.

- External grease port lubricates threads and bearings.

- Stem lock maintains set position.

- Bleed plug assembly vents pressure before disassembly.

- Antirotation key translates rotation from the drive bushing into linear movement of the lower stem/flow plug assembly.

- Two-piece stem is threaded and locked, and is removed from wellbore fluids.

- Large annulus area reduces the risk of body and trim erosion caused by high velocities.

All control chokes are available in manually operated or actuated models. Custom-designed trim components to suit a wide variety of Cv capacities and flow characteristics also are available.