ACTive Plug & Perf

CT real-time plug setting and perforating system

Eliminate the need for ball drop, pressure pulse, and dependence on pumping fluid for gun detonation.

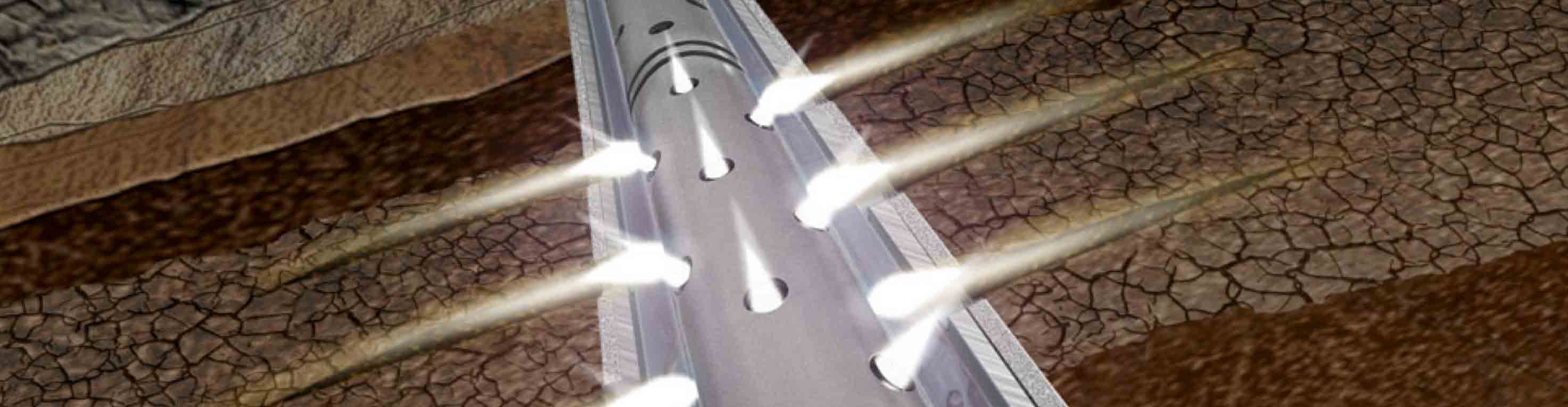

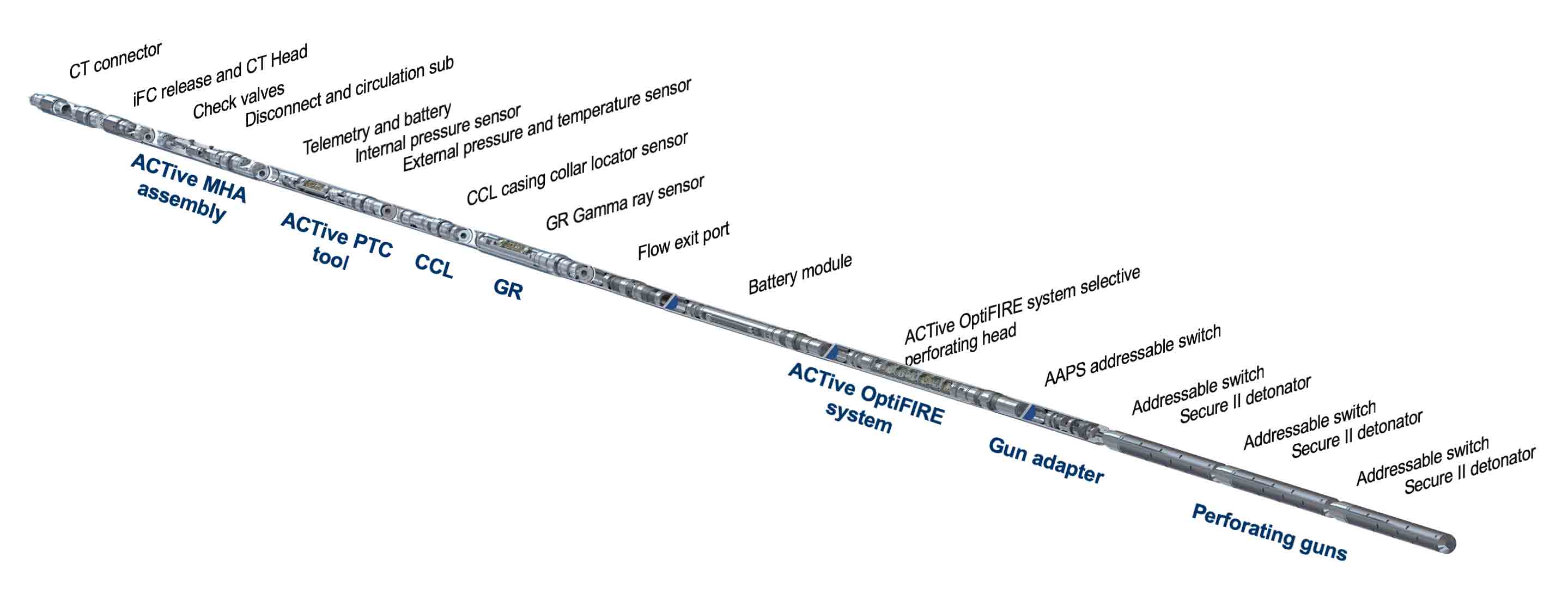

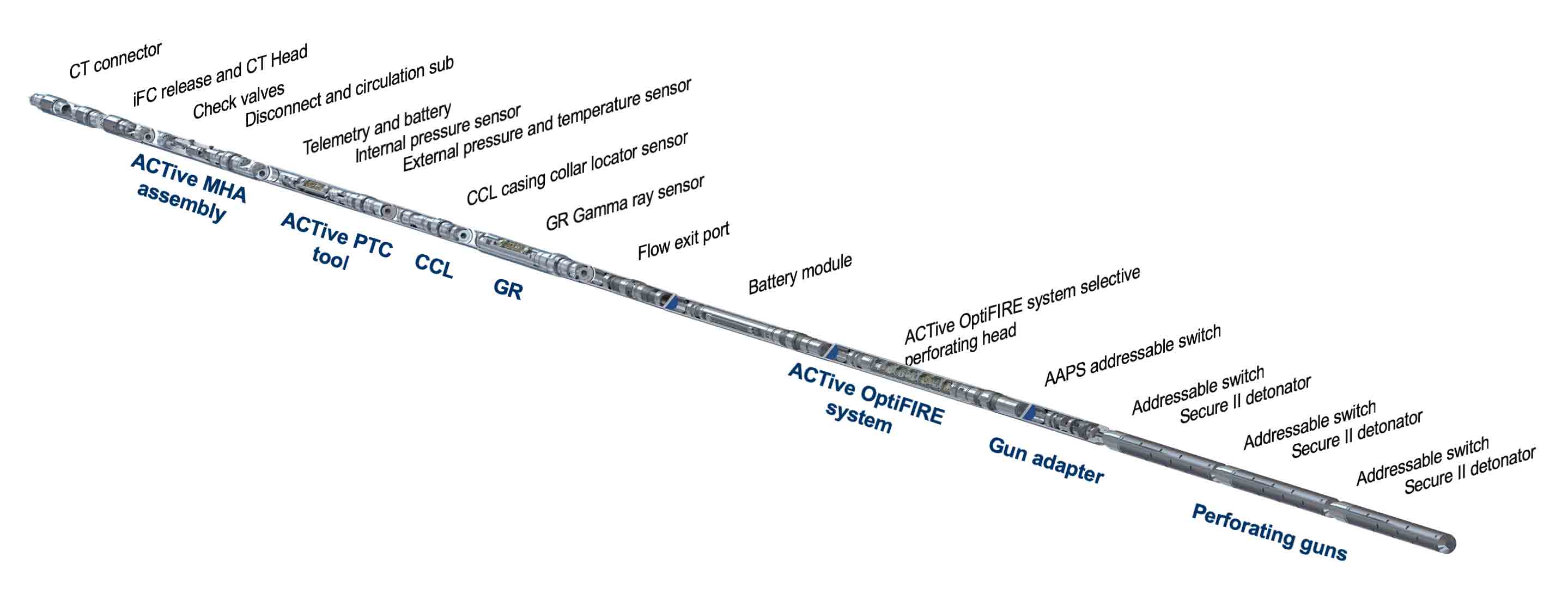

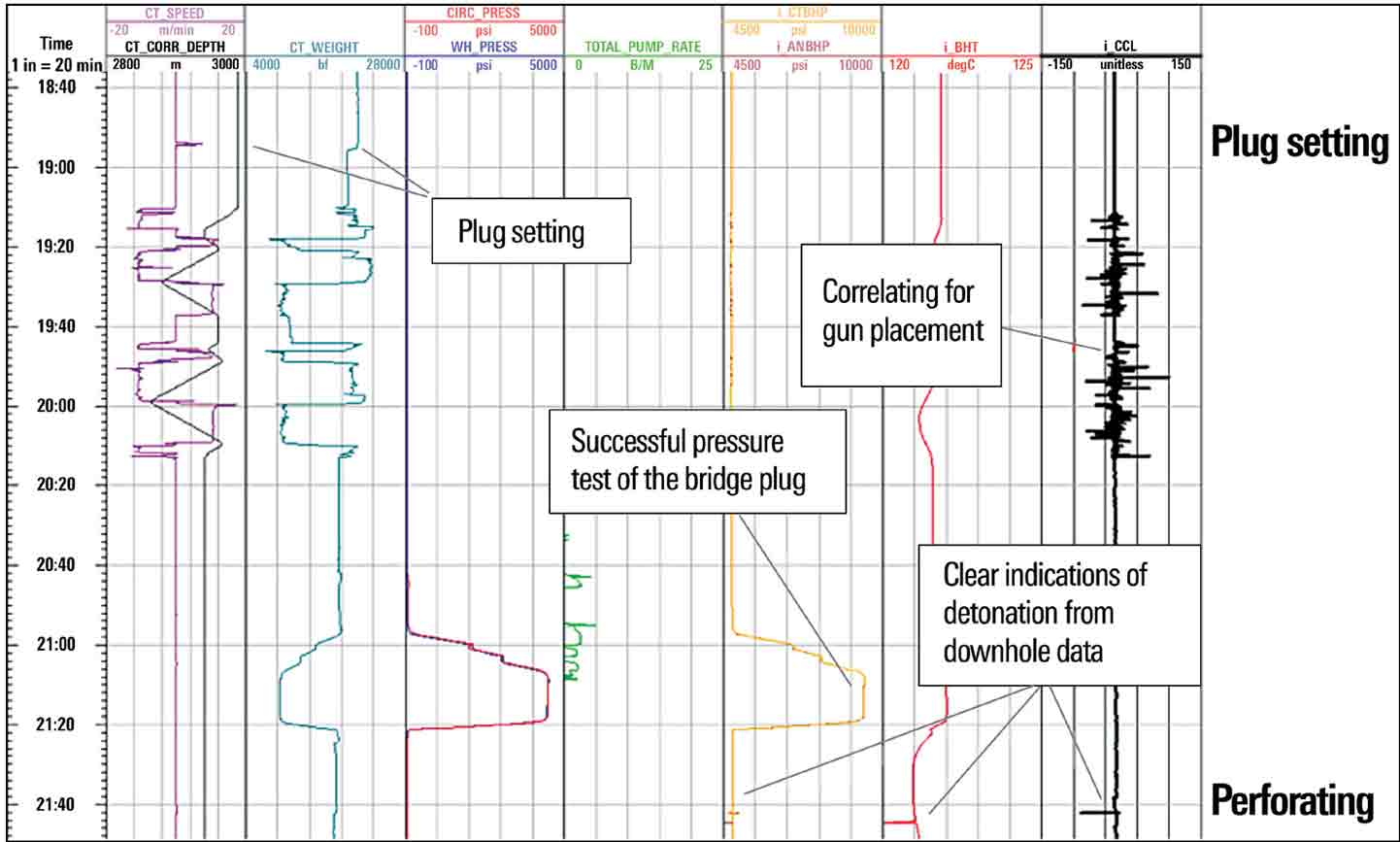

The ACTive OptiFIRE CT real-time selective perforating and activation system’s perforating guns can be activated up to 10 times with precise downhole depth and hydrostatic pressure control—all in a single run. Fewer runs for single-perforation attempts reduce downtime, minimizing costs and risk.

Unlike conventional perforating heads operated by hydraulics, the ACTive OptiFIRE system does not require pumping fluid for activation and wellbore fluid circulation, making it well-suited for subhydrostatic wells, high-flow-rate wells, and unstable or fluid-sensitive formations.

New technology sets Copperhead plugs and fires perforating guns with just one coiled tubing run, saving USD 600,000 in rig time, Congo

Read Case StudyThe system does not require a ball drop or a pressure pulse system to detonate and can be used with a wide range of perforating guns that are compatible with Secure2 RF-safe electronic detonators and addressable switches. The surface system selectively fires individual guns from the bottom up without pumping fluid, and detonation is confirmed in real time through built-in sensors, such as pressure, temperature, casing collar locator, and accelerometer—improving overall safety.