Intelligent Flowback System

Choose from a range of options to control well flowback and acquire critical flow data in real time

Remote, automated, or closed-loop control to suit your requirements.

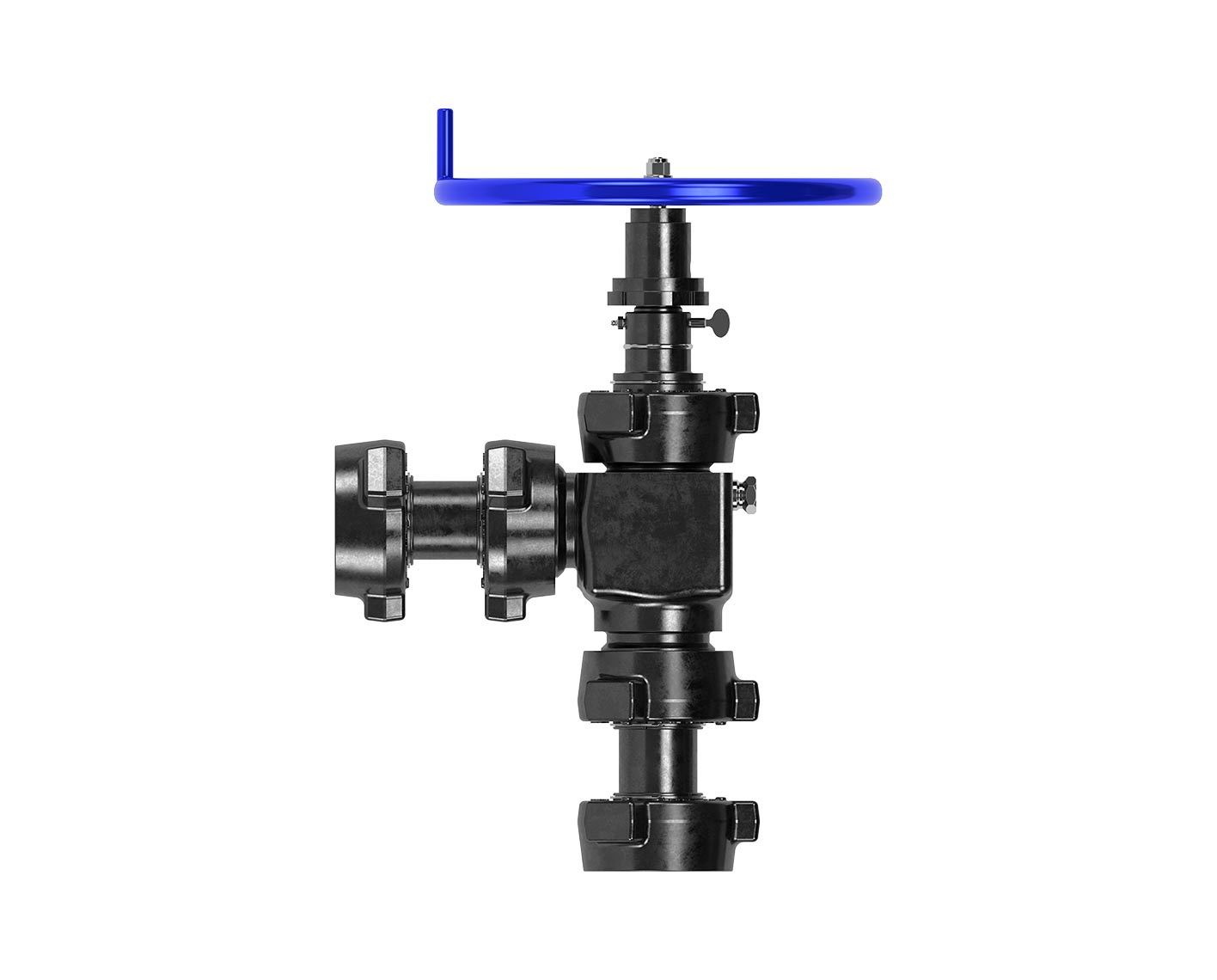

With multiple trim options to suit changing conditions, our multitrim flowback choke valves accommodate a wide range of oilfield operations. Their modular design and easily interchangeable trim styles enhance versatility. Further, their adaptability for various modes of actuation enables you to change the actuation type in the field without disassembling the choke, minimizing downtime.

Chokes are frequently exposed to erosive wear because of sand and other particles in the production fluids. If left unattended, washouts and choke failures can result, endangering personnel, environmental safety, and production. Multitrim chokes offer full trim interchangeability, supporting planned maintenance for increased uptime. A replaceable needle tip and external sleeve trim further facilitate maintenance.

Changing trims saves the time and cost associated with purchasing a different type of choke when well conditions change. Multitrim shale choke valves have a significantly extended service life and enhanced control owing to innovative trim design and the use of advanced materials. The result is more efficient production and less formation damage.

CAM20-FB multitrim choke valve

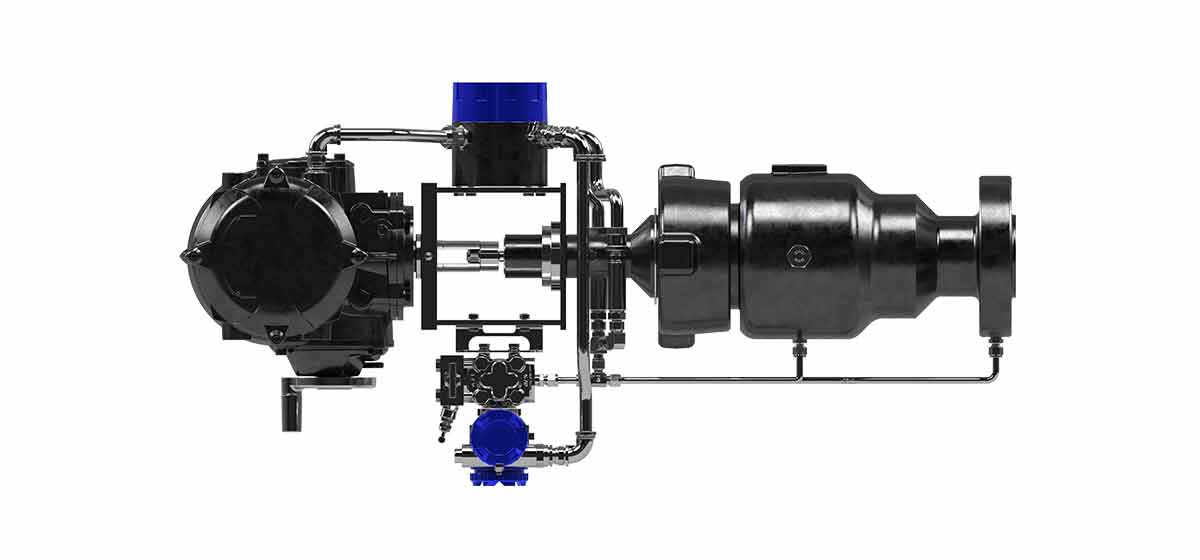

CAM30-FB multitrim choke valve

Explore how the Modum Flow™ flowmetering system enables you to respond quickly to production changes, reduce well testing schedules for stable wells, and focus more testing resources on wells where changes have been detected.

Learn more