Locks

Anchor and seal a pressure or flow control device in tubing strings

Choose a lock or accessory to suit your well conditions

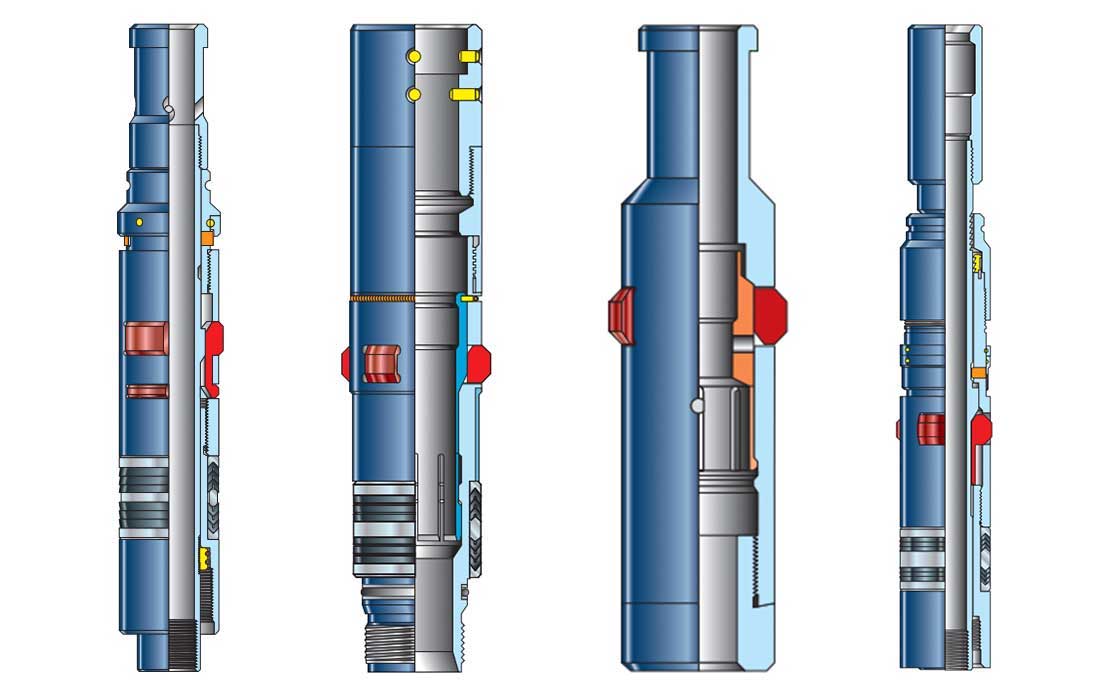

With a full product line of no-go locks, collar locks, and lock accessories covering most oilfield conditions, we can deliver the technology you need to suit your completion and downhole environment.

Install packoffs or plunger lift systems without a landing nipple

The Z-5 collar lock is used as a tubing stop in wells that have tubing collar recesses to set the lock (i.e., API coupled tubing joints). A landing nipple is not required. The lock has a straight-through bore and cannot be unset by high-velocity liquid or gas. It is ideal for use in packoff installations and as an anchor for the bottomhole bumper spring in plunger lift installations. A packing section can be attached to the lower end of the lock, together with any standard subsurface control. Download the Z-5 collar lock PDF

Install the lock in a landing nipple

Some locks are installed in landing nipples to seal and anchor subsurface flow or pressure control devices (e.g., standing valves, surface-controlled subsurface safety valves) in the tubing string. Various temperature and differential pressure ratings are available; download specific product PDFs for detailed specifications.

HPC-R high-pressure no-go lock

Absorb shock to prevent gauge damage

When a lock is to be installed in a landing nipple, a shock absorber can be connected between the lock and the pressure or temperature gauge suspended from it. The shock absorber prevents damage to the gauge by isolating it from the jarring action produced when setting and pulling the lock. Download the A-2 shock absorber PDF for additional details and specifications.