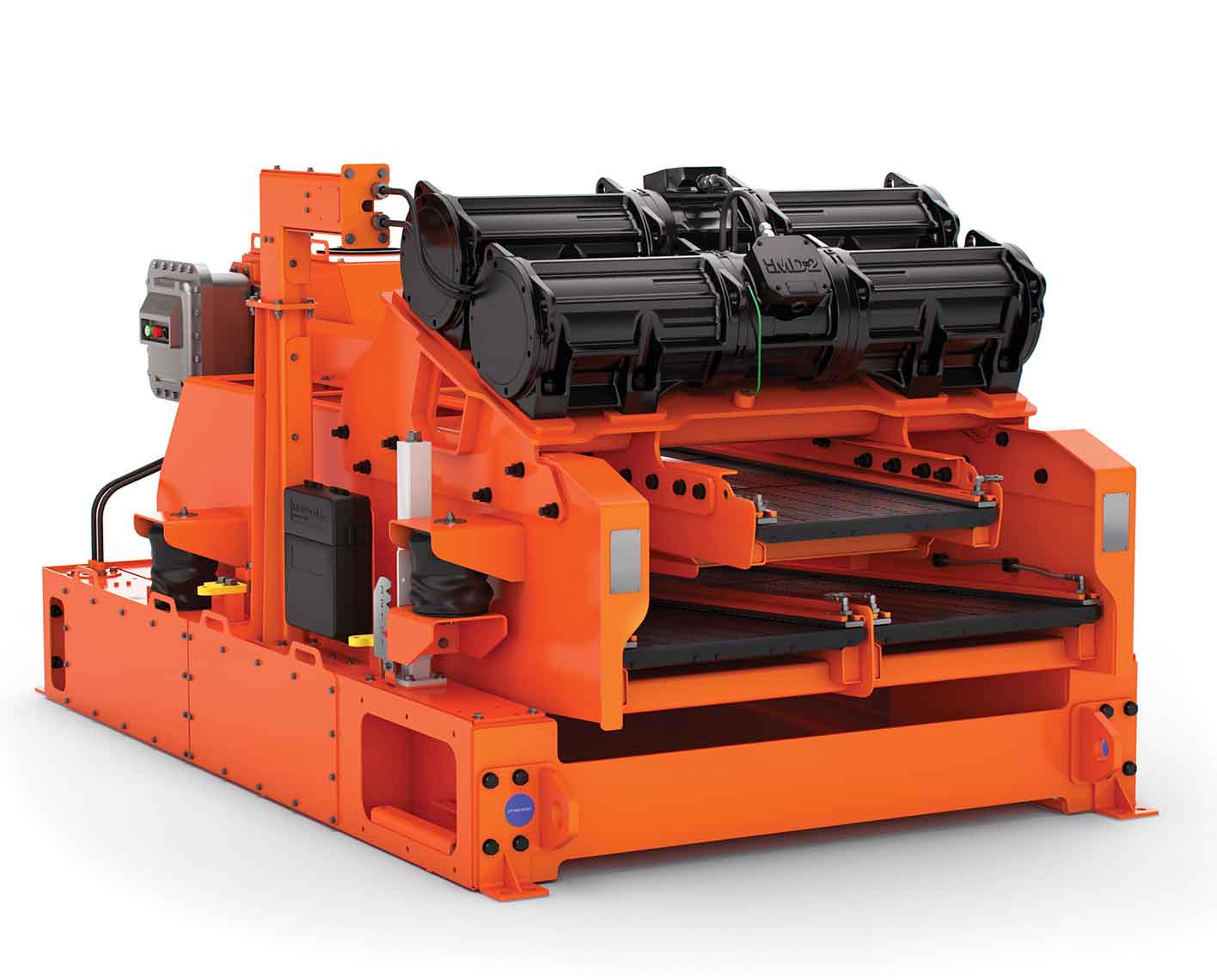

MONGOOSE Max

High-capacity shaker

Increase solids- and fluid-handling capacity by 35% and fluid recovery by 40%.

The uniquely engineered MD-2 dual-deck shaker equipped with patented DURAFLO composite replacement screens takes the solids control process to new levels of efficiency. The extended useful life of composite screens in tandem with the higher capacity of a dual-bed, flat-deck shaker assures a cost-effective and high performing solids control package.

Different drilling conditions require different acceleration rates and deck angles. For fluid surges and heavy solids loading, the MD-2 shaker is run in the capacity mode. This 7.5-G balanced elliptical motion is ideal when larger cuttings volumes require higher acceleration, an increased conveyance rate and thin ellipse motion across the entire screen deck. When maximum cuttings retention and dryness are required, the MD-2 shaker can be switched to the normal or efficiency mode. The 6.5-G acceleration of this progressive elliptical motion produces a thin ellipse motion that quickly removes solids from the mud, while a wide ellipse at discharge maximizes retention to produce drier cuttings.

The angles of the two MD-2 shaker decks also adapt easily to changing drilling conditions, different fluid types and varying solids. This for flexible control of both fluid pool depth and beach length. The scalping deck is adjustable between 1° to +3°, while the primary deck can be adjusted between a net range of +3° to +7°.

The MD-2 shaker is engineered specifically to capitalize on the longer life and enhanced performance of composite-frame DURAFLO screen technology. Unlike metal-framed screens, DURAFLO screens combine a polypropylene frame with an internal reinforcing cage made of high-strength steel. This rigid and novel design extends the screen while delivering higher conveyance rates, less stress on the shaker, increased fluid capacity and fewer screen change-outs.