Tech Paper Restoration of High-Temperature Well Integrity

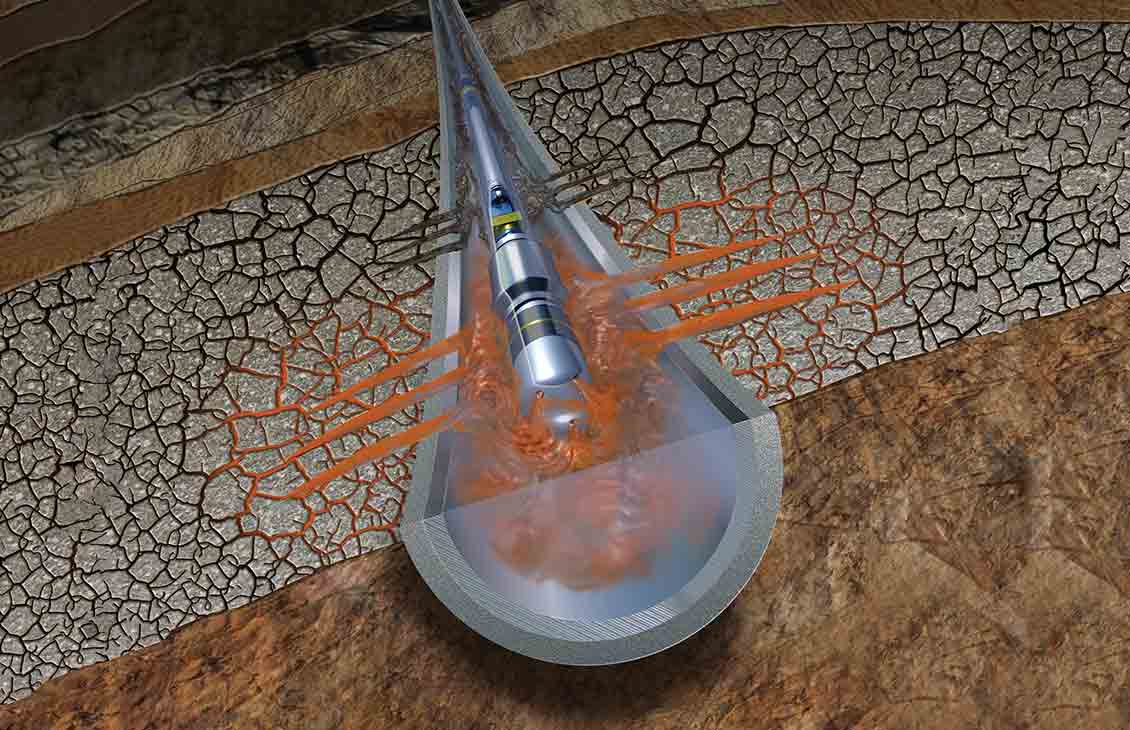

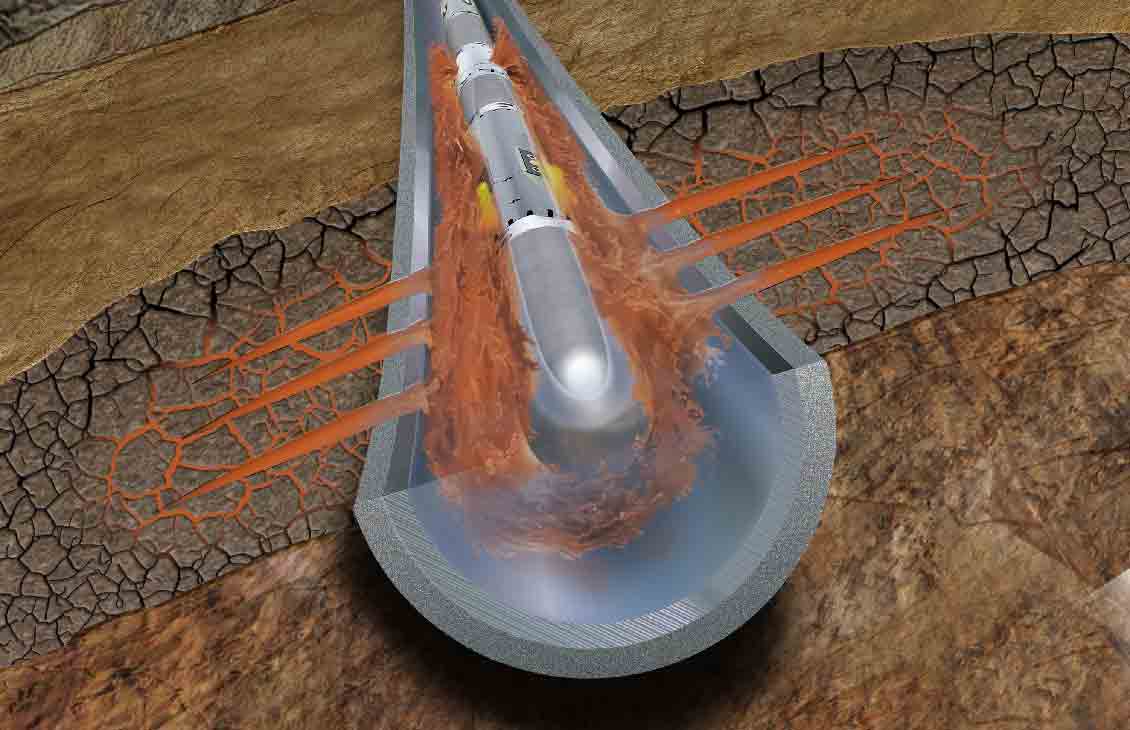

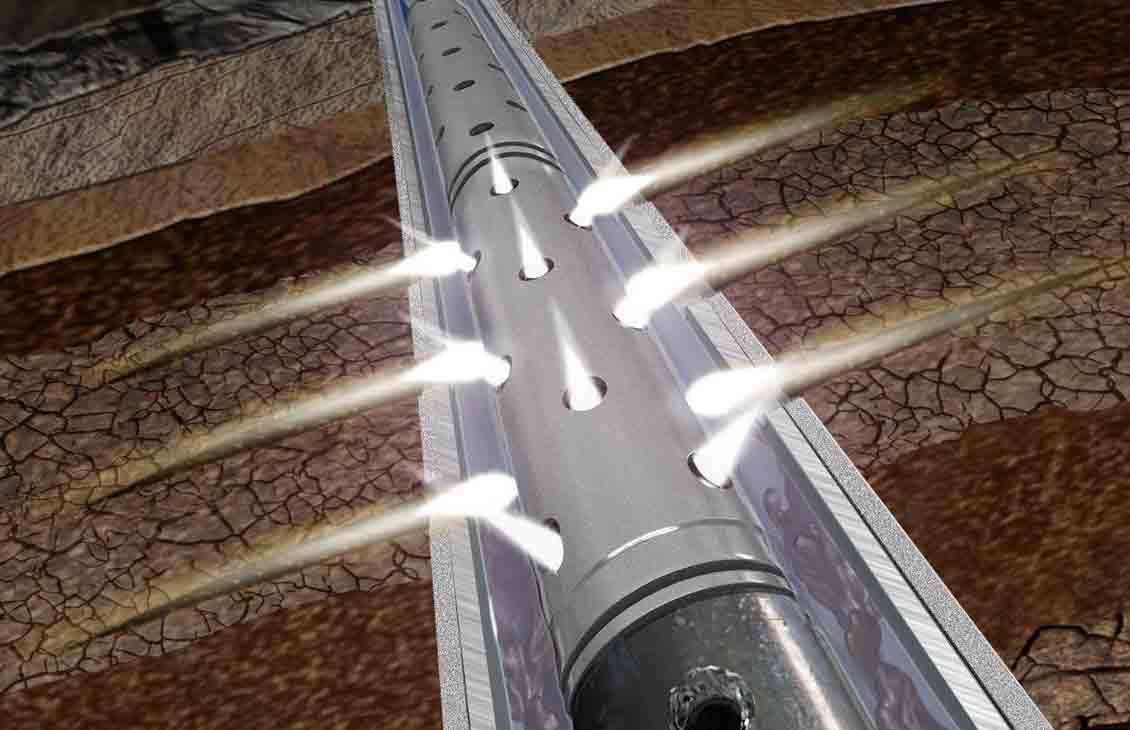

Real-time CT services and expandable steel patch repair tubing leak in high-rate gas well.

Real-time downhole coiled tubing services

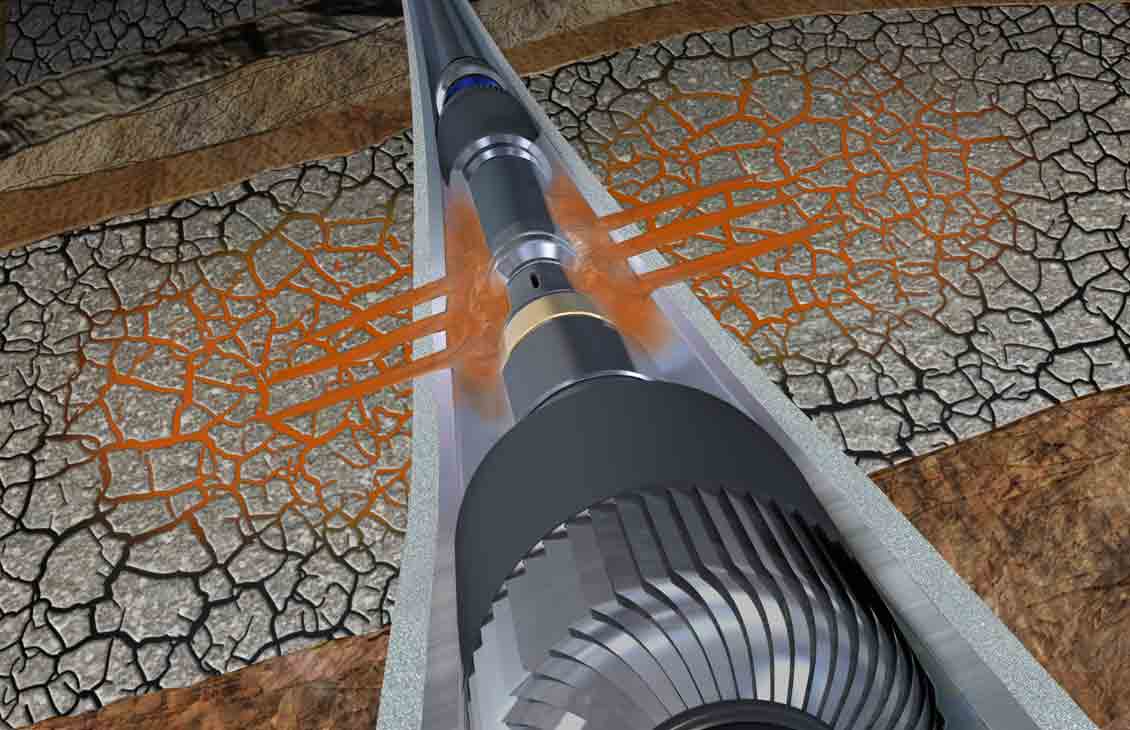

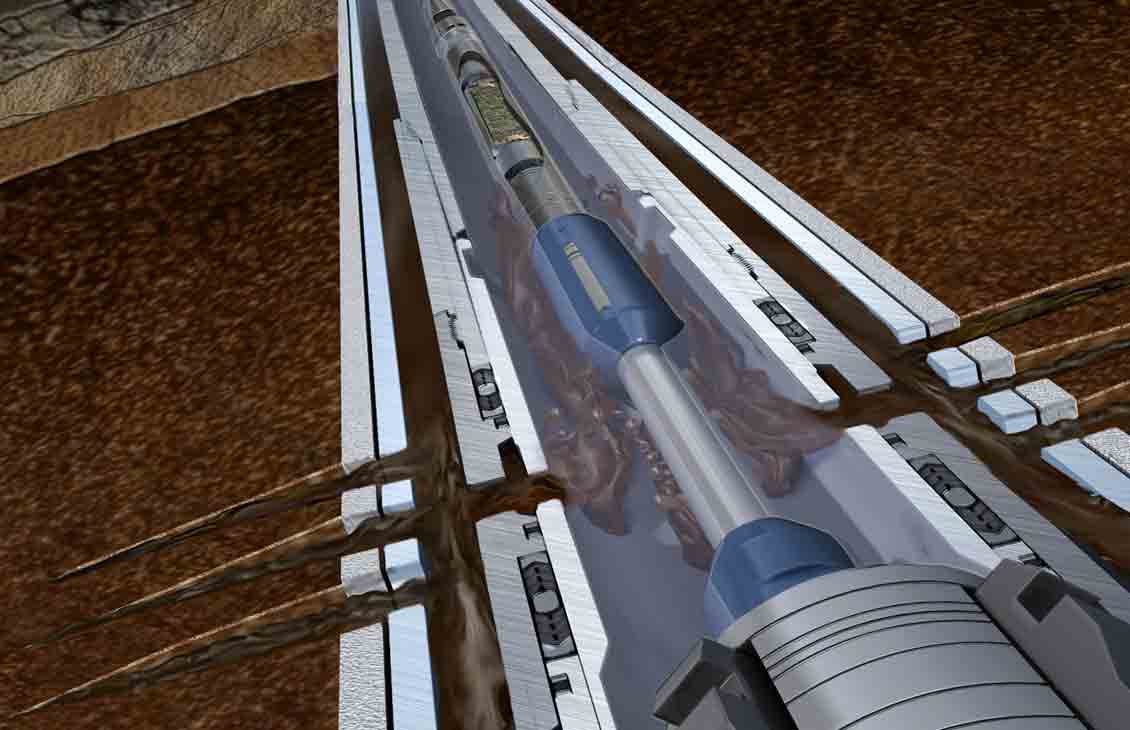

ACTive real-time downhole coiled tubing services monitor and evaluate treatments while they are still in progress for better optimization—and with one trip downhole.

Consequently, the well is more quickly returned to production, minimizing well downtime.

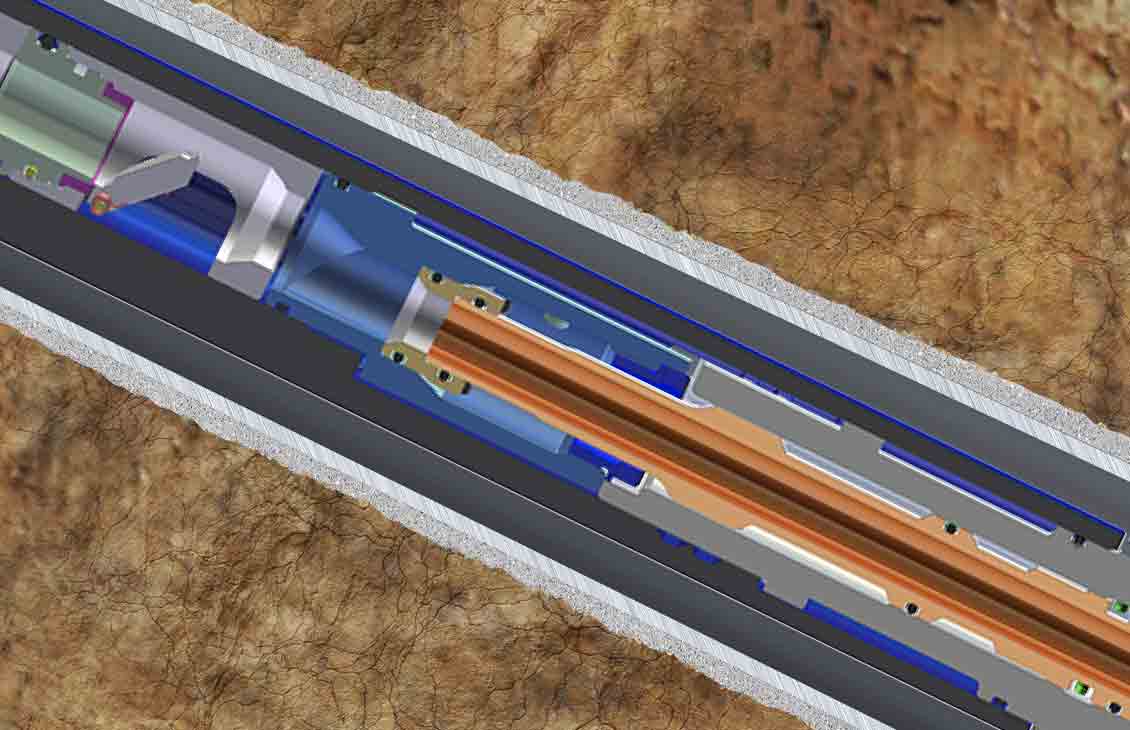

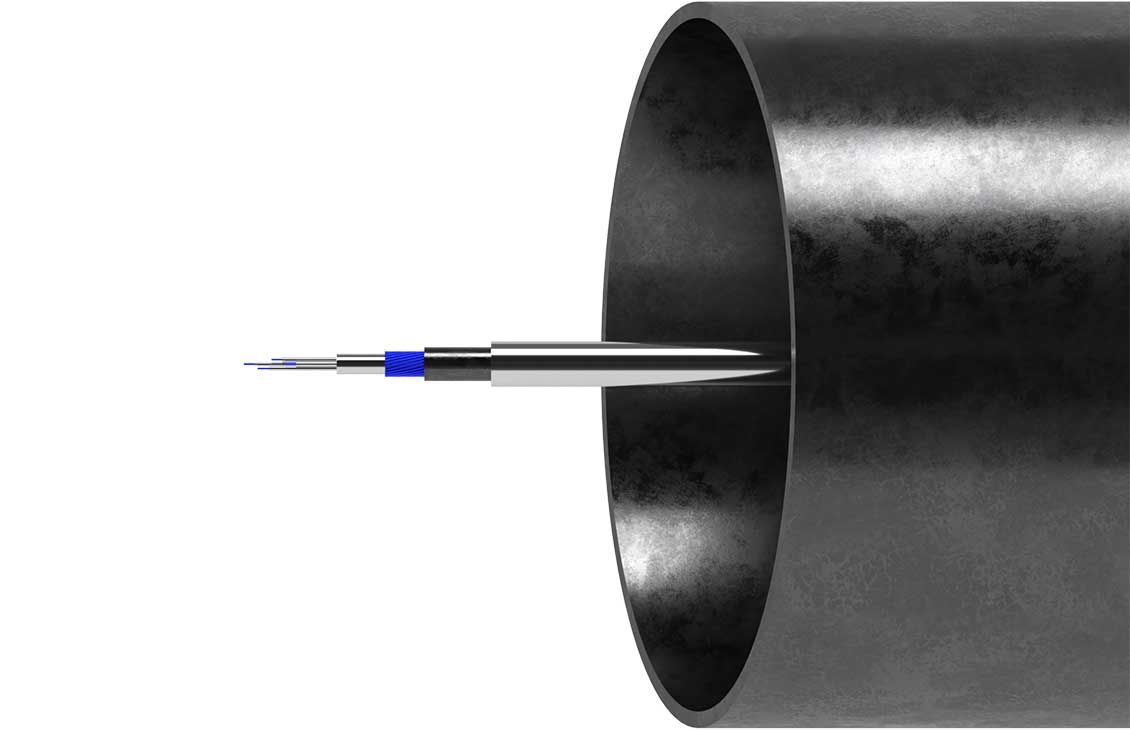

The service uses fiber-optic, telemetry-enabled CT consisting of a BHA, surface electronics, and dynamic interpretation software. This enables ACTive services to deliver internal and external pressure, temperature, and casing collar locator and gamma ray depth correlation. Force measurements from the tension and compression tool and a DTS survey are also performed.

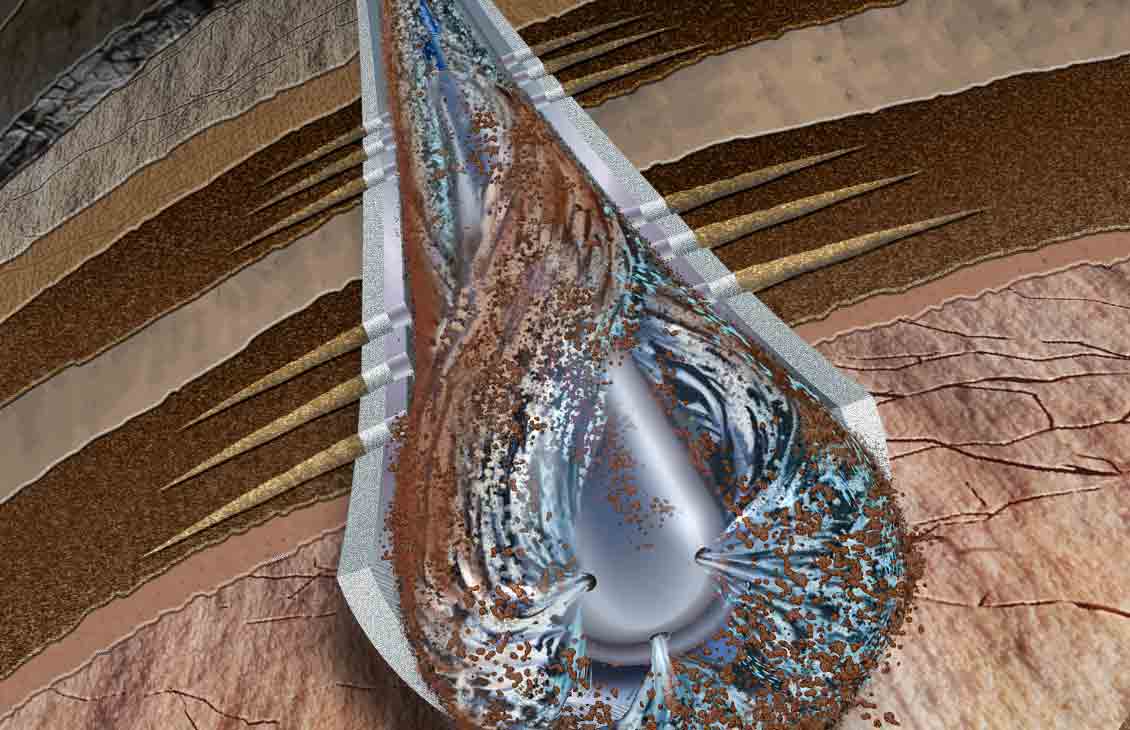

In turbulent times, optimizing the performance of existing wells is a practical choice that reduces the costs and risks associated with well intervention. Innovative coiled tubing technologies offer several key benefits, including reduced footprint, accurate measurement of bottomhole pressures and temperatures, proper depth correlation, and precise load measurements in a unique, robust package for harsh environments and complex systems.

Download PDFReal-time services that are run on ACTive CT systems.

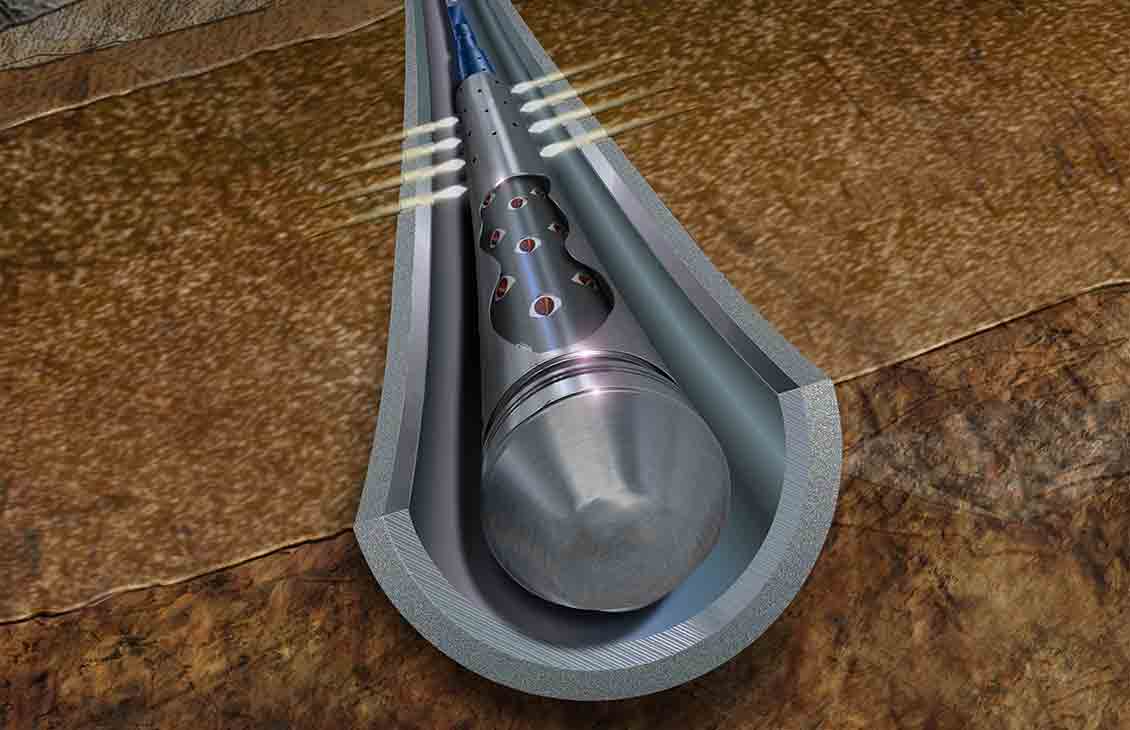

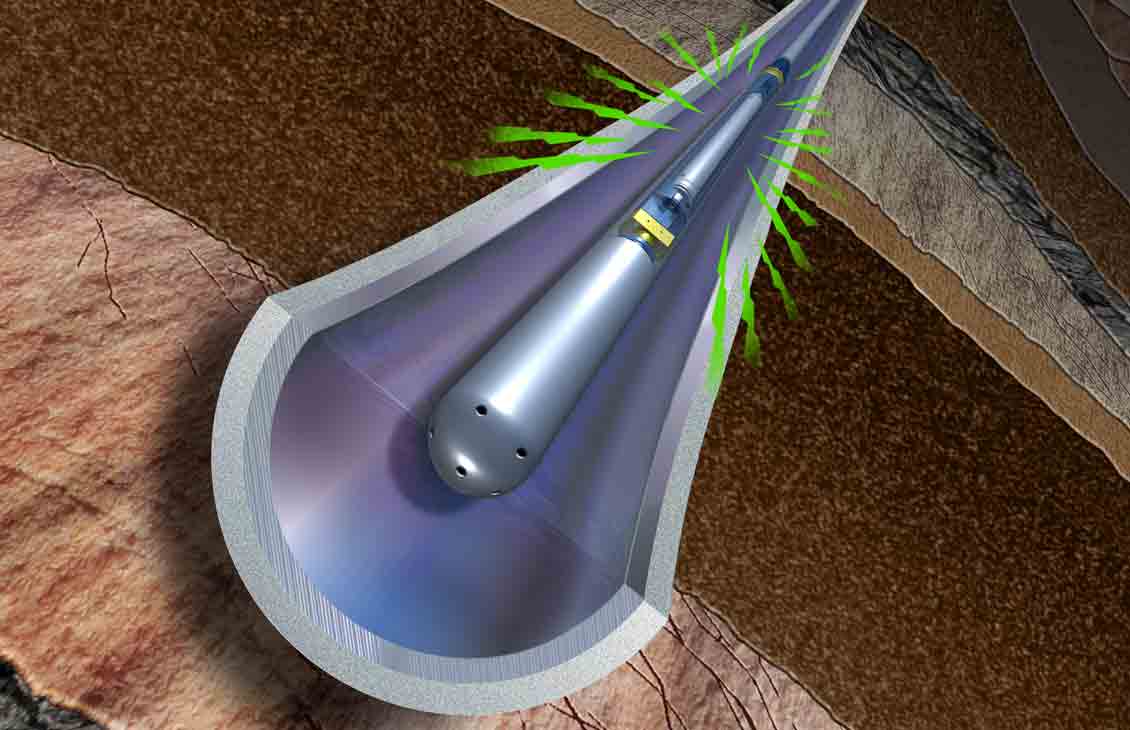

Enable single-run depth setting, sealing element operations, packer force monitoring, and fluid placement. View

Support strategic decision making with measurements taken during intervention operations. View

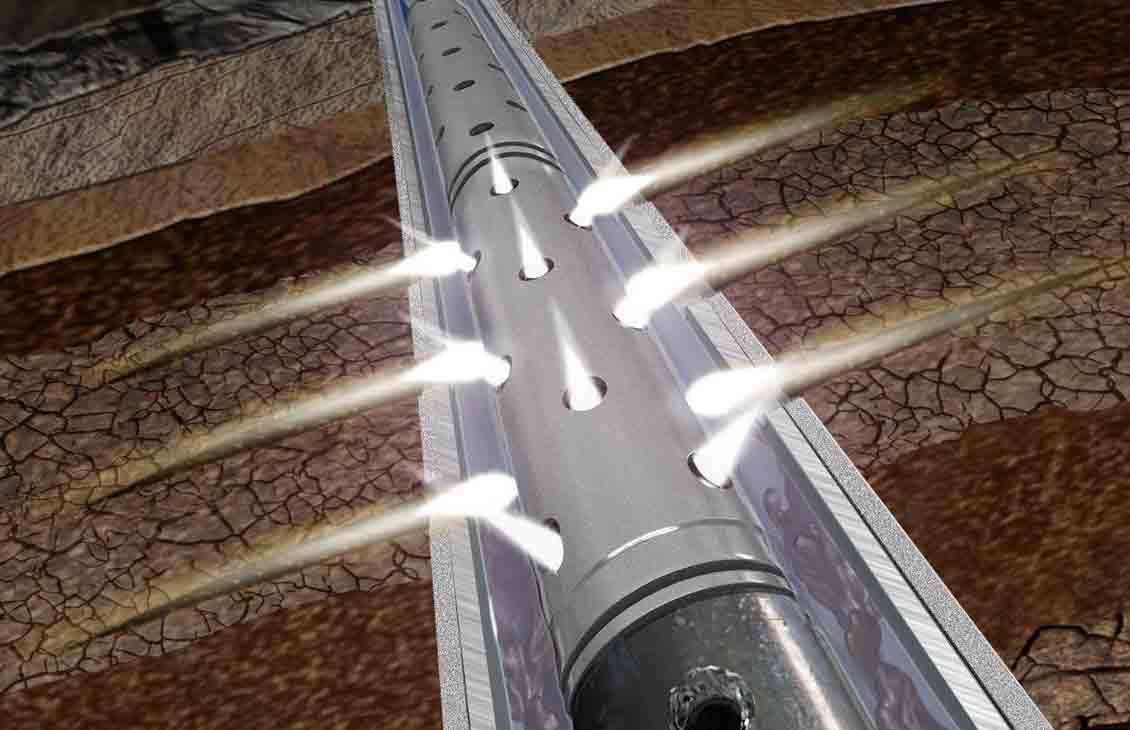

Ensure target zone coverage with selective perforating, and achieve accurate depth control in a single run. View

Optimize CT stimulation matrix using live monitoring of injection rate, downhole pressure, and temperature. View

Quantify the intake profile of treatment fluid along the wellbore. View

Couple real-time fiber-optic telemetry with existing advanced wireline production logging tools. View

Acquire high-quality fluid velocity data with the ACTive DFLO tool, comprising two sensor arrays. View

Eliminate the need for ball drop, pressure pulse, and dependence on pumping fluid for gun detonation. View

Real-time tools that are used to run the ACTive services.

Achieve real-time downhole fluid velocity and direction detection while maintaining pumpthrough capability. View

Detect naturally occurring gamma rays in adjacent formations while maintaining pumpthrough capability. View

Minimize CT toolstring complexity and simplify rig-up. View

Activate up to 10 times with precise downhole depth and hydrostatic pressure control—all in a single run. View

Deliver power for downhole tools, enabling more efficient and battery-free intervention operations. View

Improve job efficiency and subsequent well performance with real-time downhole measurements. View

Achieve a rugged high-pressure seal at high inflation ratios. View

Measure real-time downhole load and torque while maintaining pumpthrough capability. View

Operate in harsh, abrasive, and corrosive downhole conditions as well as HPHT and high shock loads. View