ESPs for Alternative Deployment

Enhance intervention efficiency

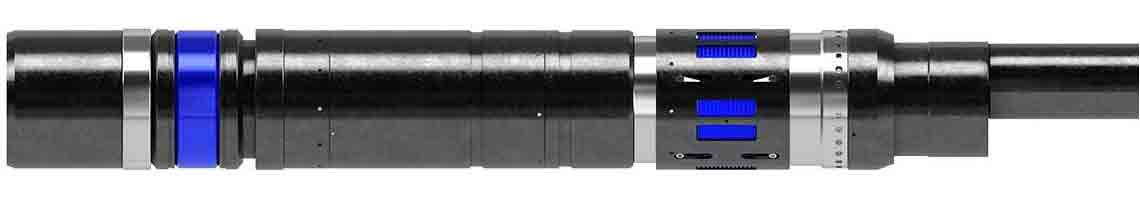

Use rigless ESP retrieval and deployment to optimize well production.

Reduce rig time and cost with simple setting and retrieval operations. No tubing movement is required while setting. The packer is installed with the completion tubing and set by applying pressure to the tubing. Retrieval is accomplished with a straight upward pull on the tubing. Set at the factory to a standard value, the packer shear-release mechanism can be adjusted in the field before installation. When the tension on the tubing string exceeds the predetermined value of the shear screws, the slips disengage the casing and the element relaxes.

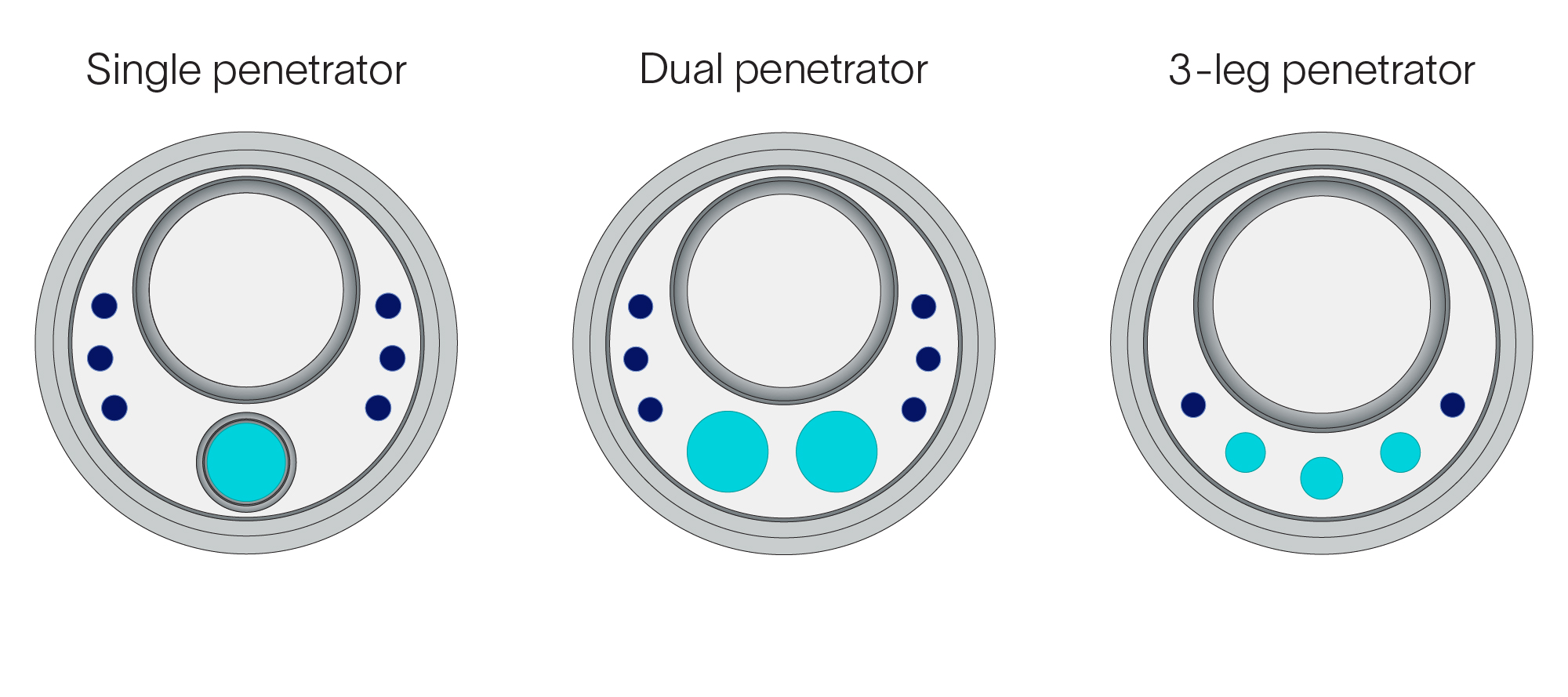

The modular architecture of our BluePack production packers simplifies engineering designs across the entire family.

You can select the packer that’s best suited for your well environment while configuring certain components and subassemblies of the packer based on the specific requirements or challenges of the well. For example, you might customize the elastomer based on the chemical properties of the fluids that will be in the well.

This standardization not only improves lead times and costs, it also improves operations by ensuring that employees are trained on a standardized deployment methodology.

Aflas is a mark of Asahi Glass Co., Ltd.