DropShift and DropShift Express

Frac sleeves

How it improves wells

DropShift* frac sleeve and DropShift Express* open-only frac sleeve enable continuous fracturing operations in multistage wells, improving stimulation efficiency, precision, and economics as compared with conventional plug-and-perf operations. DropShift sleeve also enables subsequent zonal shutoff to restrict water production or simplify selective zonal restimulation. The result is a longer producing life for the well.

As compared with conventional plug-and-perf technologies, DropShift and DropShift Express sleeves improve stimulation efficiency, precision, and economics. Because the sleeves are run into the well ahead of the stimulation operations, wireline is not required on location during stimulation. In addition, the large flow-through ID eliminates the need for poststimulation milling in most cases as frac balls are flushed back to surface or, in the case of degradable balls, dissolve completely. If milling is required, then the large ID eliminates concerns about milling debris flowback.

Both sleeves also reduce water consumption at the wellsite by eliminating water flushes typically required between plug-and-perf operations. The more accurate frac placement, as compared with plug-and-perf methods, reduces horsepower requirements and emissions during stimulation operations. The ability of DropShift sleeves to shut off water production later in the life of the well also eliminates concerns about treating or disposing of produced water.

Because they are shorter than conventional frac sleeve technologies, DropShift and DropShift Express sleeves are easier to install, which improves well construction efficiency. The sleeves’ large frac ports enable high fracturing and production rates.

How it works

Run into the well as part of the liner system, DropShift and DropShift Express sleeves are consecutively opened during stimulation by dropping progressively larger balls from surface. The large frac port area maximizes the potential stimulation rate and reduces erosion. After stimulation, the balls either float off the ball seats or, in the case of dissolvables, dissolve completely to leave the well open for production. If milling is required, the proprietary alloys and antirotational design ensure ball seats can be easily milled out after stimulation to leave the full bore open for production.

DropShift Express sleeves are open-only. However, if the DropShift sleeves are installed, they can be reclosed later in the life of the well by running a compatible shifting tool on coiled tubing or conventional tubing. This enables selective water shutoff, depleted zone shutoff, or zone-by-zone restimulation.

What it replaces

- Longer frac sleeve technologies that are more difficult to install in horizontal and deviated wells and less versatile for later shutoff and recompletions

- Conventional frac plugs used in plug-and-perf operations

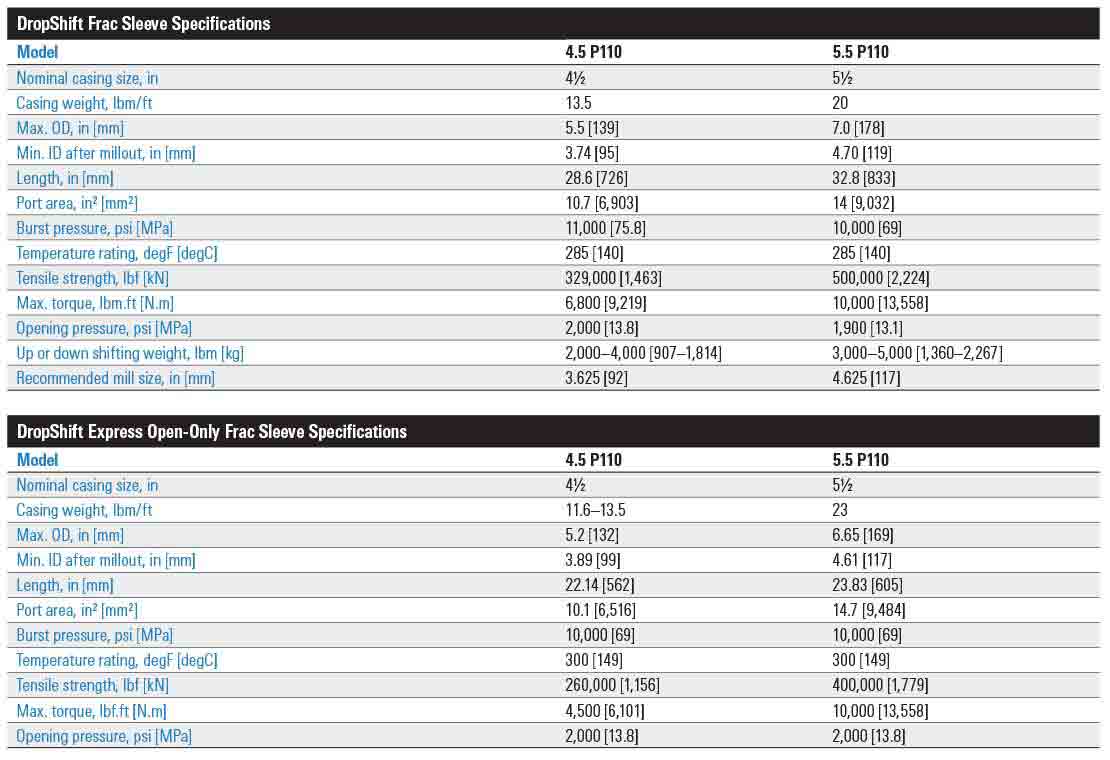

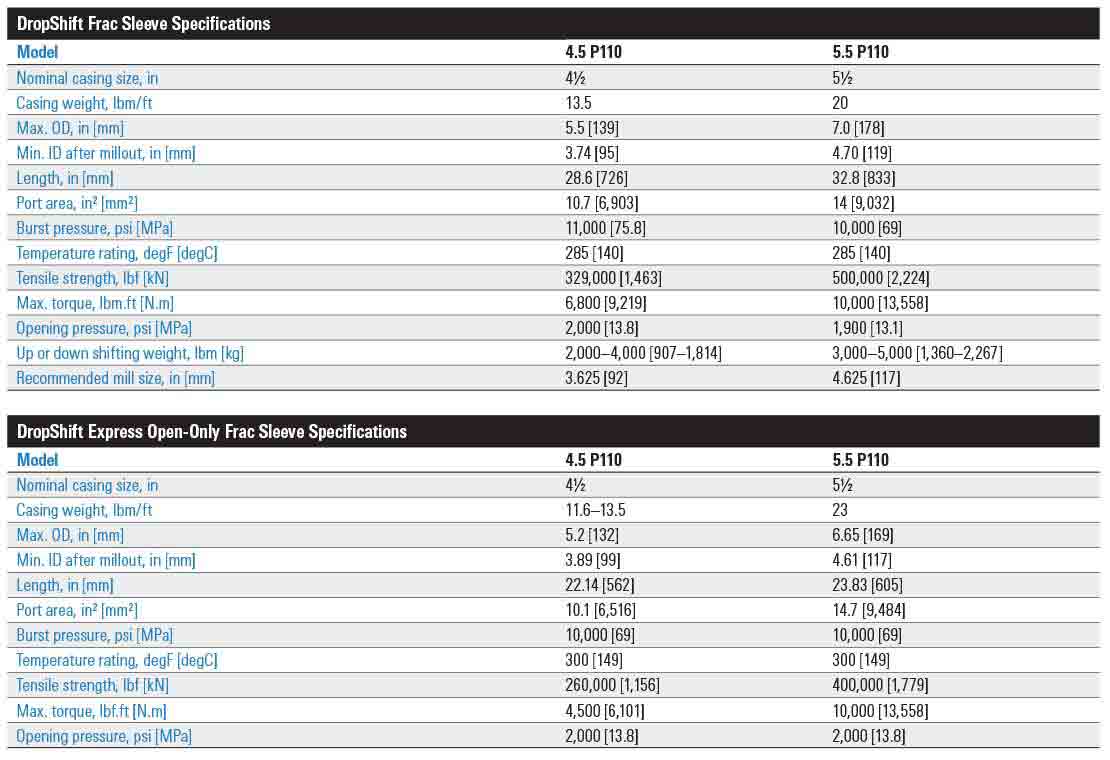

Additional information Featuring field-interchangeable ball seats, DropShift and DropShift Express sleeves are easy to configure at surface. Both sleeves are compatible with dissolvable or millable balls. Sleeves are available in P110 or L80 metallurgy with premium elastomers and coatings on the sleeve ID to ensure longevity.